Phosphogypsum forest conditioner and method for preparing same

A phosphogypsum and conditioner technology, which is applied in the fields of botanical equipment and methods, plant growth regulators, preparation of organic fertilizers, etc., can solve the problems of inability to supply nutrients to trees, tree erosion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

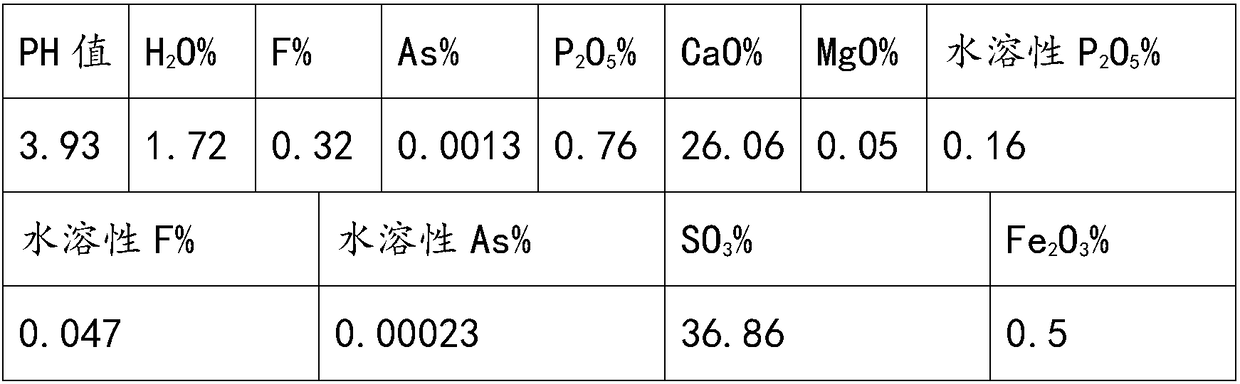

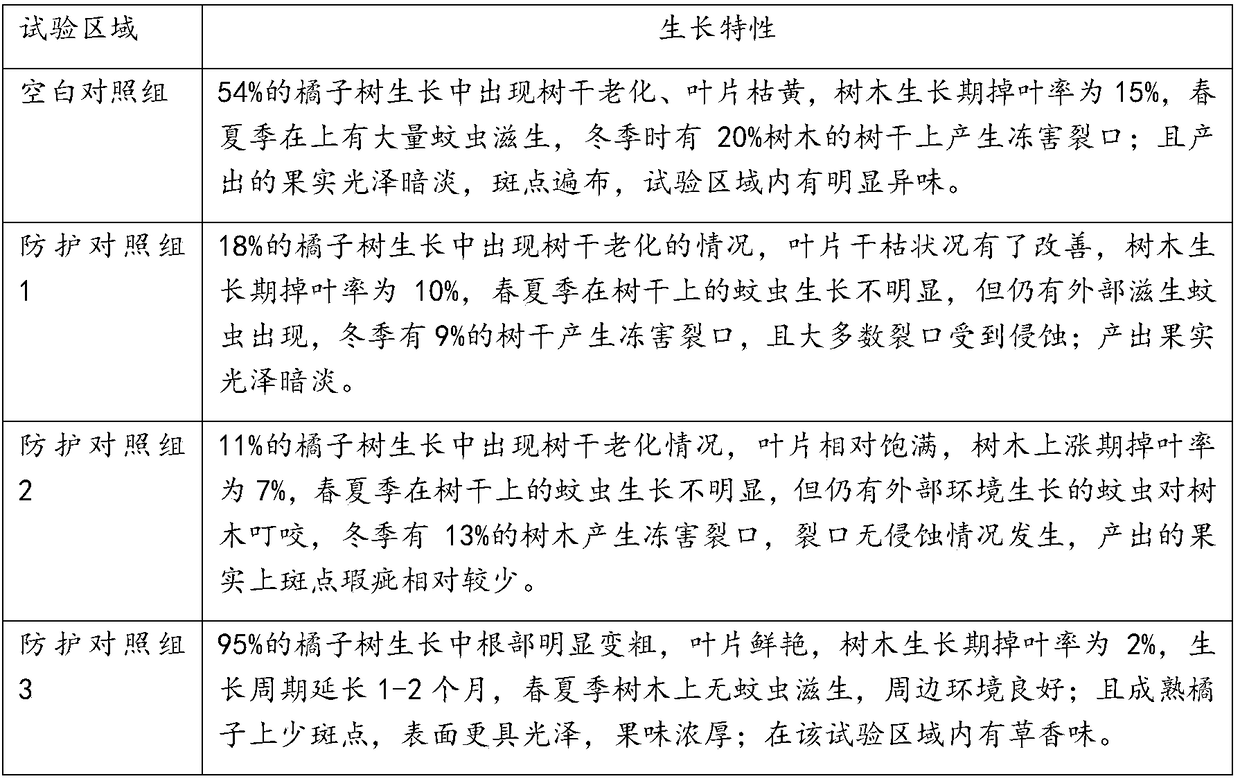

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of phosphogypsum tree conditioner of the present invention:

[0029] Raw material ratio: 80kg of phosphogypsum, 1kg of Coptis chinensis, 1kg of Artemisia annua powder, and 1kg of brown sugar;

[0030] Preparation:

[0031] (1) Get phosphogypsum and dry it, crush it through a 140-mesh sieve to get phosphogypsum powder for subsequent use;

[0032] (2) Brown sugar is dissolved in 4kg water to obtain brown sugar water for subsequent use;

[0033] (3) After drying and crushing Coptis chinensis, Artemisia annua powder and brown sugar respectively through a 30-mesh sieve, add the above-mentioned brown sugar water and phosphogypsum powder to mix and ferment, and the fermentation time is controlled at 40-60 hours;

[0034] (4) After the fermentation is finished, the fermented product is taken out, dried and pulverized to obtain the phosphogypsum tree conditioner.

Embodiment 2

[0035] Embodiment 2: the preparation of phosphogypsum tree conditioner of the present invention:

[0036] Raw material ratio: phosphogypsum 85kg, Coptis chinensis 2kg, Artemisia annua powder 3kg, brown sugar 1.5kg;

[0037] Preparation:

[0038] (1) Get phosphogypsum and dry it, pulverize it through a 120-mesh sieve to get phosphogypsum powder for subsequent use;

[0039] (2) Brown sugar is dissolved in 6kg water to obtain brown sugar water for subsequent use;

[0040] (3) After drying and crushing Coptis chinensis, Artemisia annua powder and brown sugar through a 60-mesh sieve, add the above-mentioned brown sugar water and phosphogypsum powder to mix and ferment, and the fermentation time is controlled at 40-60 hours;

[0041] (4) After the fermentation is finished, the fermented product is taken out, dried and pulverized to obtain the phosphogypsum tree conditioner.

Embodiment 3

[0042] Embodiment 3: the preparation of phosphogypsum tree conditioner of the present invention:

[0043] Raw material ratio: phosphogypsum 90kg, Coptis chinensis 3kg, Artemisia annua powder 2kg, brown sugar 3kg;

[0044] Preparation:

[0045] (1) Get phosphogypsum and dry it, pulverize it through a 150-mesh sieve to get phosphogypsum powder for subsequent use;

[0046] (2) Brown sugar is dissolved in 5kg water to obtain brown sugar water for subsequent use;

[0047] (3) After drying and crushing Coptis chinensis, Artemisia annua powder and brown sugar through an 80-mesh sieve, add the above-mentioned brown sugar water and phosphogypsum powder to mix and ferment, and the fermentation time is controlled at 40-60 hours;

[0048] (4) After the fermentation is finished, the fermented product is taken out, dried and pulverized to obtain the phosphogypsum tree conditioner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com