A kind of preparation method of porous nitrogen-doped carbon-coated graphite material

A technology of nitrogen-doped carbon and graphite materials, applied in structural parts, electrical components, battery electrodes, etc., to achieve good spreadability, excellent cycle performance and rate performance, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

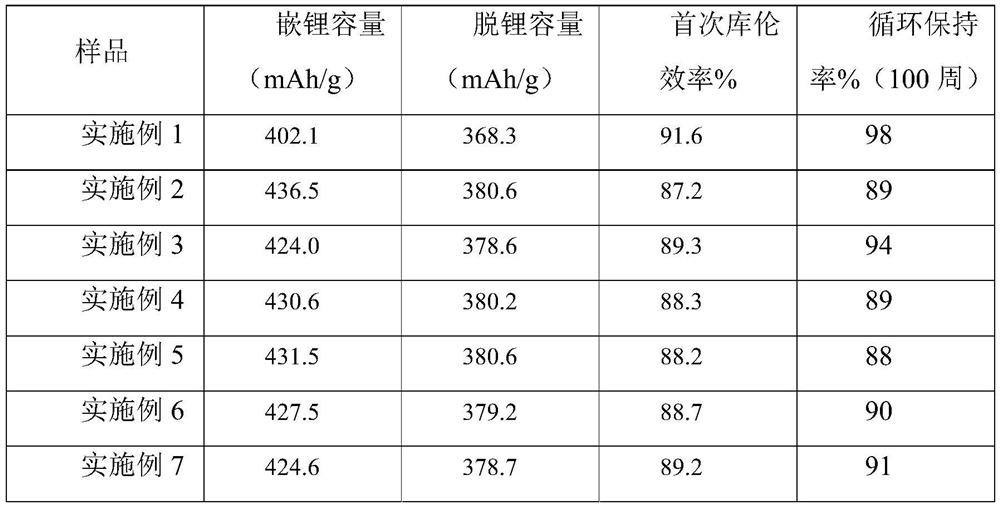

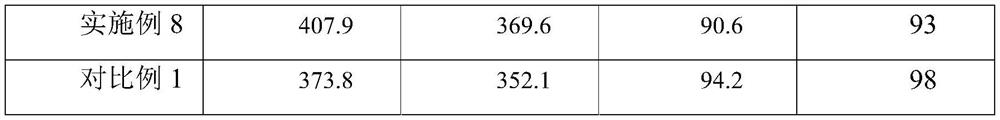

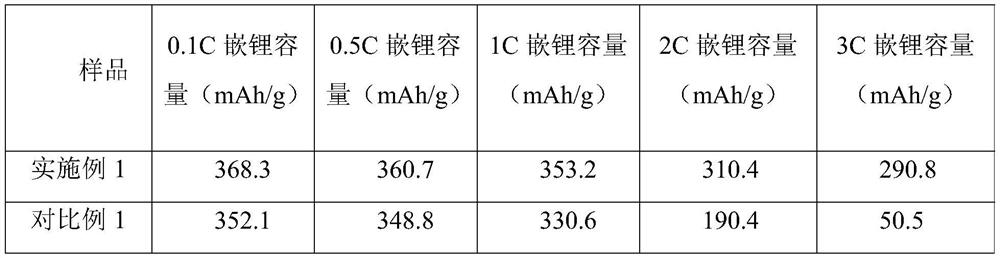

Examples

Embodiment 1

[0020] This embodiment provides a method for preparing a porous nitrogen-doped carbon-coated graphite material, which at least includes the following steps:

[0021] Step 1, first weigh 150g melamine, 200g citric acid as organic acid, 0.5g modified graphene powder, 1000g ethanol as solvent, mix well on a small stirrer, then weigh 1000g D50=15 μm artificial graphite, pour Put it into a mixing tank, stir evenly, transfer it to an oven at 80°C for drying. Wherein, the modified graphene is graphene grafted with -OOH, -OH functional groups.

[0022] Step 2: Grind after drying, pass through a 325-mesh sieve, and put the powder into the cavity of the rotary furnace. The rotating speed of the rotary furnace is 800rpm, and N2 protection is introduced, heated to 300°C, and kept for 3 hours. The amino groups of melamine and The organic acid and the carboxyl group in the modified graphene react to form functional structural components containing C-N bonds, and the carboxyl group of the o...

Embodiment 2

[0025] This embodiment provides a method for preparing a porous nitrogen-doped carbon-coated graphite material, which at least includes the following steps:

[0026] Step 1, first take by weighing 250g melamine, 250g citric acid as organic acid, 8g modified graphene powder, 2000g ethanol as solvent, mix on small stirrer, then take by weighing 1000g D50=6 μ m natural graphite, pour into In a stirring tank, after stirring evenly, transfer to a 100°C oven for drying. Among them, the modified graphene is graphene grafted with -OOH, -OH functional groups

[0027] Step 2: Grind after drying, pass through a 325-mesh sieve, and put the powder into the cavity of the rotary furnace. React with organic acids and carboxyl groups in modified graphene to form functional structural components containing C-N bonds, carboxyl groups of organic acids and hydroxyl groups in modified graphene to generate esters, and then continue to heat up to 900°C for carbonization for 5 hours. After the sampl...

Embodiment 3

[0030] This embodiment provides a method for preparing a porous nitrogen-doped carbon-coated graphite material, which at least includes the following steps:

[0031] Step 1, first weigh 200g melamine, 180g stearic acid as organic acid, 4g modified graphene powder, 1500g isopropanol as solvent, mix well on a small stirrer, and then weigh 1000g D50=18 μm natural graphite , poured into a mixing tank, stirred evenly, transferred to a 150°C oven for drying. Wherein, the modified graphene is graphene grafted with -OOH, -OH functional groups.

[0032] Step 2: Grind after drying, pass through a 325-mesh sieve, and put the powder into the cavity of the rotary furnace. React with organic acid and carboxyl group in modified graphene to generate functional structural components containing C-N bonds, carboxyl group of organic acid and hydroxyl group in modified graphene to generate esters. Then continue to heat up to 700°C for carbonization for 6h. After the sample is cooled, the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com