Preparation method for moisturizing lipstick containing shikonin liposomes

A production method and technology of shikonin lipid, which are applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as difficulty in adding natural pigments, high cost of extraction of natural pigments, and affecting coloring effects, etc., to achieve increased film strength, Improve the emulsification effect, the effect of not easy to break the emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

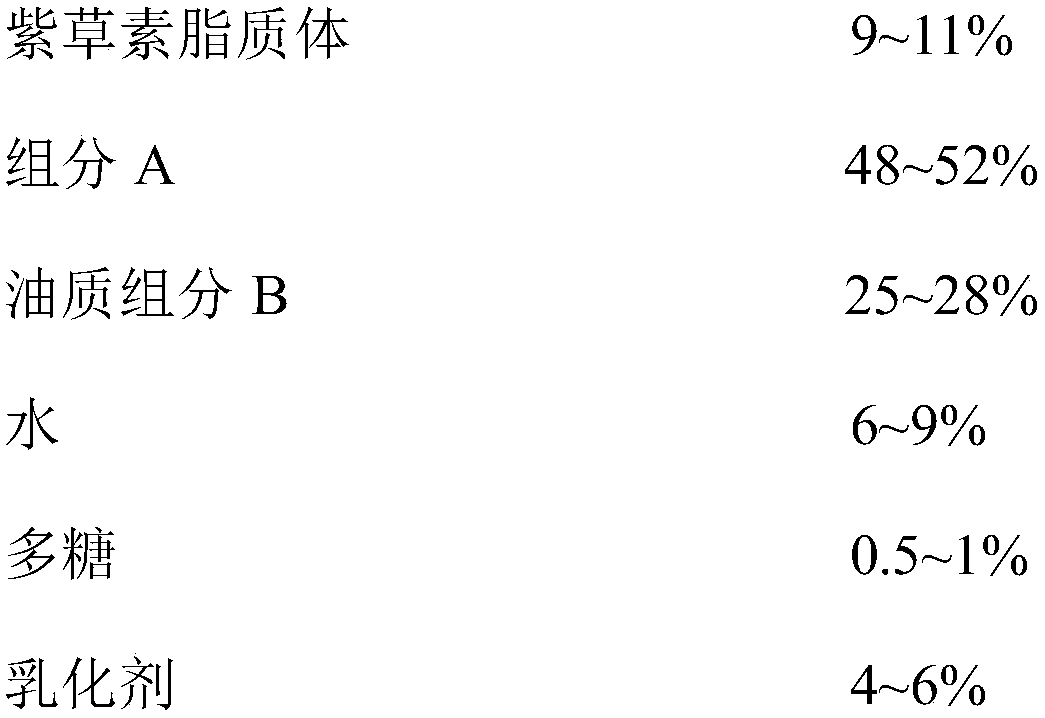

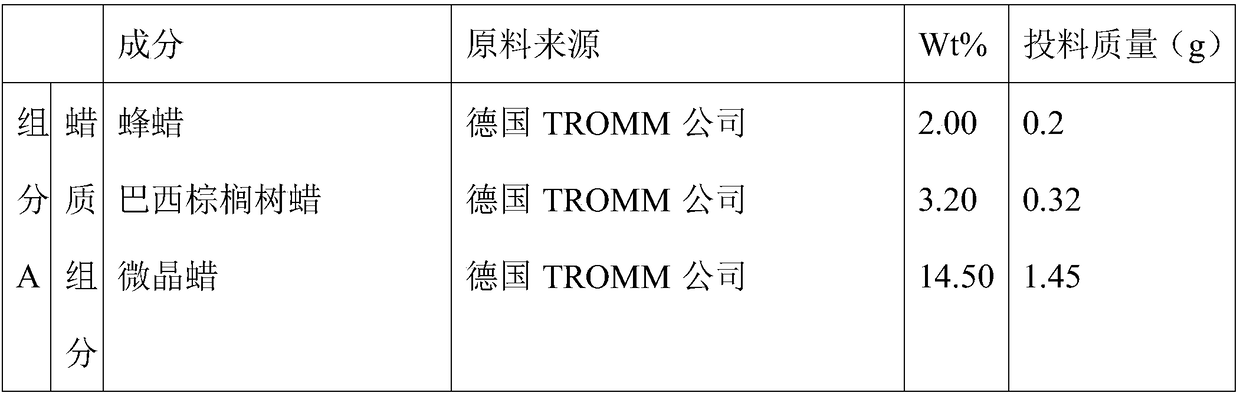

[0046] Table 1.1

[0047]

[0048]

[0049] The steps for preparing the above-mentioned products are as follows:

[0050] (1) Preparation of shikonin liposomes: Weigh 2g of lecithin and 0.4g of cholesterol in a round bottom flask, add 500mL of petroleum ether, stir to dissolve, then add 0.4g of shikonin, and rotate under reduced pressure at 40°C Recover the organic solvent, form a uniform purple-red lipid film in the round bottom flask, then add 200mL PBS buffer solution (pH=7.4), stir and elute the lipid film for 1 hour, sonicate in a water bath at 25°C for 5 minutes, filter with a 0.45 μm microporous membrane, Stand still for 10 minutes, repeat ultrasonic and filter membrane filtration under the same conditions, use a spray dryer to spray dry the obtained product at an inlet temperature of 110°C, and obtain 1.2 g of shikonin liposome;

[0051] (2) Beeswax, carnauba wax, microcrystalline wax, jojoba oil, avocado oil, squalane, oleyl erucate, polyhydroxystearic acid, ce...

Embodiment 2

[0076] Table 2.1

[0077]

[0078]

[0079] The steps for preparing the above-mentioned products are as follows:

[0080] (1) Preparation of shikonin liposomes: Weigh 1.5g lecithin and 0.25g cholesterol in a round bottom flask, add 300mL petroleum ether, stir to dissolve, then add 0.5g shikonin, spin under reduced pressure at 50°C Evaporate and recover the organic solvent, and form a uniform purple-red lipid film in the round bottom flask, then add 180mL 0.9% NaCl solution, stir and elute the lipid film for 2 hours, ultrasonicate in a water bath at 26°C for 10 minutes, filter with a 0.45 μm microporous membrane, and stand for 5 minutes , repeated ultrasonication and filter membrane filtration under the same conditions, using a spray dryer to spray dry the obtained product at an inlet temperature of 130° C. to obtain 1 g of shikonin liposome;

[0081] (2) Carnauba wax, microcrystalline wax, candelilla wax, avocado oil, macadamia nut oil, polyhydroxystearic acid, cetyl et...

Embodiment 3

[0102] chart 3.1

[0103]

[0104]

[0105]

[0106] The steps for preparing the above-mentioned products are as follows:

[0107] (1) Preparation of shikonin liposomes: Weigh 2.1g lecithin and 0.4g cholesterol in a round bottom flask, add 450mL petroleum ether, stir to dissolve, then add 0.3g shikonin, spin under reduced pressure at 45°C Evaporate and recover the organic solvent, and form a uniform purple-red lipid film in the round bottom flask, then add 200mL 0.9% NaCl solution, stir and elute the lipid film for 2 hours, ultrasonicate in a water bath at 28°C for 8 minutes, filter with a 0.45μm microporous membrane, and let stand for 10 minutes , repeated ultrasonication and membrane filtration under the same conditions, using a spray dryer to spray dry the obtained product at an inlet temperature of 120°C to obtain 1.5 g of shikonin liposomes;

[0108] (2) Beeswax, microcrystalline wax, candelilla wax, jojoba oil, macadamia nut oil, polyhydroxystearic acid, octyld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com