Preparation method and application of core-shell catalyst which adopts transition metal salt as core and nano-molecular sieve as shell

A technology of nano-molecular sieves and transition metal salts, which is applied in the direction of molecular sieve catalysts, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems such as difficult separation, achieve easy-to-obtain raw materials, simple preparation process, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

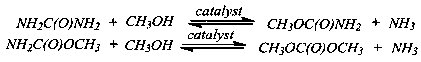

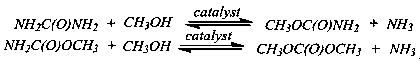

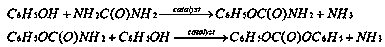

Method used

Image

Examples

Embodiment 1

[0032] Example 1: In this example, the core-shell catalyst with transition metal salt as the core silicalite-1 molecular sieve as the shell is ZnCl 2 @silicallite-1 core-shell catalyst;

[0033] A method for preparing a core-shell catalyst with a transition metal salt as the core silicalite-1 molecular sieve as the shell, and the specific steps are as follows:

[0034] (1) Preparation of monodisperse spherical zinc oxide powder;

[0035] (2) The spherical zinc oxide powder of step (1) is immersed in the negative polyelectrolyte solution for 10 minutes, and centrifuged to obtain filtrate I and filter residue I; the solid-to-liquid ratio of the spherical zinc oxide powder to the negative polyelectrolyte solution is g: mL is 0.1:50; the mass percentage concentration of the negative polyelectrolyte in the negative polyelectrolyte solution is 0.3%, and the negative polyelectrolyte is poly(p-styrenesulfonic acid) PPS;

[0036] (3) The filter residue I of step (2) is immersed in the positive...

Embodiment 2

[0045] Example 2: In this example, the core-shell catalyst with transition metal salt as the core silicalite-1 molecular sieve as the shell is CuBr 2 @silicallite-1 core-shell catalyst;

[0046] A method for preparing a core-shell catalyst with a transition metal salt as the core silicalite-1 molecular sieve as the shell, and the specific steps are as follows:

[0047] (1) Preparation of monodisperse spherical copper oxide powder;

[0048] (2) The spherical copper oxide powder of step (1) was immersed in the negative polyelectrolyte solution for 15 minutes, and centrifuged to obtain filtrate I and filter residue I; the solid-to-liquid ratio of the spherical copper oxide powder to the negative polyelectrolyte solution g: mL is 1:60; the mass percentage concentration of the negative polyelectrolyte in the negative polyelectrolyte solution is 5.0%, and the negative polyelectrolyte is poly(p-styrene sulfonic acid) PPS;

[0049] (3) Immerse the filter residue I of step (2) in the positive ...

Embodiment 3

[0058] Example 3: In this example, the core-shell catalyst with transition metal salt as the core silicalite-1 molecular sieve as the shell is Ni(NO 3 ) 2 @silicallite-1 core-shell catalyst;

[0059] A method for preparing a core-shell catalyst with a transition metal salt as the core silicalite-1 molecular sieve as the shell, and the specific steps are as follows:

[0060] (1) Preparation of monodisperse spherical nickel hydroxide powder;

[0061] (2) The spherical nickel hydroxide powder of step (1) is immersed in the positive polyelectrolyte solution for 20 minutes, and centrifuged to obtain filtrate I and filter residue I; the solid-to-liquid ratio of the spherical nickel oxide powder to the negative polyelectrolyte solution is g :mL is 0.5:55; the mass percentage concentration of the negative polyelectrolyte in the negative polyelectrolyte solution is 2.45%, and the negative polyelectrolyte is poly(p-styrene sulfonic acid) PPS;

[0062] (3) The filter residue I of step (2) is imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com