Method for removing iron and regenerating tungsten powder from high-iron reduced tungsten powder

A technology of tungsten powder and high-speed iron, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems that affect the processing performance of tungsten products, are not suitable for the high activity characteristics of tungsten powder, and have no economical and effective methods, so as to ensure the dissolution and iron removal Effect, stable control of product quality, and the effect of realizing comprehensive utilization of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

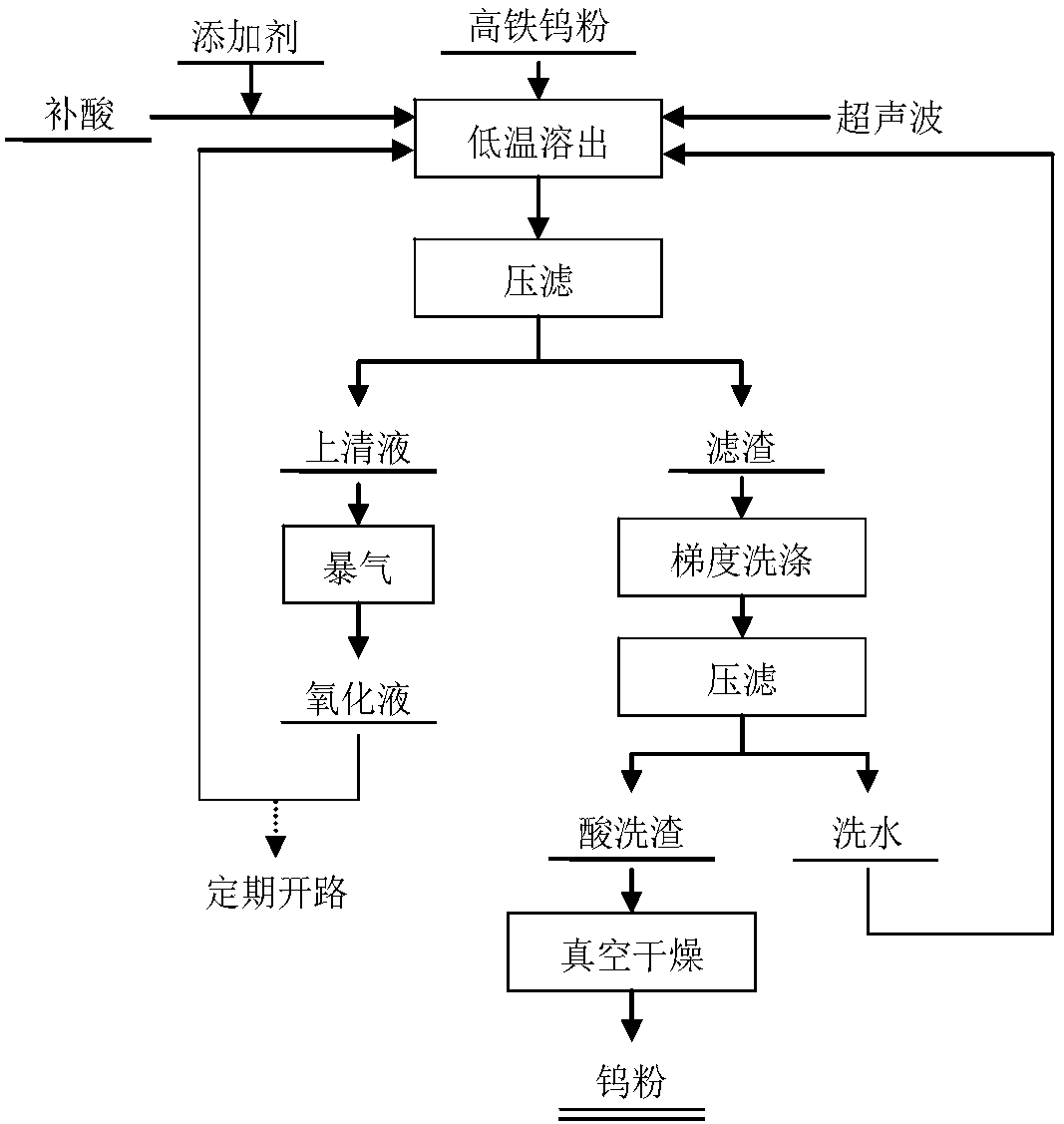

[0050] This embodiment is a method for removing iron and regenerating tungsten powder from high-iron reduced tungsten powder. The process flow chart is as attached figure 2 shown.

[0051] The composition of the tungsten powder used as the test raw material is: Fe 1.36%, Si 190ppm, K 120ppm, Al 40ppm, Na110ppm; the composition of the acidic high iron eluate is: Fe T 10.47g / L, acidity 0.5g / L.

[0052] The specific steps of this embodiment are as follows:

[0053] S1. Low-temperature dissolution: Weigh 100g of the tungsten powder of the above ingredients, add 1000mL of the above-mentioned high-iron dissolution solution according to the liquid-solid ratio of 10:1, add 2g of hydrogen peroxide, and ultrasonic intensity of 50kHz, react at 10°C for 2 hours, and filter to separate the dissolution solution and insoluble Tungsten powder, 988mL eluate and 110.0g insoluble tungsten slag were obtained. Analysis of Fe in solution T It was 11.96g / L, and the dissolution rate of iron was...

Embodiment 2

[0058] This embodiment is a method for removing iron and regenerating tungsten powder from high-iron reduced tungsten powder. The process flow chart is as attached figure 2 shown.

[0059] The tungsten powder as test raw material is with embodiment 1; The composition of acid high iron eluate is: Fe T 20.31g / L, acidity 0.6g / L.

[0060] The specific steps of this embodiment are as follows:

[0061] S1. Low-temperature dissolution: Weigh 100g of tungsten powder of the above ingredients, add 1500mL of the above-mentioned high-iron dissolution solution according to the liquid-solid ratio of 15:1, add 3g of ferric chloride, and ultrasonic intensity of 100kHz, react at 3°C for 3 hours, and filter to separate and dissolve solution and insoluble tungsten powder to obtain 1488mL of eluate and 109.07g of insoluble tungsten slag. Analysis of Fe in solution T It was 21.21g / L, and the dissolution rate of iron was calculated to be 99.36%;

[0062] S2. Gas oxidation: Take 1400mL of t...

Embodiment 3

[0066] This embodiment is a method for removing iron and regenerating tungsten powder from high-iron reduced tungsten powder. The process flow chart is as attached figure 2 shown.

[0067] The tungsten powder as test raw material is the same as in Example 1; the acidic high-iron eluate is taken from the washing water of Example 2, 1100mL of the liquid after the storm, and the acidic adjustment composition is: Fe T 8.15g / L, acidity 0.8g / L eluate, the remaining 203mL after gassing is treated as an open circuit.

[0068] The specific steps of this embodiment are as follows:

[0069] S1. Low-temperature dissolution: Weigh 100g of tungsten powder of the above ingredients, add 700mL of the above-mentioned high-iron dissolution solution according to the liquid-solid ratio of 7:1, add 3g of concentrated hypochlorous acid, and ultrasonic intensity of 40kHz, react at 5°C for 3 hours, and filter to separate and dissolve solution and insoluble tungsten powder to obtain 691mL of eluate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com