Method for preparing automobile engine cooling liquid

A technology of automobile engine and coolant, which is applied in the field of coolant, can solve problems such as corrosion, achieve the effects of delaying the corrosion process, obvious anti-corrosion effect, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

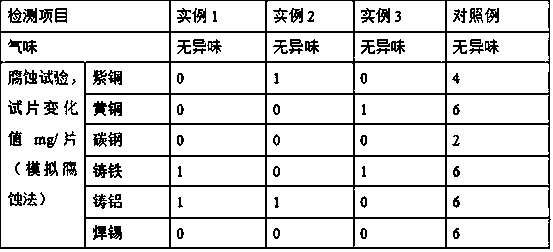

Examples

example 1

[0026] Mix Span80 and OP-10 uniformly at a mass ratio of 8:1 to obtain a composite emulsifier, add the composite emulsifier and ammonia water to cyclohexane at a mass ratio of 1:0.2:12, and stir magnetically for 1 hour to obtain emulsion A, press Mix graphene and emulsion A at a mass ratio of 1:5, and ultrasonically disperse for 20 minutes to obtain a dispersion; mix benzoic acid, triethylenetetramine and xylene uniformly at a mass ratio of 1:1.2:2, and stir at a temperature of 150°C React for 2 hours, continue to slowly heat up to 220°C, stir and react for 2h to obtain an imidazoline intermediate, then cool the system to 90°C and add isopropanol and water with a volume ratio of 2:1 as solvent, add a quaternizing agent to react for 4 hours, To obtain the complex, add the complex to deionized water according to the mass ratio of 0.1:10, and ultrasonicate for 10 minutes to obtain the mixed solution; under mechanical stirring, slowly add the mixed solution to the dispersion liquid...

example 2

[0028]Mix Span80 and OP-10 uniformly at a mass ratio of 8:1 to obtain a composite emulsifier, add the composite emulsifier and ammonia water to cyclohexane at a mass ratio of 1:0.2:12, and stir magnetically for 1 hour to obtain emulsion A, press Mix graphene and emulsion A at a mass ratio of 1:5, ultrasonically disperse for 25 minutes to obtain a dispersion; mix benzoic acid, triethylenetetramine and xylene uniformly at a mass ratio of 1:1.2:2, and stir at a temperature of 155°C React for 2 hours, continue to slowly heat up to 235°C, stir and react for 2h to obtain an imidazoline intermediate, then cool the system to 95°C and add isopropanol and water with a volume ratio of 2:1 as solvent, add a quaternizing agent to react for 5 hours, To obtain the complex, add the complex to deionized water according to the mass ratio of 0.1:10, and ultrasonicate for 15 minutes to obtain the mixed solution; under mechanical stirring, the mixed solution is slowly added to the dispersion accord...

example 3

[0030] Mix Span80 and OP-10 uniformly at a mass ratio of 8:1 to obtain a composite emulsifier, add the composite emulsifier and ammonia water to cyclohexane at a mass ratio of 1:0.2:12, and stir magnetically for 2 hours to obtain emulsion A, press Mix graphene and emulsion A at a mass ratio of 1:5, and ultrasonically disperse for 30 minutes to obtain a dispersion; mix benzoic acid, triethylenetetramine and xylene uniformly at a mass ratio of 1:1.2:2, and stir at a temperature of 160°C React for 3 hours, continue to slowly heat up to 250°C, stir and react for 3h to obtain an imidazoline intermediate, then cool the system down to 100°C and add isopropanol and water with a volume ratio of 2:1 as solvent, add a quaternizing agent to react for 6h, To obtain the complex, add the complex to deionized water according to the mass ratio of 0.1:10, and ultrasonicate for 20 minutes to obtain the mixed solution; under mechanical stirring, slowly add the mixed solution to the dispersion liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com