Method for producing biological butanol and bioethanol by using corn straw as main raw material

A technology of corn stalks, the main raw material, applied in the field of fermentation, which can solve the problems of difficulty in straw utilization, low efficiency, and high cost of bio-fermentation alcohol production, and achieve the effects of good wall breaking effect, cost reduction, and improvement of fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for producing bio-butanol and bio-ethanol by using corn stalks as the main raw material for fermentation comprises the following steps:

[0038] First crush the corn stalks to less than 5cm, then put them under the conditions of pressure 1.5MPa and residence time 15min for steam explosion pretreatment, and then carry out blasting; pass the steam explosion treated corn stalks through a 50-mesh sieve, collect the sieve, Then add the undersize to 2 times the weight of water, heat to 60°C, stir at 100rpm for 90min under heat preservation conditions, then heat to 121°C, keep heat for 10min, and naturally cool to room temperature to obtain a culture solution;

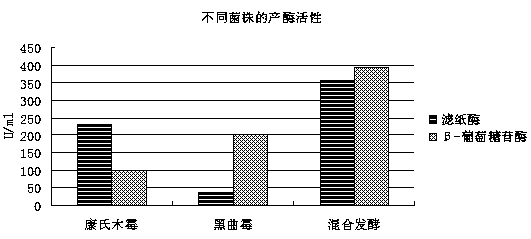

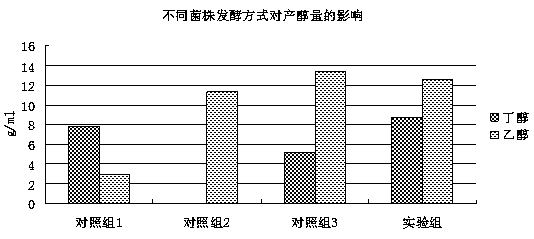

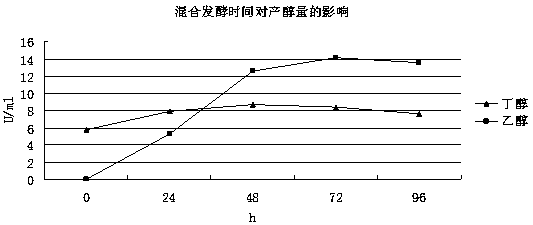

[0039] Trichoderma konii seed liquid (density 1 × 108 cfu / mL) and Aspergillus niger seed solution (density 1×10 8 cfu / mL) mixed according to the volume ratio of 2:1, and then inoculated into the culture medium according to the inoculum amount of 6-8%, and cultivated for 96 hours. During the cultivation, the ...

Embodiment 2

[0042] The method for producing bio-butanol and bio-ethanol by using corn stalks as the main raw material for fermentation comprises the following steps:

[0043] Firstly crush the corn stalks to less than 5cm, then place them under the conditions of pressure 2MPa and residence time 10min for steam explosion pretreatment, and then carry out blasting; pass the steam explosion treated corn stalks through a 50-mesh sieve, collect the sieved material, and then Add the undersieve to 1.5 times the weight of water, heat to 60°C, stir at 100rpm for 90min under heat preservation conditions, then heat to 121°C, keep heat for 10min, and naturally cool to room temperature to obtain a culture solution;

[0044] Trichoderma konii seed liquid (density 1 × 10 8 cfu / mL) and Aspergillus niger seed solution (density 1×10 8 cfu / mL) mixed according to the volume ratio of 3:2, and then inoculated into the culture medium according to the inoculum amount of 6-8%, and cultivated for 96 hours. During ...

Embodiment 3

[0047] The changes in the main components of corn stalks caused by blasting are shown in Table 1:

[0048] Table 1

[0049] index

[0050] Conclusion: Blasting caused the cell wall of straw to be destroyed, and some hemicellulose and cellulose were degraded and dissolved, which was beneficial to the subsequent enzymatic hydrolysis of cellulose by cellulase; the crystallinity and polymerization degree of cellulose decreased during the blasting pretreatment process, and hemicellulose passed It is degraded into xylose by hydrolysis and can be used as a carbon source for the strain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com