Oil-proof packaging paper

A wrapping paper and oil-proof technology, which is applied in wrapping paper, wrapping paper, packaging, etc., can solve the problems of oil-proof wrapping paper with insignificant oil-proof effect and toxic substances, etc., achieve superior oil resistance, weaken lipophilicity, and reduce porosity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

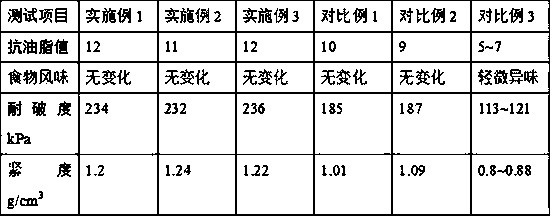

Examples

preparation example Construction

[0026] The preparation method of composite oil-repellent component comprises the following steps:

[0027] S1. Preparation of composite modified starch: take cornstarch, add 0.1mol / L sodium hydroxide solution, ferric thiocyanate, and water at a mass ratio of 3:1:1:7~9, at 80~85°C, Mix and stir at 90~110r / min to get mixed solution A, add solvent A with 10~15% of mixed solution A mass, mix and stir for 20~30min, let stand for 22~24h, get modified starch, take modified starch, add Water with 1.5~2 times the mass of modified starch is stirred and mixed at 55~60°C at 230~250r / min to obtain the mixed solution B.

[0028] S2. Add fatty alcohol polyoxyethylene ether sodium sulfate of 4~8% of the mass of the mixed solution B, and stir for 20~30min with nitrogen gas, then add 2~5% of the initiator of the mass of the mixed solution B, 7~12% of the Solvent B and 3-8% hexafluorobutyl methacrylate, mixed and stirred for 4-5 hours, then added 7-12% hydroquinone of the mass of the mixed solu...

Embodiment 1

[0036] Silk fibroin powder: purchased from Silk Biotechnology Co., Ltd.

[0037]Pulp: purchased from Shandong Tranlin Paper Co., Ltd.

[0038] Solvent A: Take epichlorohydrin, trimethylamine hydrochloride, and water and mix them in a mass ratio of 1:1:3 to obtain solvent A.

[0039] Solvent B: Take calcium chloride, ethanol, and water and mix them in a mass ratio of 2:1:4 to obtain solvent B.

[0040] Initiator: Potassium persulfate and sodium bisulfite are mixed in a molar ratio of 1:0.45 to obtain the initiator.

[0041] The preparation method of composite oil-repellent component comprises the following steps:

[0042] S1. Preparation of composite modified starch: Take cornstarch, add 0.1mol / L sodium hydroxide solution, ferric thiocyanate, and water at a mass ratio of 3:1:1:7, and heat it at 80°C at 90r / min Mix and stir to obtain mixed solution A, add solvent A with 10% of the mass of mixed solution A, mix and stir for 20 minutes, and let it stand for 22 hours to obtain m...

Embodiment 2

[0051] Silk fibroin powder: purchased from Silk Biotechnology Co., Ltd.

[0052] Pulp: purchased from Shandong Tranlin Paper Co., Ltd.

[0053] Solvent A: Take epichlorohydrin, trimethylamine hydrochloride, and water and mix them in a mass ratio of 1:2:3 to obtain solvent A.

[0054] Solvent B: Take calcium chloride, ethanol, and water and mix them in a mass ratio of 2:1:5 to obtain solvent B.

[0055] Initiator: Potassium persulfate and sodium bisulfite are mixed in a molar ratio of 1:0.75 to obtain the initiator.

[0056] The preparation method of composite oil-repellent component comprises the following steps:

[0057] S1. Preparation of composite modified starch: Take cornstarch, add 0.1mol / L sodium hydroxide solution, ferric thiocyanate, and water at a mass ratio of 3:1:1:9, and heat it at 85°C at 110r / min Mix and stir to obtain mixed solution A, add solvent A with 15% of the mass of mixed solution A, mix and stir for 30 minutes, and let it stand for 24 hours to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com