Preparation method of ion-doped cellulose gas separation membrane and cellulose gas separation membrane

A gas separation membrane, cellulose technology, applied in separation methods, dispersed particle separation, semi-permeable membrane separation and other directions, can solve the problem of mechanical properties and acid, alkali and organic solvent resistance decline, polymerization degree, crystallinity decline, limited application Scope and other issues, to achieve the effect of good reusability, uniform distribution and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

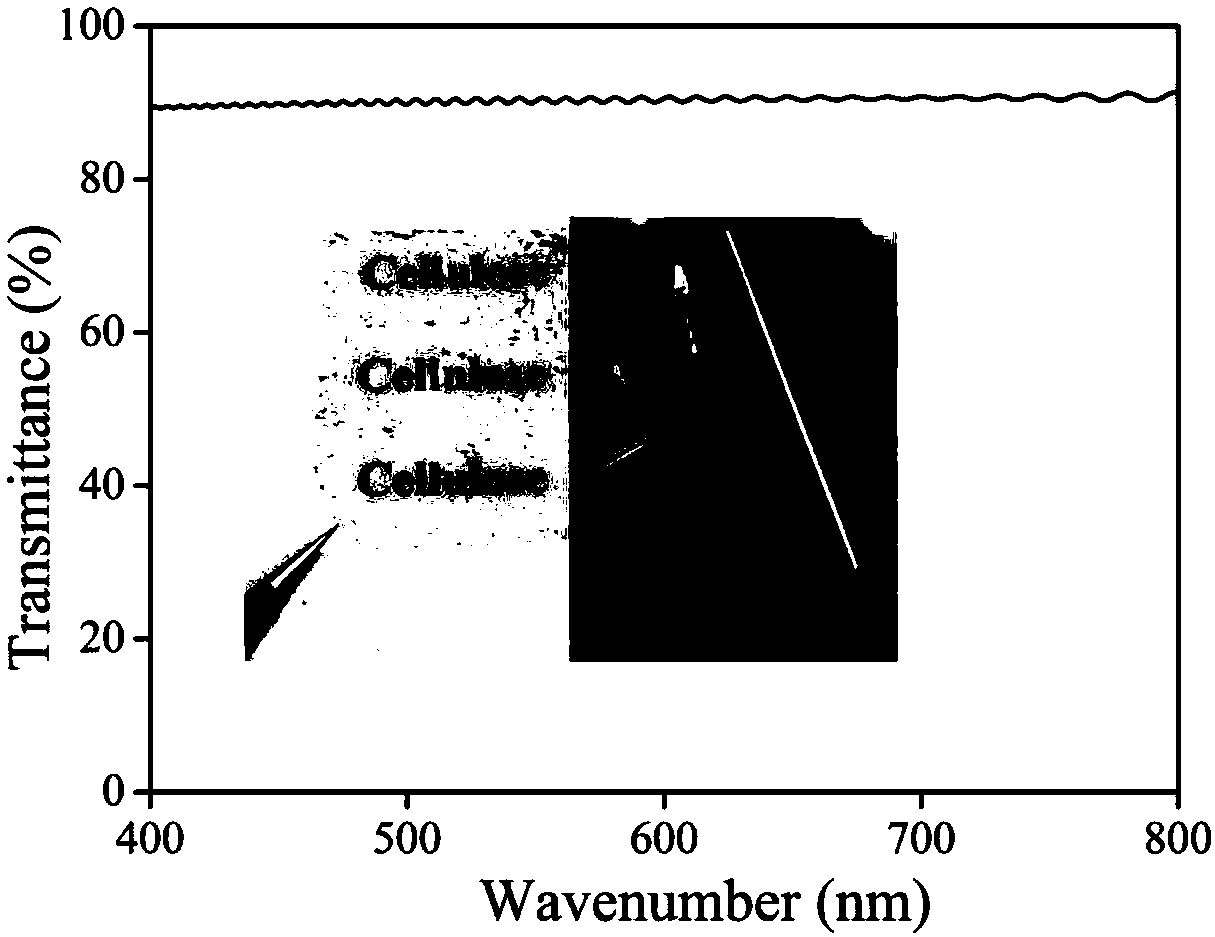

[0031] Weigh 9.87g ZnCl 2 and 0.48g CaCl 2 Put it into a beaker, add deionized water to 15.00g, configure it as a mixed salt solution, add 0.25g of cotton linters (the degree of polymerization is in the range of 200-2000), heat to 80°C, and stir for 2 hours to obtain a uniform cellulose Solution, after vacuum degassing, scrape the film on the substrate to form a solution layer of 0.1 mm, soak it in an isopropanol coagulation bath for 10 minutes after vacuum degassing, shape it with a jig, dry it in the air, and store it in an airtight container to obtain a transparent Regenerated cellulose gas separation membrane. Its visible spectrum and physical photos are as follows: figure 1 shown, from figure 1 It can be seen that the high transmittance in the visible light region indicates its optical transparency, and the foldability indicates its good flexibility. The metal ion content and gas permeability of the regenerated cellulose membrane are listed in Table 1.

Embodiment 2

[0035] Weigh 15.00g ZnCl 2 and 1.00g CoCl 2Put it into a beaker, add deionized water to 20.00g, configure a mixed salt solution, add 0.61g of absorbent cotton (the degree of polymerization is in the range of 200-2000), heat at 70°C, and stir for 1 hour to obtain a uniform cellulose solution , after vacuum degassing, scrape the film on the substrate to form a solution layer of 0.2 mm, soak in methanol coagulation bath for 20 minutes after vacuum degassing, set the shape with the fixture, dry in the air, store in a closed container, and obtain transparent regenerated cellulose Membrane, its surface and cross-section photographs are shown in figure 2 shown, from figure 2 It can be seen that the surface and cross section of the product of the present invention are smooth and smooth without defects. The metal ion content and gas permeability of the regenerated cellulose membrane are listed in Table 1.

Embodiment 3

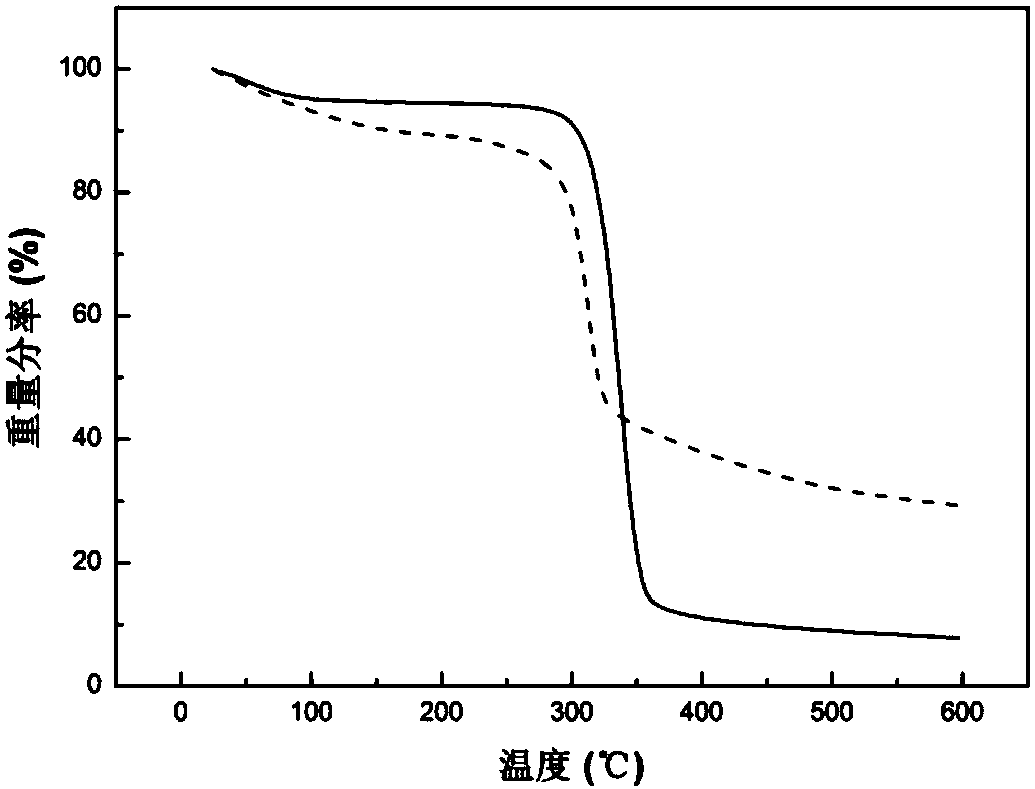

[0039] Weigh 6.88g ZnCl 2 and 0.70g ZrOCl 2 Put it into a beaker, add deionized water to 12.0g, configure it as a mixed salt solution, add 0.95g of microcrystalline cellulose (the degree of polymerization is in the range of 200-2000), heat at 55°C, and stir for 20 minutes to obtain a uniform Cellulose solution, after degassing, scrape the film on the substrate to form a solution layer of 0.3mm, soak in an acetone coagulation bath for 30 minutes after vacuum degassing, shape it with a jig, dry it in the air, and store it in an airtight container to obtain a transparent regenerated fiber The plain film, its metal ion content and gas permeability are listed in Table 1. image 3 It is a comparison chart of thermogravimetric curves of the prepared regenerated cellulose film and cellulose raw material. The solid line is the cellulose raw material, the dotted line is the regenerated cellulose film, from image 3 It can be seen that two-step decomposition: from about 50 °C to 200 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com