Preparation method of carbon aerogel thermal insulation material

A thermal insulation material, carbon aerogel technology, applied in the field of carbon aerogel thermal insulation materials and its preparation, can solve the problems of high carbon aerogel density, short process cycle, large shrinkage, etc., to increase the degree of crosslinking and uniformity, accelerate the gel polymerization reaction, enhance the effect of cross-linking degree and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

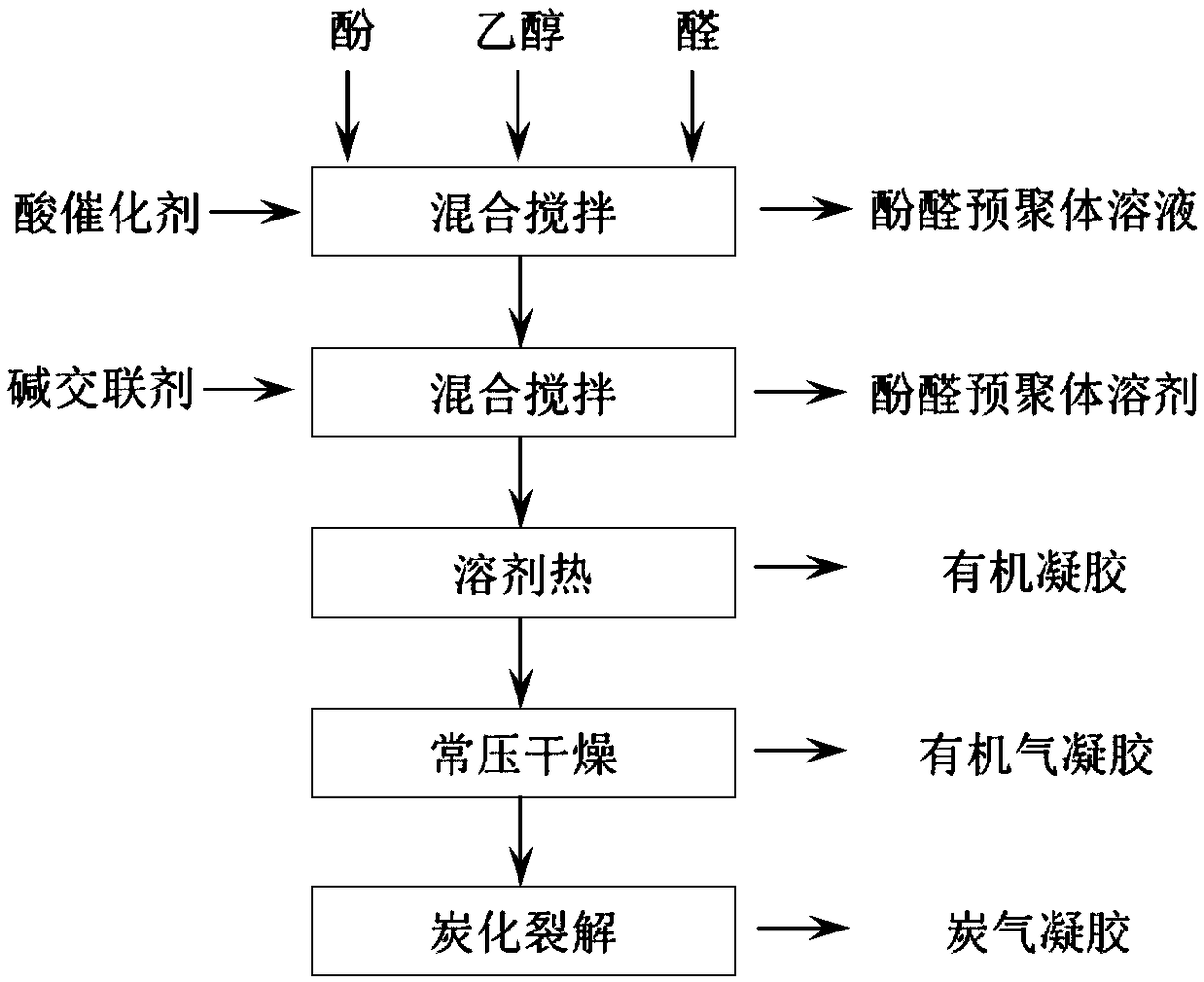

[0032] A kind of preparation method of carbon airgel thermal insulation material, process flow chart is as follows figure 1 shown, including the following steps:

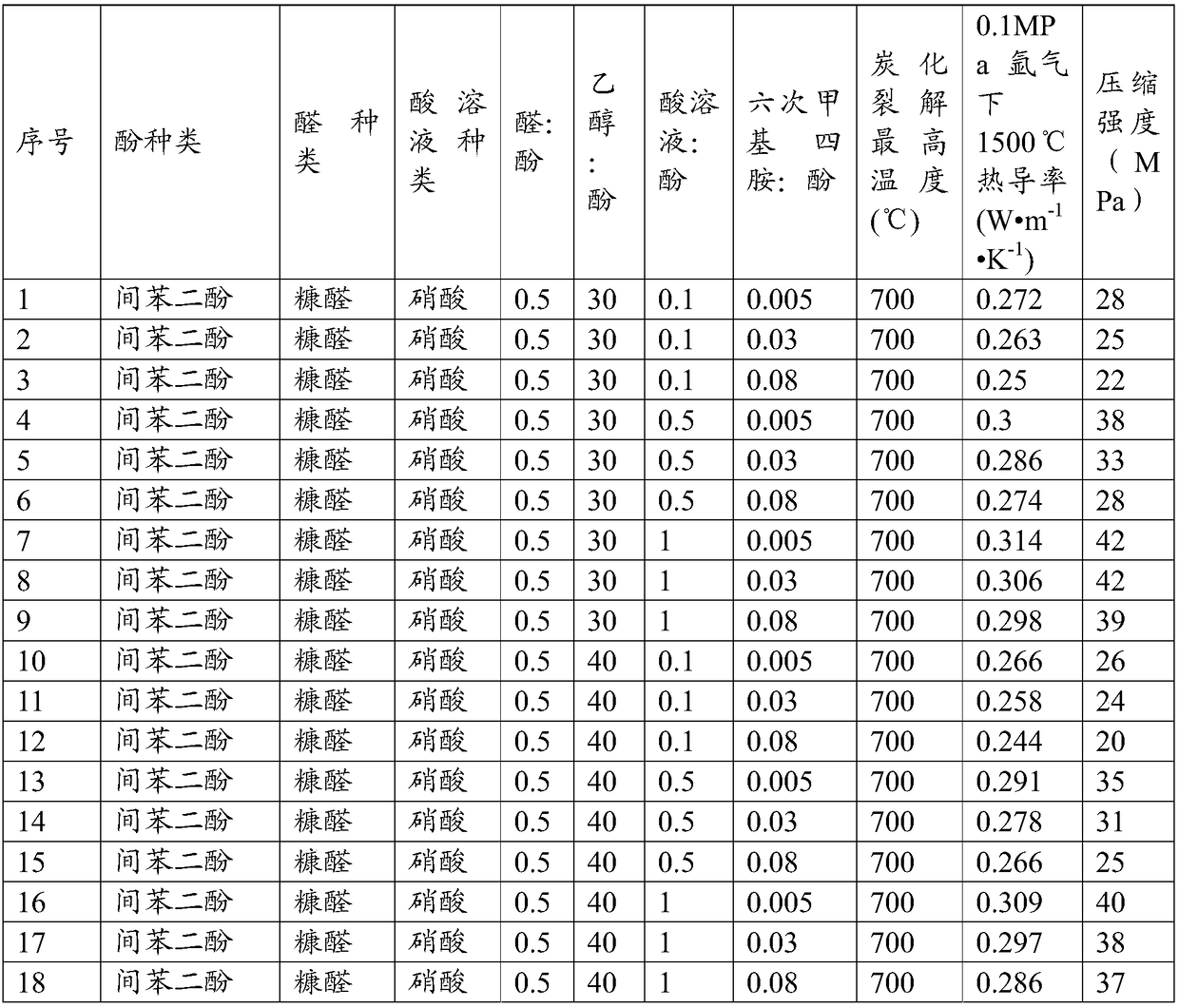

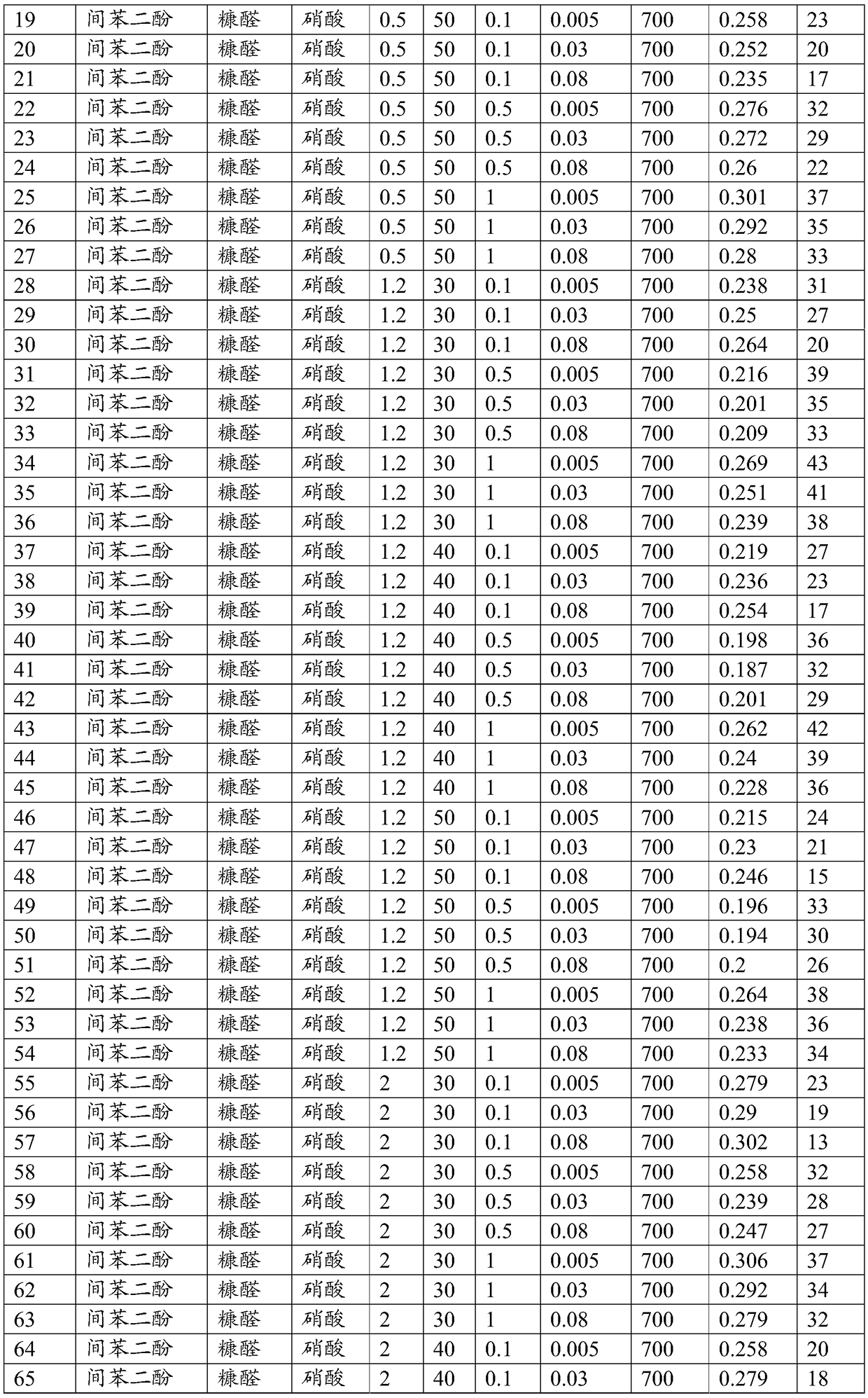

[0033] (1) The phenolic prepolymer sol was prepared by an acid-base two-step method: resorcinol and furfural were used as carbon precursors, nitric acid with a concentration of 0.5mol / L was used as an acid catalyst, and hexamethylenetetramine was used as a base Non-toxic crosslinking agent, using ethanol as solvent to configure phenolic prepolymer sol, the specific process is: first mix resorcinol, furfural, ethanol and nitric acid at room temperature and stir for 100 minutes, then add hexamethylenetetramine, continue stirring until uniform , obtain phenolic prepolymer sol, wherein the molar proportion of raw material is aldehyde organic monomer: phenolic organic monomer=0.5, ethanol: phenolic organic monomer=30, acid solution: phenolic organic monomer=0.1, hexamethylene Tetramine: phenol organic monomer=0.005;

...

Embodiment 2~1944

[0039] A method for preparing a carbon airgel thermal insulation material, comprising the following steps: the first step, adopting an acid-base two-step method to prepare a phenolic prepolymer sol: first, phenolic organic monomers and aldehyde organic monomers as carbon precursors 1. The acid as the acid catalyst and the ethanol as the solvent are mixed and stirred at normal temperature, then the basic crosslinking agent hexamethylenetetramine is added, and the stirring is continued until uniform to obtain the phenolic prepolymer sol;

[0040] The second step is to prepare organic gel by solvothermal process: put the phenolic prepolymer sol obtained in the first step into the autoclave and seal it, and pre-fill nitrogen or argon protective gas to provide a high-pressure environment to prevent the heating process of the solvothermal process The medium solvent is excessively volatilized, and after the pressure of nitrogen or argon protective gas reaches the predetermined pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com