High strength environment-friendly plastic material and preparation method thereof

A plastic material and high-strength technology, which is applied in the field of high-strength environmentally friendly plastic materials and their preparation, can solve problems such as stress cracking, wear resistance, oil resistance and oxidation resistance, poor flame retardancy, and low impact resistance. Improved toughness, low price, safe and environmentally friendly use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

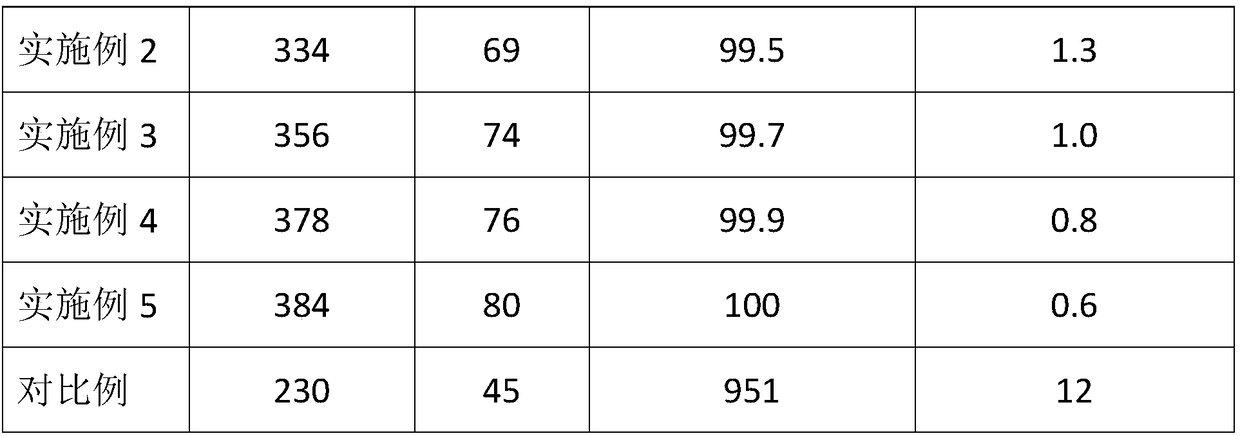

Examples

Embodiment 1

[0026] A high-strength environment-friendly plastic material, made of the following components by weight: 100 parts of chitosan poly-2,5-furandicarboxylate 1,3-adamantanediol ester, 5 parts of diatomaceous earth, 1 part of silane coupling agent KH550, 1 part of acrylate, 1 part of phenyl salicylate.

[0027] The preparation method of the terminal chitosan poly 2,5-furandicarboxylic acid 1,3-adamantanediol ester comprises the following steps: 100g of 2,5-furandicarboxylic acid, 1,3-adamantanediol Add 100g of alcohol to 500g of dimethyl sulfoxide, then add 30g of dicyclohexylcarbodiimide and 50g of 4-dimethylaminopyridine, stir for 0.5 hours in an ice-water bath under a nitrogen atmosphere, and then stir at 60°C After reacting for 20 hours, add 20 g of chitosan, continue to stir and react for 2 hours, after the reaction finishes, precipitate in water, and wash the product 5 times with dichloromethane, then place it in a vacuum drying oven at 75°C and bake for 18 hours to obtain ...

Embodiment 2

[0032] A high-strength environment-friendly plastic material, made of the following components in parts by weight: 100 parts of chitosan poly-2,5-furandicarboxylate 1,3-adamantanediol ester, 7 parts of diatomaceous earth, 2 parts of silane coupling agent KH560, 2 parts of methyl methacrylate-butadiene-styrene copolymer, 2 parts of 2,4-dihydroxybenzophenone.

[0033] The preparation method of the terminal chitosan poly 2,5-furandicarboxylic acid 1,3-adamantanediol ester comprises the following steps: 100g of 2,5-furandicarboxylic acid, 1,3-adamantanediol After 102 g of alcohol was added to 750 g of N,N-dimethylformamide, 35 g of dicyclohexylcarbodiimide and 50 g of 4-dimethylaminopyridine were added thereto, and stirred for 0.7 hours in an ice-water bath under a helium atmosphere. Then stir and react at 65°C for 21.5 hours, then add 25g of chitosan, continue to stir and react for 2.3 hours, after the reaction, it will settle out in water, wash the product 6 times with dichlorom...

Embodiment 3

[0038] A high-strength environment-friendly plastic material, made of the following components in parts by weight: 100 parts of chitosan poly-2,5-furandicarboxylate 1,3-adamantanediol ester, 8 parts of diatomaceous earth, 2 parts of silane coupling agent KH570, 3 parts of acrylate, 2 parts of 2-hydroxy-4-methoxybenzophenone.

[0039] The preparation method of the terminal chitosan poly 2,5-furandicarboxylic acid 1,3-adamantanediol ester comprises the following steps: 100g of 2,5-furandicarboxylic acid, 1,3-adamantanediol After adding 103 g of alcohol to 800 g of N-methylpyrrolidone, add 40 g of dicyclohexylcarbodiimide and 50 g of 4-dimethylaminopyridine to it, stir for 0.8 hours in an ice-water bath under a neon atmosphere, and then add Stir and react for 22 hours, then add chitosan 30g, continue to stir and react for 2.5 hours, after the reaction, it will settle out in water, wash the product 6 times with dichloromethane, and then place it in a vacuum oven at 81°C for 21 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com