A kind of antirust leak detection agent and preparation method thereof

A leak detection agent and formulation technology, which can be applied in the direction of detecting the appearance of fluid at the leak point, testing of machine/structural parts, instruments, etc., can solve the problems of high toxicity, flammability and explosion, and achieve good foaming, Effects of high wetting and detergency, good thickening power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

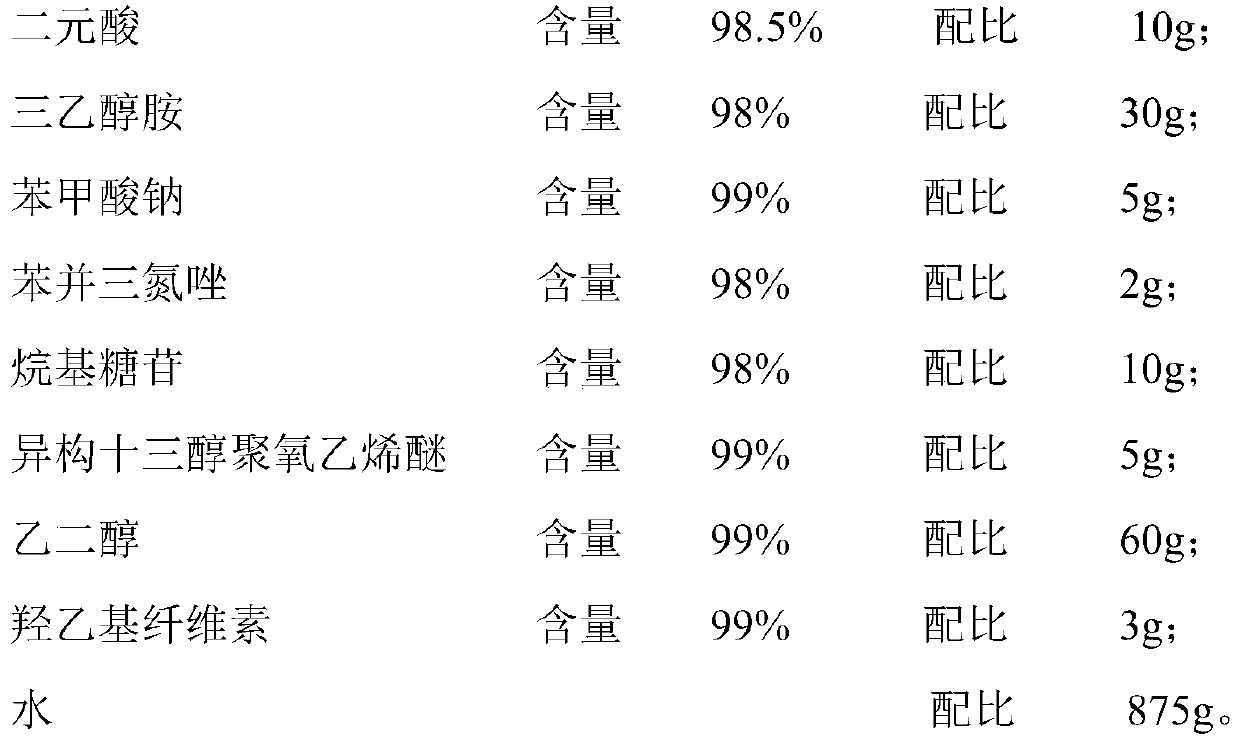

[0030] A kind of antirust leak detection agent, its composition is (taking 1000g antirust leak detection agent as example):

[0031]

[0032] The preparation method of above-mentioned anti-rust leak detection agent, the steps are as follows:

[0033] (1) Take part of the water and add it to A in the reaction kettle, raise the temperature to 30-40°C, add the formulated amount of dibasic acid to mix, then add the formulated amount of triethanolamine and stir, keep the reaction temperature at 40-42°C for 2.5-3.5 hours, Then add the sodium benzoate and benzotriazole of formula quantity and fully stir, form mixed solution A;

[0034] ⑵Add the formulated amount of hydroxyethyl cellulose and ethylene glycol into the reaction kettle B, mix thoroughly for 20-30 minutes, and control the temperature at 20-35°C to form a mixed solution B;

[0035] (3) Add the amount of alkyl glucoside and isotridecyl polyoxyethylene ether in the formula to the reaction kettle C and the water of 10 tim...

Embodiment 2

[0039] A kind of antirust leak detection agent, its composition is (taking 1000g antirust leak detection agent as example):

[0040]

[0041] The preparation method of the above-mentioned anti-rust leak detection agent is the same as Example 1.

Embodiment 3

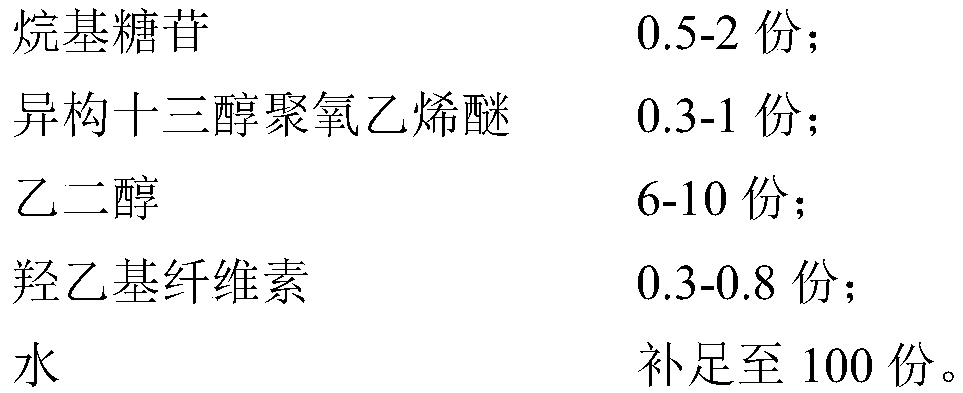

[0043] A kind of antirust leak detection agent, its composition and parts by weight are:

[0044]

[0045] Preferably, the dibasic acid is a dicarboxylic acid with nine to twelve carbons.

[0046] Preferably, the isomeric tridecyl alcohol polyoxyethylene ether contains 10 EO.

[0047] Preferably, the hydroxyethyl cellulose is HER-30000.

[0048] The preparation method of anti-rust leak detection agent as mentioned above, the steps are as follows:

[0049] (1) Take part of the water and add it to A in the reaction kettle, raise the temperature to 30-40°C, add the formulated amount of dibasic acid to mix, then add the formulated amount of triethanolamine and stir, keep the reaction temperature at 40-42°C for 2.5-3.5 hours, Then add the sodium benzoate and benzotriazole of formula quantity and fully stir, form mixed solution A;

[0050] ⑵Add the formulated amount of hydroxyethyl cellulose and ethylene glycol into the reaction kettle B, mix thoroughly for 20-30 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com