Preparation method and application of negative electrode material MXene for lithium battery

A negative electrode material, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as high cost, complicated preparation process, and danger of hydrofluoric acid, and achieve improved conductivity, obvious layer spacing, and preparation method safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of lithium battery negative electrode material MXene, comprising the steps of:

[0040] (1) Take 1g Ti 3 AlC 2 Make the positive electrode, metal lithium as the negative electrode, and then place the positive and negative electrodes in LiPF 6 / EC+DEC to form a battery system, charge and discharge 50 times;

[0041] (2) After charging and discharging, the obtained product was soaked in 0.3mol / L hydrochloric acid for 0.5h, and dried at 50°C for 20h to obtain MXene, a negative electrode material for lithium batteries.

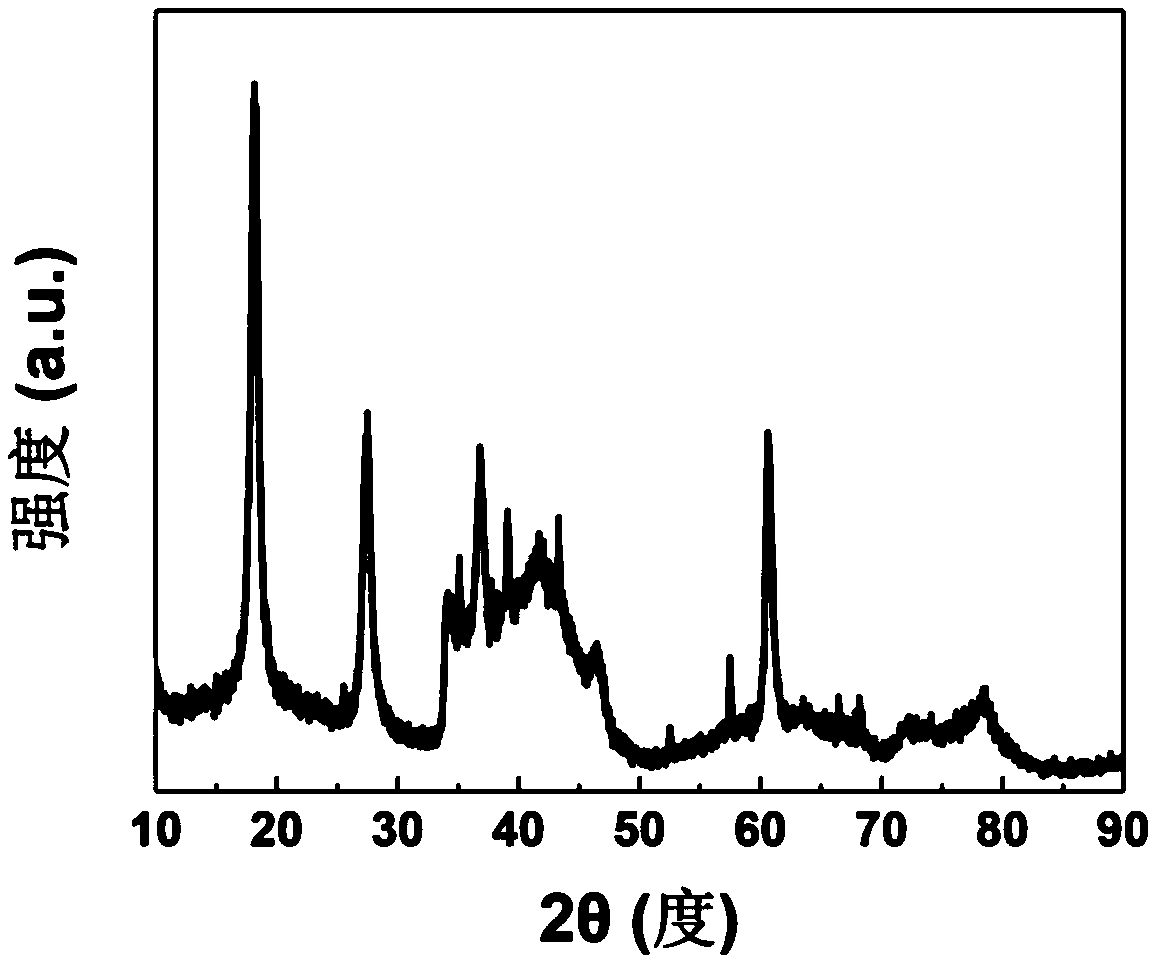

[0042] figure 1 is Ti in this example 3 AlC 2 XRD pattern. From figure 1 It can be seen that the peak is Ti 3 AlC 2 Standard peaks, no miscellaneous peaks, indicating that the precursor used is relatively pure Ti 3 AlC 2 .

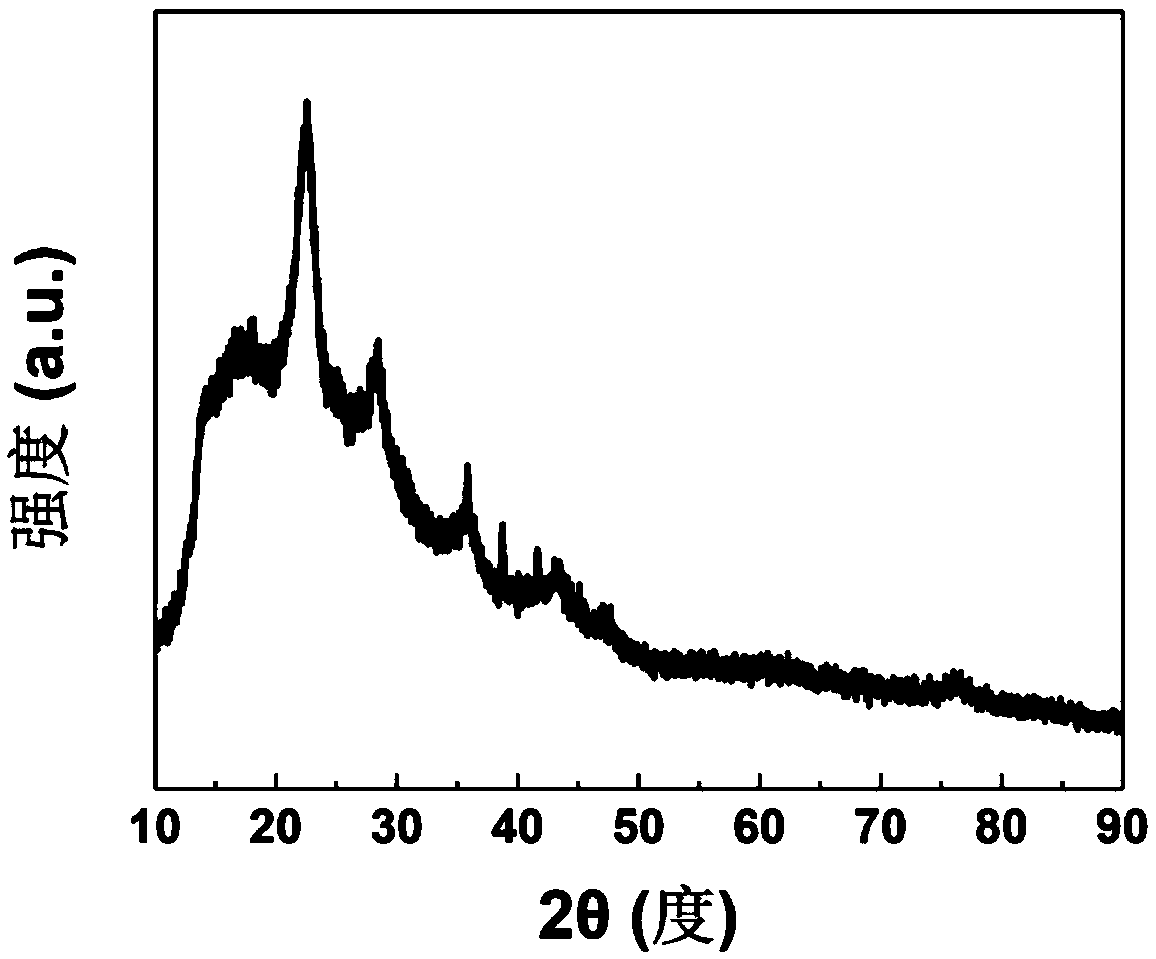

[0043] figure 2 It is the MXene material Ti prepared in this embodiment 3 C 2 The XRD pattern from figure 2 It can be seen that there is no peak of Al and no peak of lithium atoms in the negative e...

Embodiment 2

[0047] A preparation method of lithium battery negative electrode material MXene, comprising the steps of:

[0048] (1) Take 1g Ti 3 AlC 2 Make the positive electrode, metal lithium as the negative electrode, and then place the positive and negative electrodes in LiPF 6 / EC+PC to form a battery system, charge and discharge 10 times;

[0049] (2) After charging and discharging, soak the obtained product in 0.5 mol / L hydrochloric acid for 2 hours, and dry it at 60°C for 18 hours to obtain MXene, a negative electrode material for lithium batteries.

Embodiment 3

[0051] A preparation method of lithium battery negative electrode material MXene, comprising the steps of:

[0052] (1) Take 1g Ti 2 AlC is used as the positive electrode, metal sodium is used as the negative electrode, and then the positive and negative electrodes are placed in NaPF 6 / EC+DEC to form a battery system, charge and discharge 0.5 times;

[0053] (2) After charging and discharging, soak the obtained product in 0.1mol / L sulfuric acid for 1 hour, and dry it at 100°C for 10 hours to obtain MXene, a negative electrode material for lithium batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com