Graphene water purifying filter element and water purifier

An ene water purifier and ene water purification technology, applied in the field of graphene water purification filter elements and water purifiers, can solve problems such as user inconvenience, bacteria increase, and limited adsorption capacity of activated carbon filter materials, and achieve obvious purification effect and excellent filtration effect Full, watery, sweet and savory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

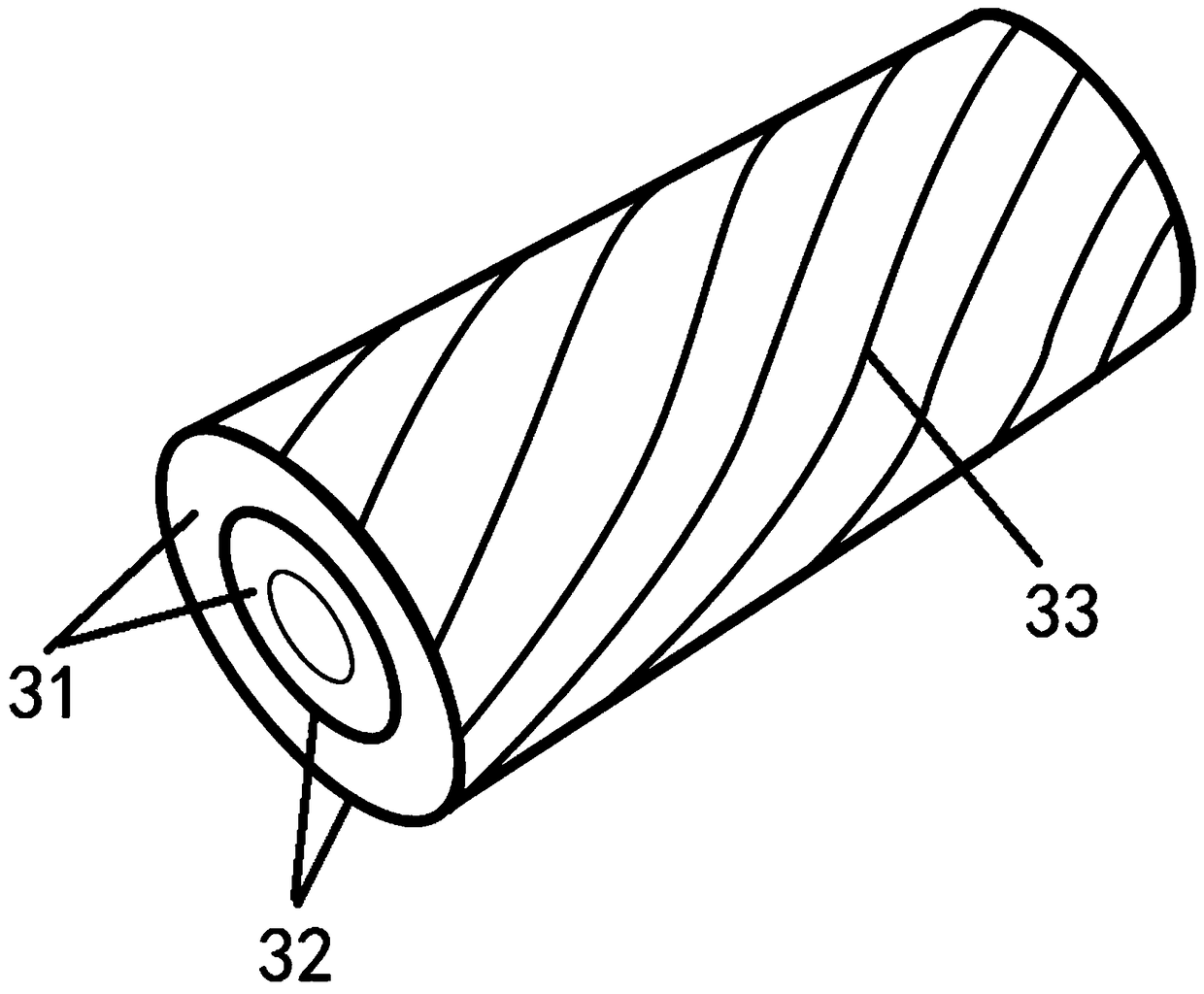

[0074] This implementation provides a kind of one-level graphene PP cotton composite filter element, such as figure 2 As shown, it is a hollow structure, and dense structure layers 31 and loose structure layers 32 are arranged alternately from the inside to the outside; the tight structure layers 31 and loose structure layers 32 are all prepared by graphene PP cotton composite materials;

[0075] The thicknesses of the compact structure layer 31 and the loose structure layer 32 are 1-3 μm and 8-10 μm respectively; the thickness of the composite filter element is 1.5 cm-2 cm.

[0076] The outer surface of the first-level graphene PP cotton composite filter core is provided with a plurality of spiral protrusions 33 in parallel, and the protrusions 33 extend along the height direction of the composite filter core;

[0077] The distance between the protruding structures 33 is 0.5-1 cm;

[0078] The inner surface and the outer surface of the first-level graphene PP cotton composi...

Embodiment 2

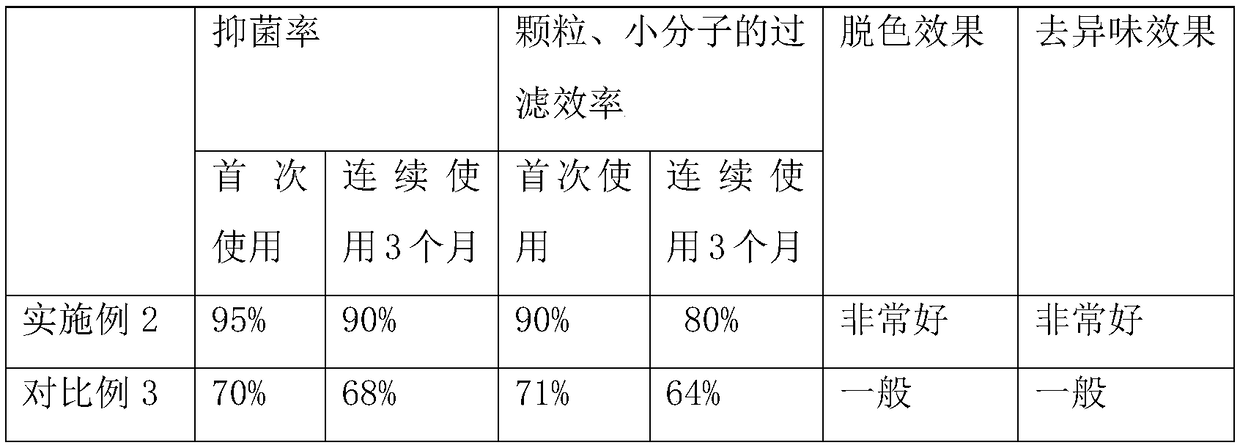

[0095] This embodiment provides a second-stage graphene-modified activated carbon filter element, which is prepared by using the following components in mass percentages:

[0096] Graphene 0.1%-10%;

[0097] Modified activated carbon 90-99.9%;

[0098] The preparation method of described modified activated carbon is:

[0099] After cleaning and drying the activated carbon raw material, add it to the modifier solution, stir evenly, soak for 2-3 hours, filter out the solid matter, wash and dry to obtain the modified activated carbon;

[0100] The mass ratio of the activated carbon to the modifier is 20:1-1:2; the mass fraction of the modifier in the modifier solution is 1%-30%.

[0101] The activated carbon raw material is one or more of coal-based activated carbon, coconut shell activated carbon, fruit shell activated carbon and wood activated carbon.

[0102] The modifying agent is one or more of organic silicon, methyl methacrylate, acrylate, sodium dodecylbenzenesulfonate...

Embodiment 3

[0110] The present embodiment provides a three-stage graphene modified activated carbon composite filter element, comprising the following components in mass percentages:

[0111] Graphene 0.1%-10%;

[0112] Sodium dodecylbenzene sulfonate modified activated carbon 90-99.9%.

[0113] The preparation method of described sodium dodecylbenzenesulfonate modified activated carbon is:

[0114] Add the activated carbon raw material to the sodium dodecylbenzenesulfonate solution with a concentration of 0.02-3.5mmol / L, shake at room temperature for 2-10 hours, then filter, separate and wash the activated carbon to prepare the grafted sodium sulfonate group modified activated carbon.

[0115] The activated carbon raw material used in the modified activated carbon has an iodine value of 800-1600, an ash content of <8%, and a mesh number of 600-1500.

[0116] The graphene is modified graphene oxide.

[0117] The preparation method of described three-stage graphene modified activated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com