Temperature-resistant oil removing agent for oily sewage of oil fields and preparation method of temperature-resistant oil removing agent

A technology for degreasing agent and oily sewage, applied in the direction of grease/oily substance/suspton removal device, separation method, chemical instrument and method, etc., can solve the problems of unsatisfactory effect of oily sewage, complicated preparation method, expensive price, etc. Achieve the effect of high oil removal efficiency, simple synthesis process and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

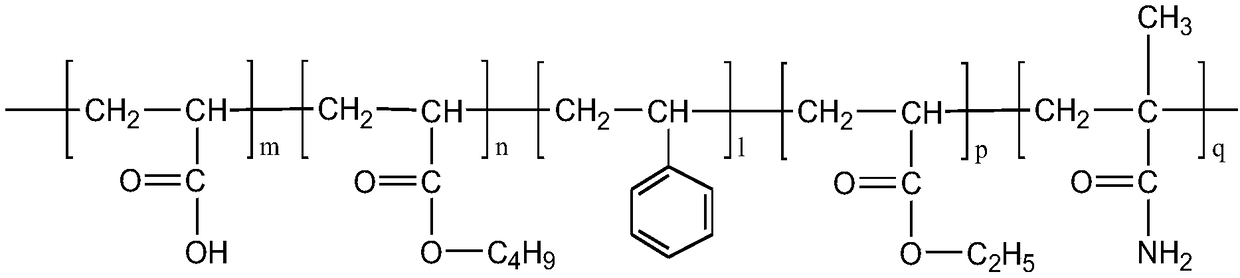

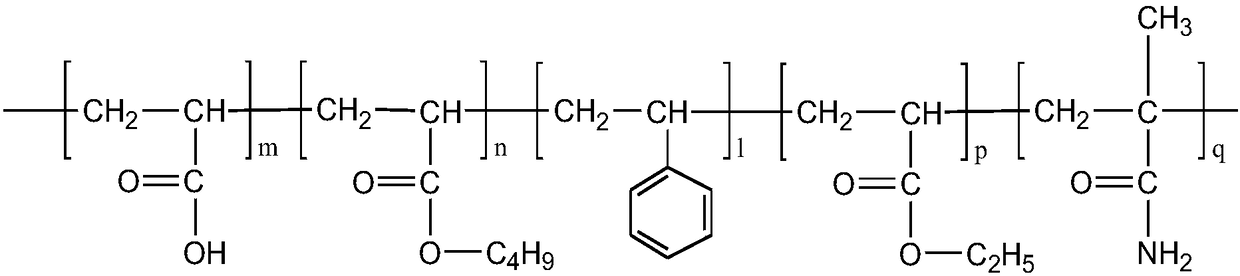

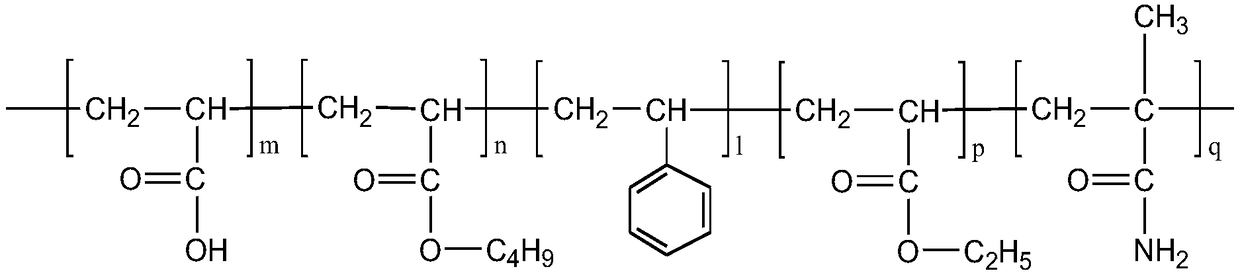

[0037] The preparation of example 1 degreasing agent A

[0038] (1) Weigh 1kg of acrylic acid, 15kg of butyl acrylate, 10kg of styrene, 4.2kg of ethyl acrylate, TX-100.6kg, 1kg of MS-1, 0.08kg of sodium lauryl sulfate, 0.4kg of 20% ammonia water and 20kg of water Place in the first reaction kettle, stir at room temperature for 1.5 hours, and the stirring speed is 80rpm to obtain a mixture solution;

[0039] (2) Add 50 kg of water and 59 kg of methacrylamide to the second reaction kettle, and stir at room temperature for 0.5 h to obtain an aqueous solution of methacrylamide;

[0040] (3) Transfer the aqueous methacrylamide solution in the second reaction kettle to the mixture solution in the first reaction kettle, and stir at room temperature for 20 minutes to obtain an emulsion;

[0041] (4) 80% of the mass ratio of the emulsion in the first reactor is transferred to the first head tank;

[0042] (5) Add 0.6kg of hydrogen peroxide and 2kg of water in the second high tank;

...

Embodiment 2

[0053] The preparation of embodiment 2 degreasing agent B

[0054] (1) Weigh 1kg of acrylic acid, 4kg of butyl acrylate, 30kg of styrene, 6.0kg of ethyl acrylate, TX-101.0kg, 0.4kg of MS-1, 0.05kg of sodium lauryl sulfate, 0.1kg of 20% ammonia water and water 10 kg was placed in the first reaction kettle, stirred at room temperature for 1 hour, and the stirring speed was 50 rpm to obtain a mixture solution;

[0055](2) Add 10 kg of water and 20 kg of methacrylamide to the second reaction kettle, and stir at room temperature for 1 hour to obtain an aqueous solution of methacrylamide;

[0056] (3) Transfer the methacrylamide aqueous solution in the second reaction kettle to the mixture solution in the first reaction kettle, and stir at room temperature for 10 minutes to obtain an emulsion;

[0057] (4) 70% of the mass ratio of the emulsion in the first reactor is transferred to the first head tank;

[0058] (5) Add 0.1kg of hydrogen peroxide and 0.5kg of water in the second hi...

Embodiment 3

[0069] The preparation of embodiment 3 degreasing agent C

[0070] (1) Weigh 1kg of acrylic acid, 20kg of butyl acrylate, 14.0kg of styrene, 9.8kg of ethyl acrylate, TX-100.3kg, 1.5kg of MS-1, 0.2kg of sodium lauryl sulfate, 0.5kg of 20% ammonia water and 30 kg of water was placed in the first reaction kettle, stirred at room temperature for 2.5 hours, and the stirring speed was 110 rpm to obtain a mixture solution;

[0071] (2) Add 100 kg of water and 45.0 kg of methacrylamide to the second reaction kettle, and stir at room temperature for 2 hours to obtain an aqueous solution of methacrylamide;

[0072] (3) Transfer the aqueous methacrylamide solution in the second reaction kettle to the mixture solution in the first reaction kettle, and stir at room temperature for 30 minutes to obtain an emulsion;

[0073] (4) 90% of the mass ratio of the emulsion in the first reactor is transferred to the first head tank;

[0074] (5) Add 1.0kg of hydrogen peroxide and 5kg of water in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com