Aqueous coiled material over-printing vanish and preparation method thereof

A technology for covering varnishes and coils, applied in coatings, epoxy resin coatings, etc., can solve the problems that need to be further improved, and achieve the effects of good gloss and color retention, clarity and transparency, and fullness of the coating film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

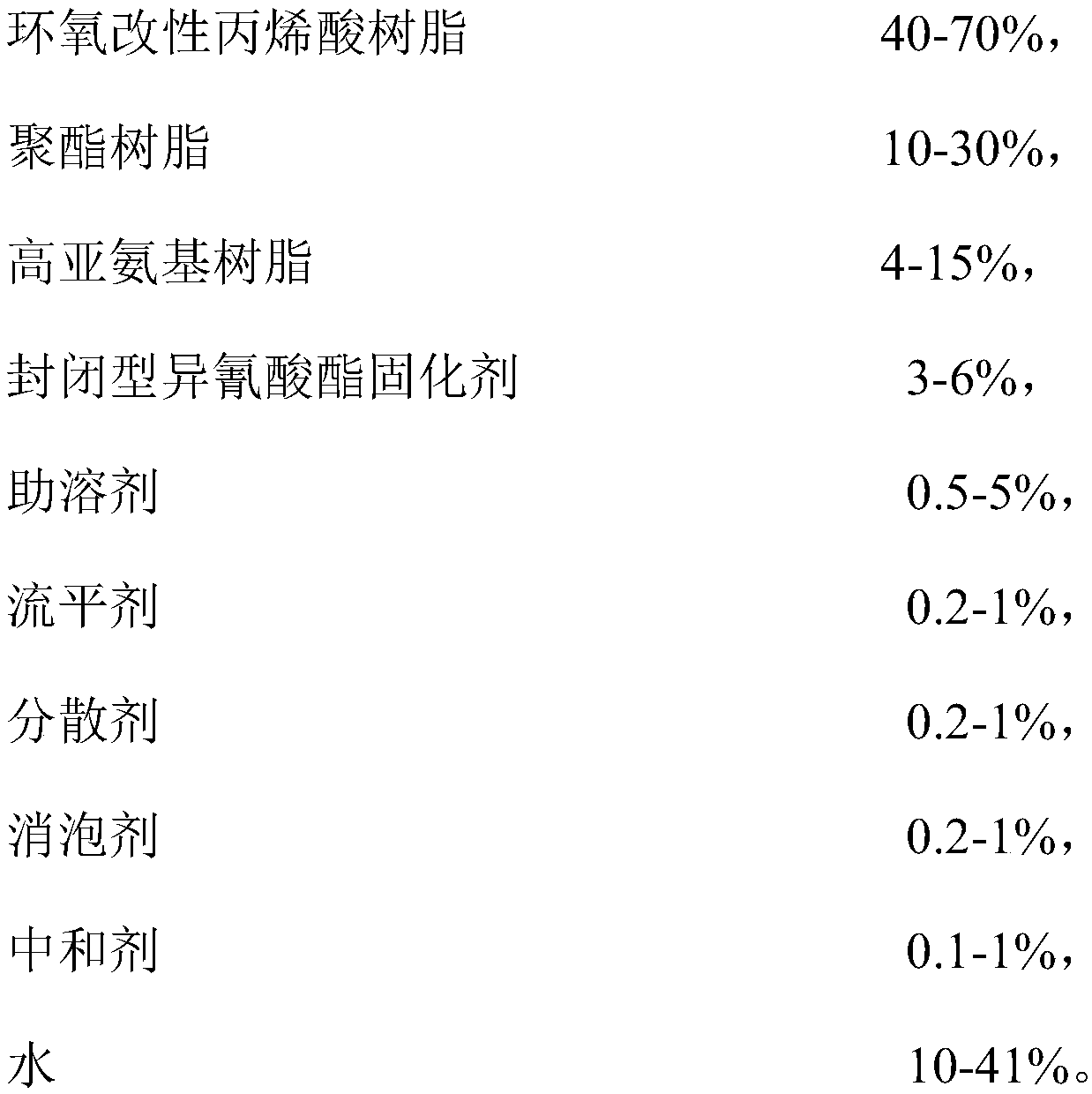

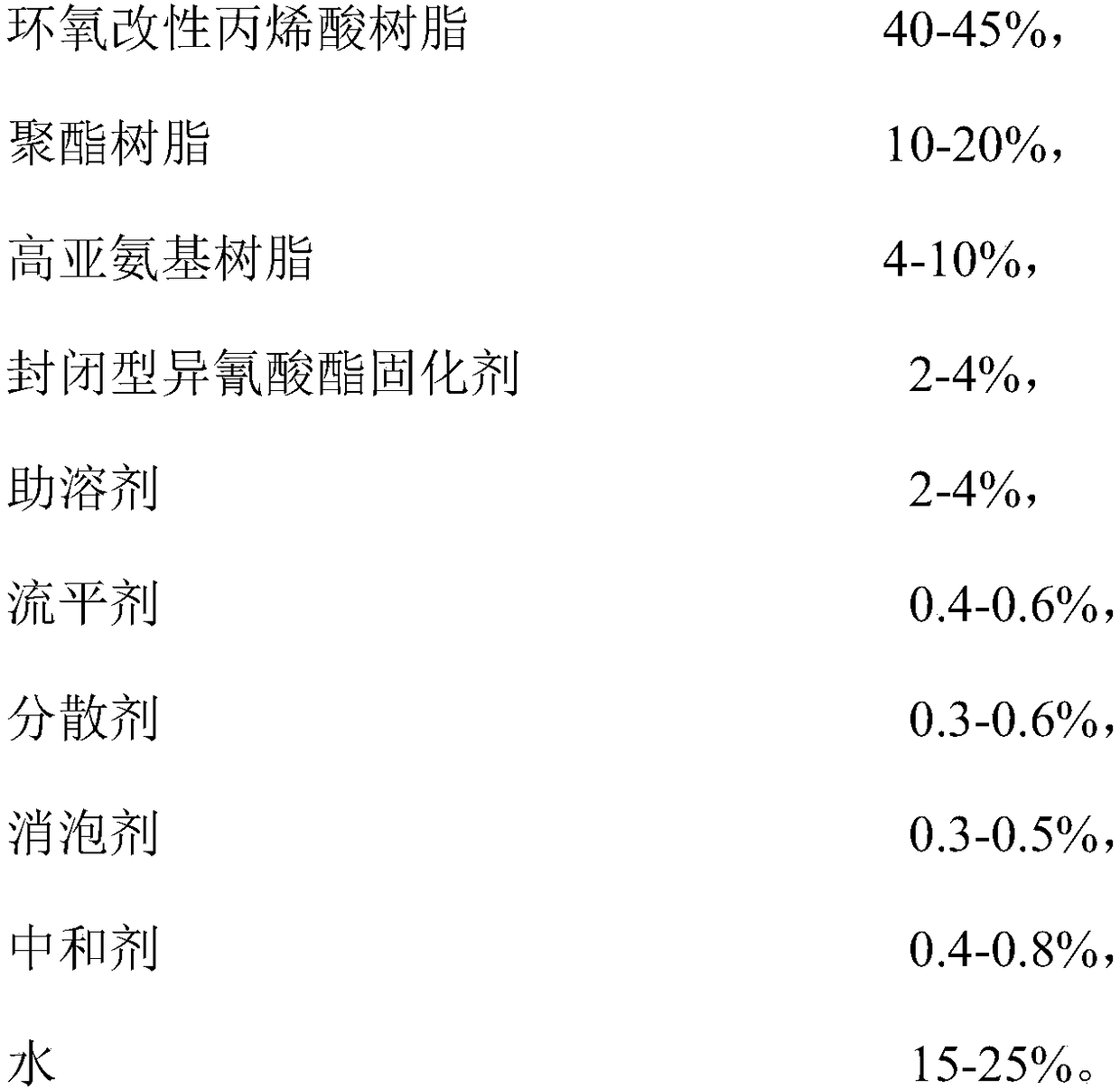

Method used

Image

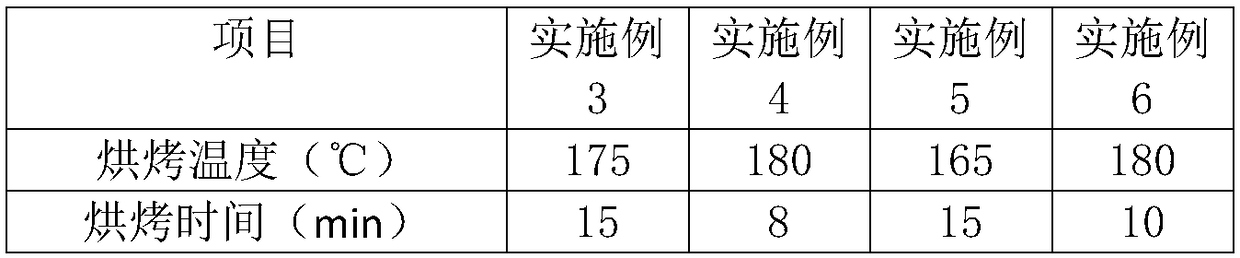

Examples

Embodiment 1

[0030] Preparation of epoxy-modified acrylic resin:

[0031] (1) Add 30 parts by weight of ethylene glycol monobutyl ether into the reactor and heat up to 100 ° C, dropwise add 70 parts by weight containing 11% acrylic acid, 7% methacrylic acid, 5% ethyl acrylate, 45% butyl acrylate, 17% E-51 epoxy resin, 10% hydroxyethyl acrylate, 5% hydroxypropyl acrylate acrylic mixed monomer, the amount added is the weight of hydroxypropyl acrylate acrylic mixed monomer A mixture of 0.3% cumene peroxide and 0.1% n-butyl mercaptan was added dropwise within 5 hours;

[0032] (2) reaction system was incubated for 2 hours, then added cumene peroxide of 0.1 parts by weight, continued to be incubated for 4 hours;

[0033] (3) Subsequently, the temperature of the reaction system is lowered to below 85°C, and the pH value is neutralized to 6.5 with ammonia water or an organic amine neutralizer, and finally an appropriate amount of water is added to adjust the solid content to 55%, that is, the ep...

Embodiment 2

[0035] Preparation of epoxy-modified acrylic resin:

[0036](1) Add 50 parts by weight of ethylene glycol monobutyl ether into the reactor and heat up to 120°C, and dropwise add 50 parts by weight of acrylic acid containing 15%, methacrylic acid of 8%, ethyl acrylate of 20%, butyl acrylate, 10% E-44 epoxy resin, 9% hydroxyethyl acrylate, 4% hydroxypropyl acrylate acrylic mixed monomer, the amount added is the weight of hydroxypropyl acrylate acrylic mixed monomer A mixture of 0.4% cumene peroxide and 0.08% n-butylmercaptan was added dropwise within 6 hours;

[0037] (2) the reaction system was incubated for 2 hours, then added 0.2 parts by weight of cumene peroxide, and continued to be incubated for 3 hours;

[0038] (3) Subsequently, the temperature of the reaction system is lowered to below 70° C., the pH value is neutralized to 6.5 with ammonia water or an organic amine neutralizer, and finally an appropriate amount of water is added to adjust the solid content to 45%.

Embodiment 3

[0040] First take each raw material according to the following raw material proportioning: Example 1 Epoxy-modified acrylic resin 40%, polyester resin 18%, 308 high methylated melamine cross-linking agent 4%, blocked alicyclic polyisocyanate curing agent 5%, propylene glycol ether 0.5%, acrylate leveling agent 0.4%, polyacrylate block copolymer dispersant 0.5%, non-organic silicon defoamer 0.5%, dimethylethanolamine 0.1%, water 31%. Then add the weighed epoxy-modified acrylic resin, polyester resin and water into the high-speed disperser to disperse and stir evenly, and finally add 308 high-etherified melamine crosslinking agent, blocked alicyclic polyisocyanate curing agent, and propylene glycol ether , acrylate leveling agent, polyacrylate block copolymer dispersant, non-organic silicon defoamer and dimethylethanolamine, set the stirring speed to 800r / min, and stir at high speed for 30 minutes to obtain a water-based coil Varnish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com