Preparation method of iron oxide/carbon fiber composite lithium ion battery negative electrode material

A technology of iron oxides and composite materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that the electrochemical performance needs to be improved, the electrode manufacturing process is complicated, and the battery negative electrode material cannot be used directly as an electrode, etc., and achieves excellent results. The effect of electrochemical performance, controllable morphology, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of MIL-88A / PAN composite fiber

[0034] Dissolve 0.480 g of MIL-88A in 3 mL of dimethylformamide (DMF) (that is, the content of MIL-88A is 60 wt%), and disperse it ultrasonically for 20 min to obtain a suspension. Weigh 0.32g PAN and dissolve it in the above suspension, then put the mixed solution in a water bath at 65°C and stir for 18 hours, take it out, leave it at room temperature for 4 hours, and then electrospin the solution. The process conditions of electrospinning are set as follows: the voltage is 15kV, receiving distance 16cm, solution flow rate 200μL / min, drying in a drying oven at 80°C to prepare MIL-88A / PAN fibers.

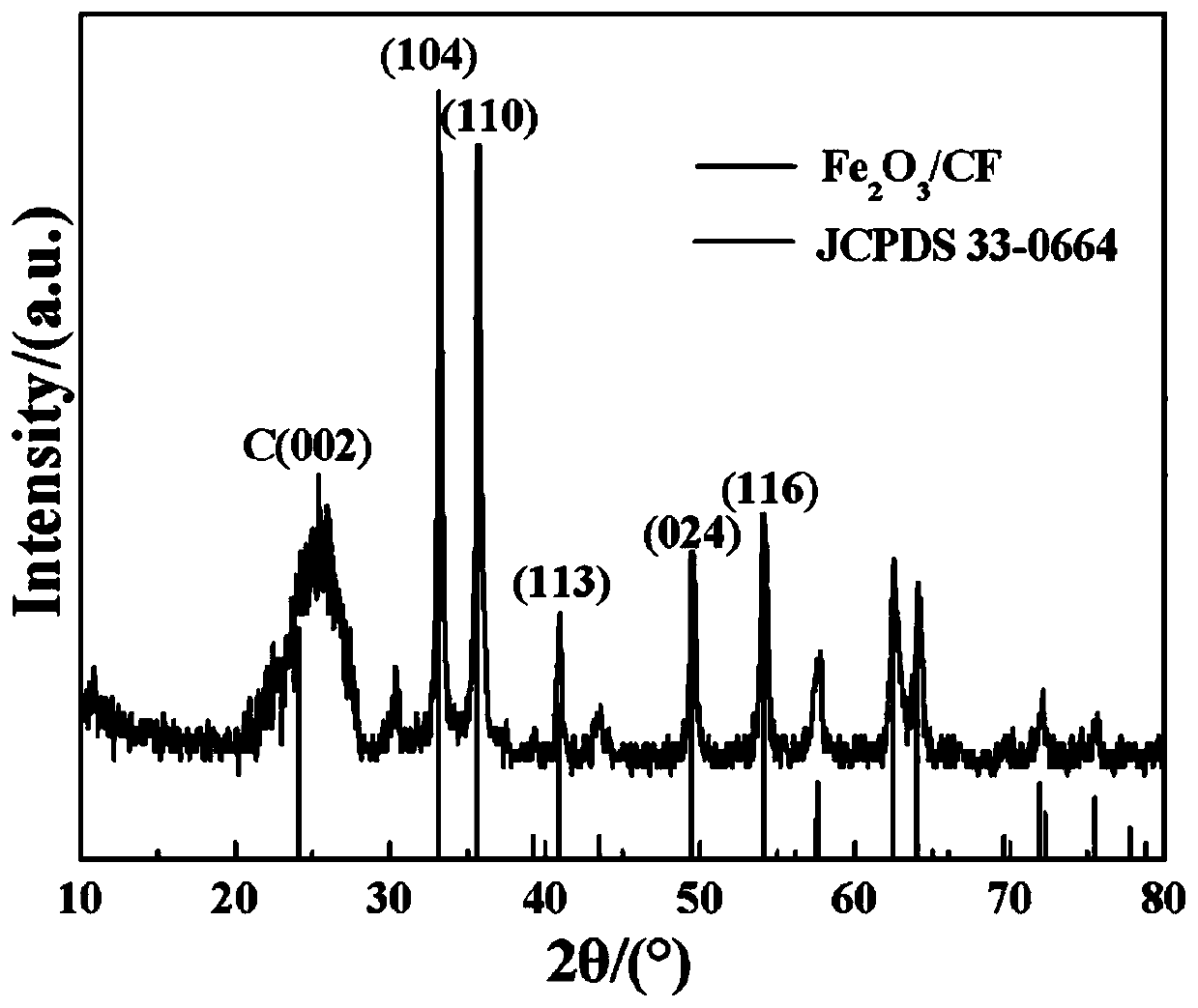

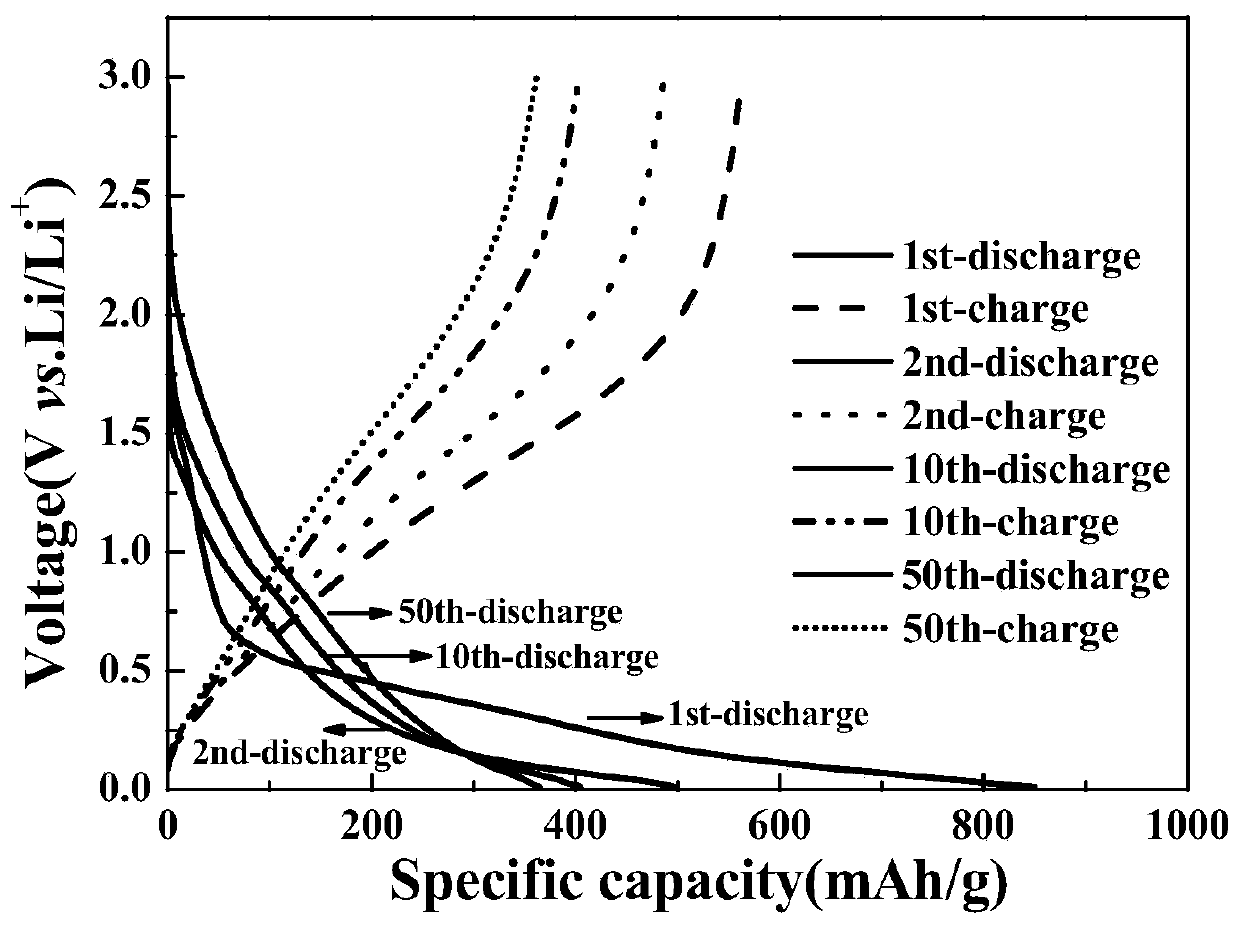

[0035] (2) Preparation of iron oxide / carbon fiber

[0036] The MIL-88A / PAN fibers were placed in a tube furnace, and pre-oxidized at 250 °C for 2 h under air conditions, and then nitrogen (N 2 >99.99%), heat treatment at 400°C for 3 hours, and then naturally cool down to room temperature to obtain iron oxide / carbon fiber comp...

Embodiment 2

[0041] Dissolve 0.0355 g of MIL-88A in 3 mL of dimethylformamide (that is, the content of MIL-88A is 10 wt %), and ultrasonically disperse for 20 min to obtain a suspension. Weigh 0.32g PAN and dissolve it in the above suspension, then put the mixed solution in a water bath at 65°C and stir for 18 hours, take it out, leave it at room temperature for 4 hours, and then electrospin the solution. The process conditions of electrospinning are set as follows: the voltage is 10kV, receiving distance 12cm, solution flow rate 200μL / min, drying in an oven at 80°C to prepare MIL-88A / PAN fibers.

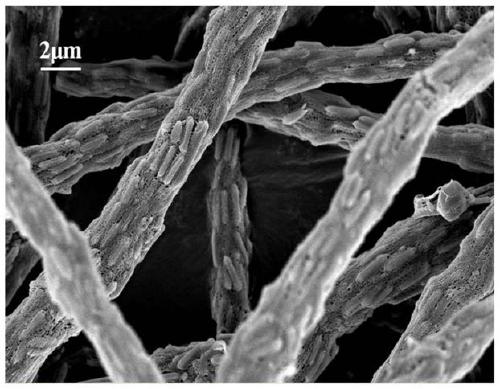

[0042] The MIL-88A / PAN fibers were placed in a tube furnace, and pre-oxidized at 250 °C for 2 h under air conditions, and then nitrogen (N 2 >99.99%), heat treatment at 400°C for 3h, then naturally cool down to room temperature to obtain iron oxide / carbon fiber (Fe 2 o 3 / CF) composite material. From Figure 4 It can be seen that there are rod-shaped iron oxides distributed on the surface of...

Embodiment 3

[0045] Dissolve 0.080 g of MIL-88A in 3 mL of dimethylformamide (that is, the content of MIL-88A is 20 wt %), and disperse it ultrasonically for 20 min to obtain a suspension. Weigh 0.32g PAN and dissolve it in the above suspension, then put the mixed solution in a water bath at 65°C and stir for 18 hours, take it out, leave it at room temperature for 4 hours, and then electrospin the solution. The process conditions of electrospinning are set as follows: the voltage is 13kV, the receiving distance is 10cm, the solution flow rate is 200μL / min, and dried in a drying oven at 80°C to prepare MIL-88A / PAN fibers.

[0046] The MIL-88A / PAN fibers were placed in a tube furnace, and pre-oxidized at 250 °C for 2 h under air conditions, and then nitrogen (N 2 >99.99%), heat treatment at 400°C for 3h, then naturally cool down to room temperature to obtain iron oxide / carbon fiber (Fe 2 o 3 / CF) composite material. From Figure 6 It can be seen that there are rod-shaped iron oxides dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com