Multi-void organic volatile adsorption nano calcium carbonate composite material and preparation method thereof

A technology of nano-calcium carbonate and organic volatiles, applied in the direction of botanical equipment and methods, separation methods, chemical instruments and methods, etc., can solve the problems of reducing the use efficiency of photocatalysts, failing to achieve the purpose of removal, and single photocatalysts. Achieve good oxidation and sterilization effects, long duration and good recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

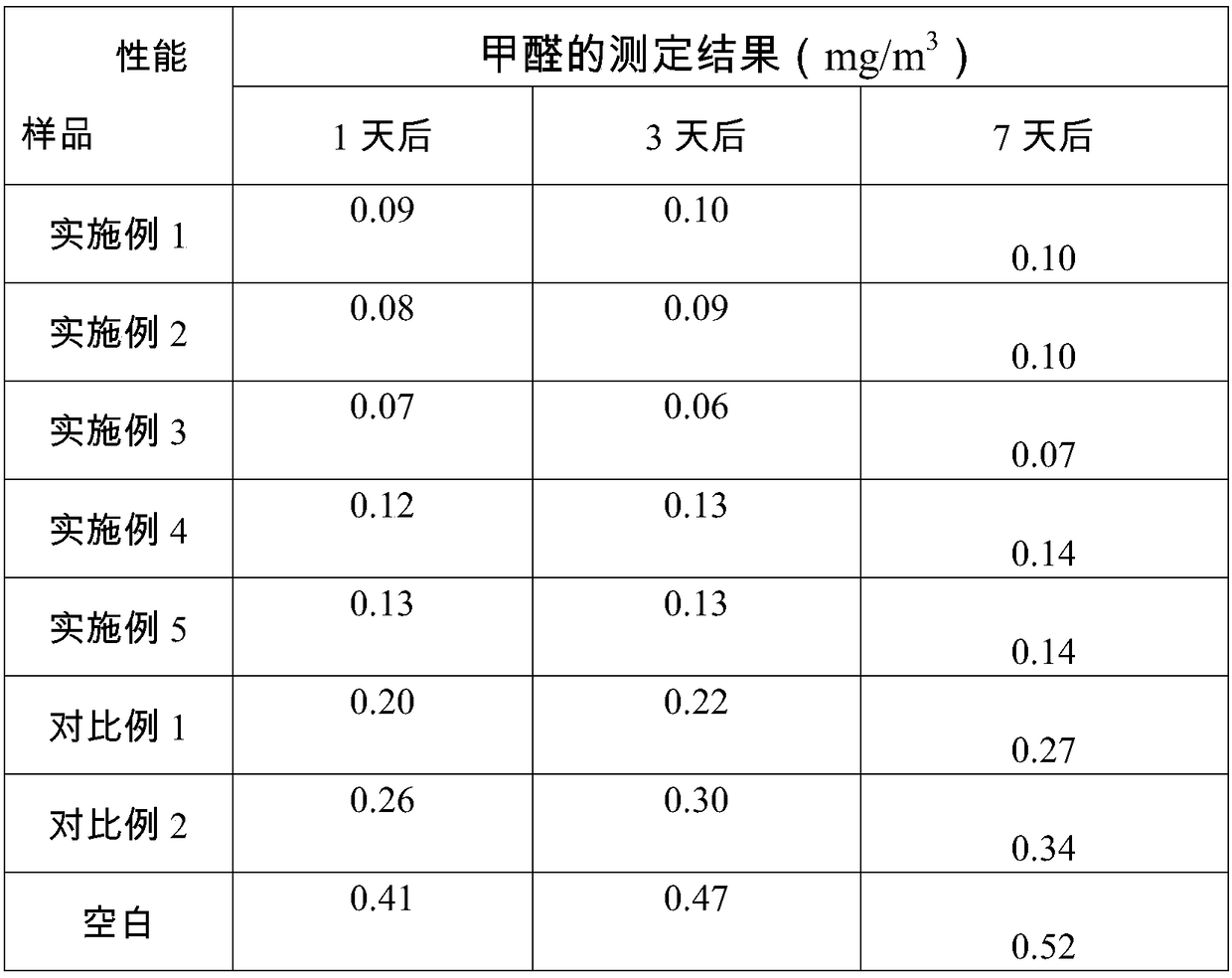

Examples

Embodiment 1

[0026] In this embodiment, the multi-void nano-calcium carbonate composite material for adsorbing organic volatiles is made of the following raw materials in parts by weight: 50 parts of nano-calcium carbonate, 50 parts of modified kaolin, 10 parts of simethicone, 15 parts of bamboo charcoal, and tripolyphosphoric acid 10 parts of sodium, 100 parts of ethanol, 12 parts of methylcellulose, 7 parts of hydroxyapatite, 8 parts of fungicide;

[0027] Among them, the fungicide is composed of calcium hypochlorite, nano-titanium dioxide, and β-cyclodextrin mixed according to the mass ratio of 1:1:0.3; the particle size of nano-calcium carbonate is 60nm, and nano-calcium carbonate is modified nano-calcium carbonate. The method is as follows: 70ml of 0.5mol / L calcium nitrate and 70ml of 0.5mol / L sodium carbonate were stirred and reacted at 40°C for 20 minutes, the stirring was stopped, and the precipitates were separated, washed, and dried in turn to obtain nano-calcium carbonate; The m...

Embodiment 2

[0034] In this embodiment, the multi-void nano-calcium carbonate composite material for adsorbing organic volatiles is made of the following raw materials in parts by weight: 90 parts of nano-calcium carbonate, 90 parts of modified kaolin, 25 parts of simethicone, 30 parts of bamboo charcoal, and tripolyphosphoric acid 16 parts of sodium, 200 parts of ethanol, 18 parts of methylcellulose, 16 parts of hydroxyapatite, 15 parts of fungicide;

[0035]Among them, the fungicide is composed of calcium hypochlorite, nano-titanium dioxide, and β-cyclodextrin mixed according to the mass ratio of 1:1:0.3; the particle size of nano-calcium carbonate is 100nm, and nano-calcium carbonate is modified nano-calcium carbonate. The method is as follows: 70ml of 0.5mol / L calcium nitrate and 70ml of 0.5mol / L sodium carbonate are stirred and reacted at 40°C for 30 minutes, the stirring is stopped, and the precipitates are separated, washed, and dried in turn to obtain nano-calcium carbonate; The mo...

Embodiment 3

[0042] In this embodiment, the multi-void nano-calcium carbonate composite material for adsorbing organic volatiles is made of the following raw materials in parts by weight: 70 parts of nano-calcium carbonate, 70 parts of modified kaolin, 18 parts of simethicone, 23 parts of bamboo charcoal, and tripolyphosphoric acid 13 parts of sodium, 150 parts of ethanol, 15 parts of methyl cellulose, 12 parts of hydroxyapatite, 11 parts of fungicide;

[0043] Among them, the bactericide is composed of calcium hypochlorite, nano-titanium dioxide, and β-cyclodextrin mixed according to the mass ratio of 1:1:0.3; the particle size of nano-calcium carbonate is 80nm, and nano-calcium carbonate is modified nano-calcium carbonate. The method is as follows: 70ml of 0.5mol / L calcium nitrate and 70ml of 0.5mol / L sodium carbonate were stirred and reacted at 40°C for 25 minutes, the stirring was stopped, and the precipitates were separated, washed, and dried in turn to obtain nano-calcium carbonate; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com