One-dimensional micro-nanorod LiMgVO4 material and preparation method thereof

A micro-nano, rod-shaped technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of large particle size, low sample purity, difficult to control, etc., and achieve high material purity, good crystal morphology, and size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

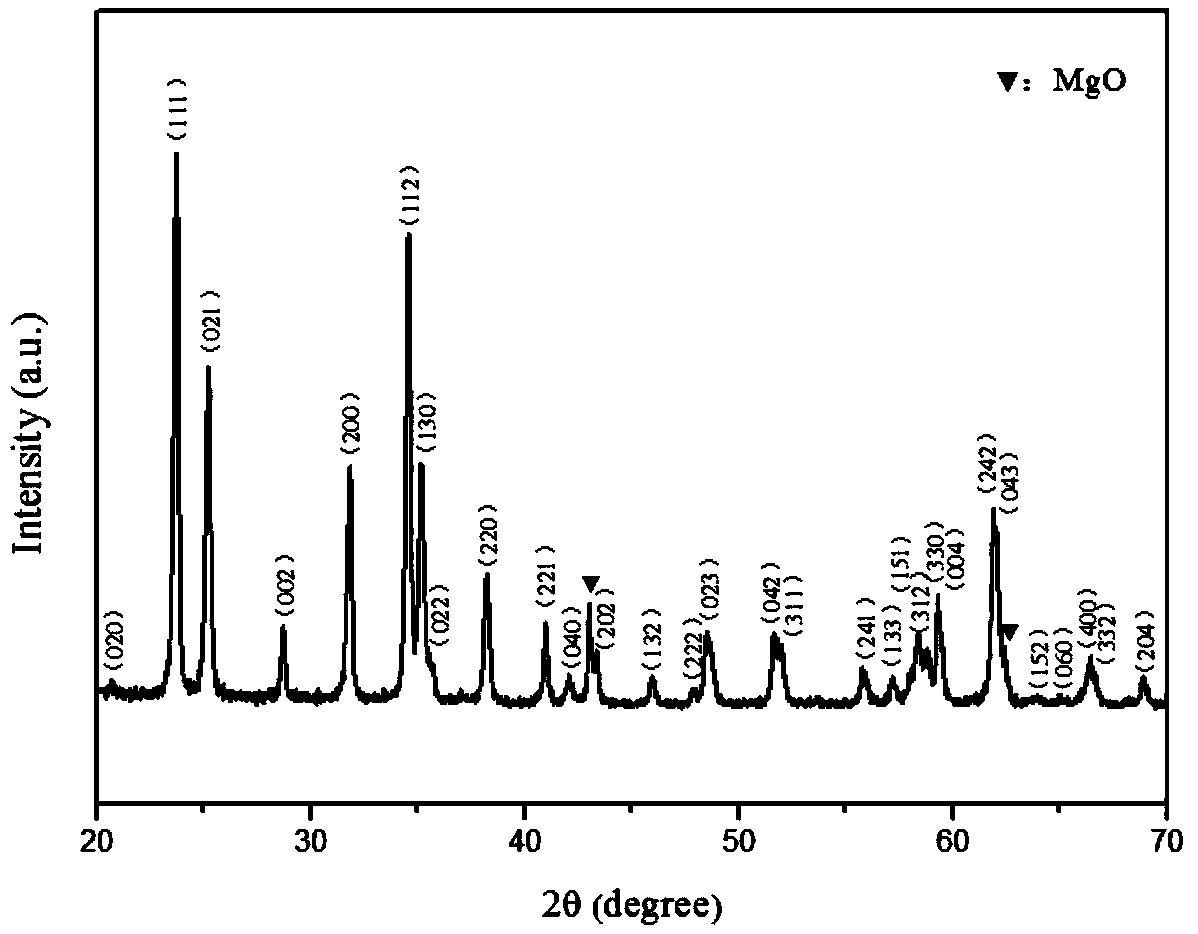

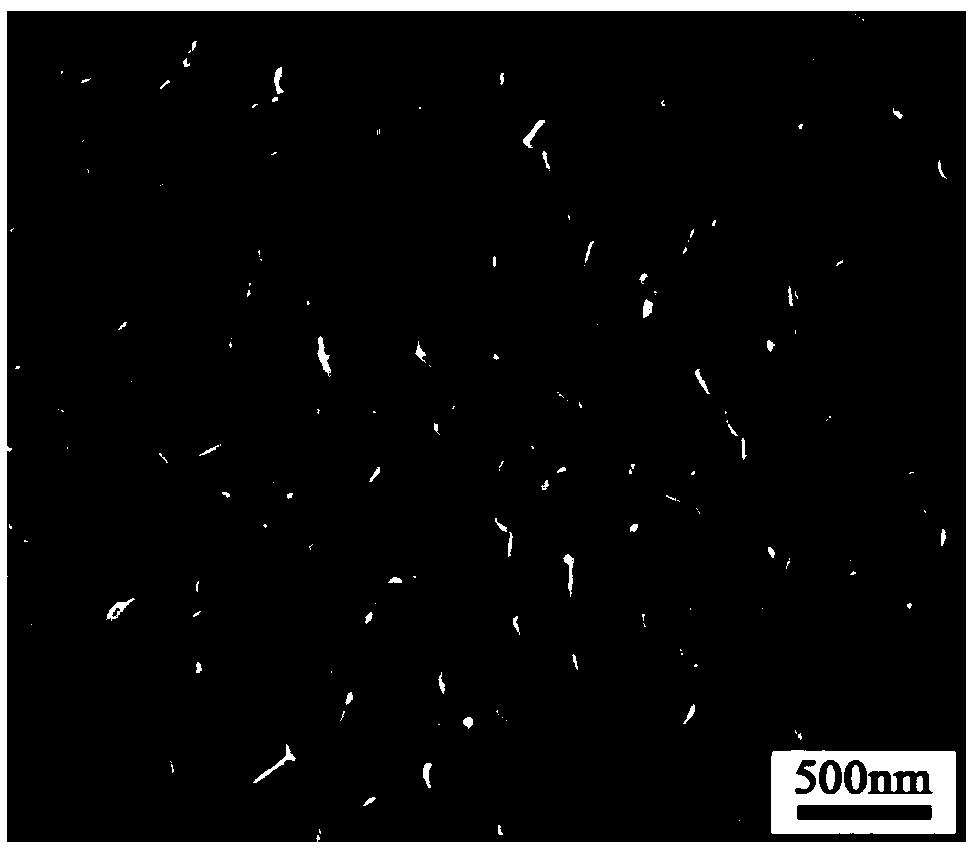

Embodiment 1

[0031] Molar ratio (LiOH·H 2 O:MgO:NH 4 VO 3 =1:1:1), take respectively the lithium hydroxide of 0.316g, the magnesium oxide of 0.276g and the ammonium metavanadate of 0.800g as raw material, grind this raw material 15min and make it mix homogeneously; Take by weighing 1.454g in addition The sodium nitrate of 1.729g and the potassium nitrate of 1.729g, grind 15min to make it mix homogeneously, as the mixed molten salt (NaNO 3 -KNO 3 ). The molten salt was mixed with the raw material and ground for 2 minutes to obtain a precursor; the precursor obtained above was transferred to a heating furnace for heat treatment in an air atmosphere, the heat treatment temperature was 300 ° C, and the reaction time was 3 hours. When the reaction time expired, LiMgVO was obtained after natural cooling 4 -Salt mixed powder; LiMgVO obtained above 4 -Salt mixed powder was washed with deionized water several times to remove the molten salt, filtered and dried at 100°C for 3 hours to obtain r...

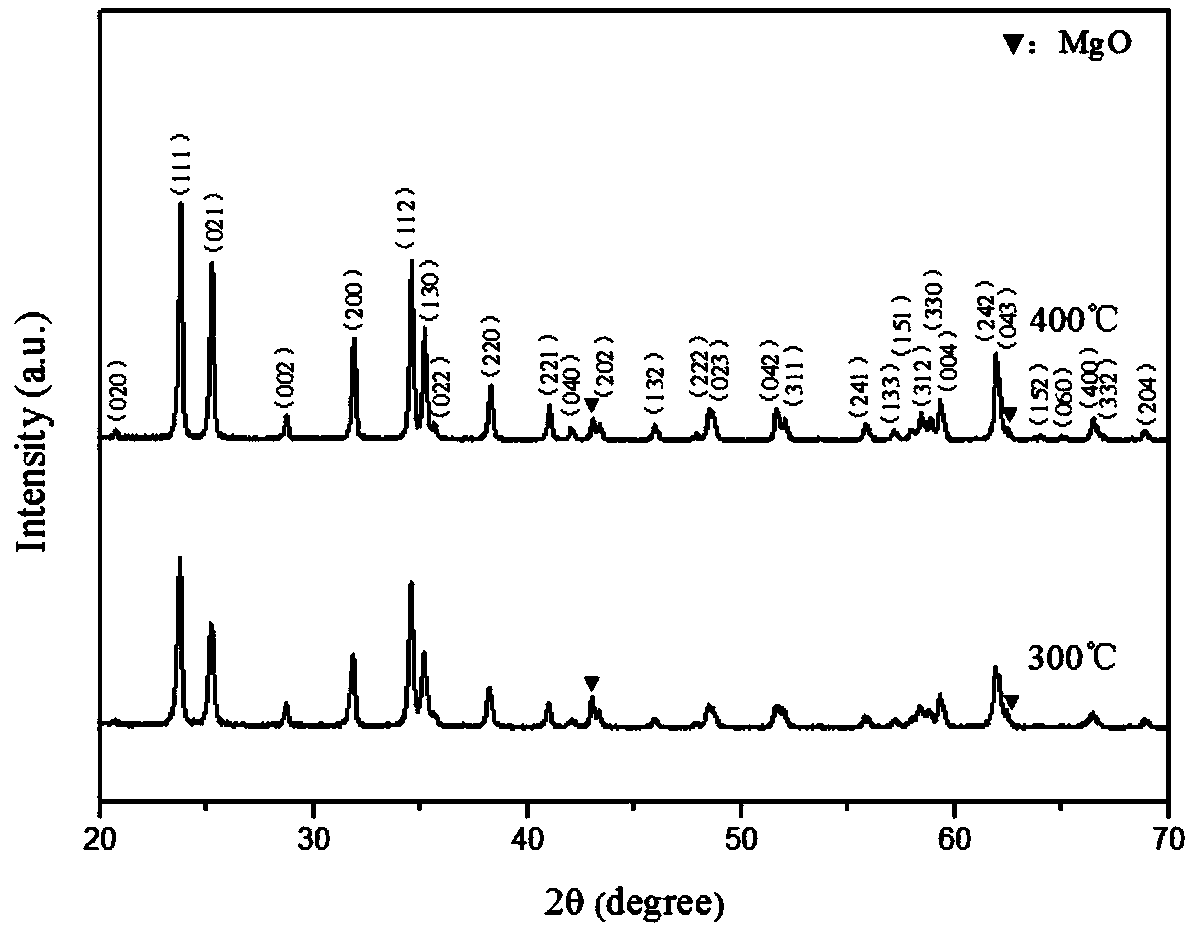

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is that the heat treatment temperatures are respectively 300°C and 400°C, and the specific implementation process is as follows:

[0035] Molar ratio (LiOH·H 2 O:MgO:NH 4 VO 3 =1:1:1), take respectively the lithium hydroxide of 0.316g, the magnesium oxide of 0.276g and the ammonium metavanadate of 0.800g as raw material, grind this raw material 15min and make it mix homogeneously; Take by weighing 1.454g in addition The sodium nitrate of 1.729g and the potassium nitrate of 1.729g, grind 15min to make it mix homogeneously, as the mixed molten salt (NaNO 3 -KNO 3 ). Mix and grind the molten salt with the raw material for 2 minutes to obtain a precursor; transfer the precursor obtained above to a heating furnace, and perform heat treatment in an air atmosphere. The heat treatment temperatures are 300°C and 400°C respectively, and the reaction time is 3h. When the time expires, LiMgVO is obtained after natural coo...

Embodiment 3

[0038] The difference between this embodiment and Example 1 is that the reaction times are respectively 1h, 3h and 5h, and the specific implementation process is as follows:

[0039] Molar ratio (LiOH·H 2 O:MgO:NH 4 VO 3 =1:1:1), take respectively the lithium hydroxide of 0.316g, the magnesium oxide of 0.276g and the ammonium metavanadate of 0.800g as raw material, grind this raw material 15min and make it mix homogeneously; Take by weighing 1.454g in addition The sodium nitrate of 1.729g and the potassium nitrate of 1.729g, grind 15min to make it mix homogeneously, as the mixed molten salt (NaNO 3 -KNO 3 ). The molten salt was mixed with raw materials and ground for 2 minutes to obtain a precursor; the precursor obtained above was transferred to a heating furnace, and heat-treated in an air atmosphere at a temperature of 300°C, and the reaction time was 1 h, 3 h, and 5 h, respectively. When the reaction time expired, LiMgVO was obtained after natural cooling 4 -Salt mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com