Novel microcontact printing system for cell patterning

A technology of micro-contact printing and cell patterning, which is applied in specific-purpose bioreactors/fermenters, biochemical instruments, biochemical cleaning devices, etc., can solve the problems of opaque patterns, long time consumption, etc. Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

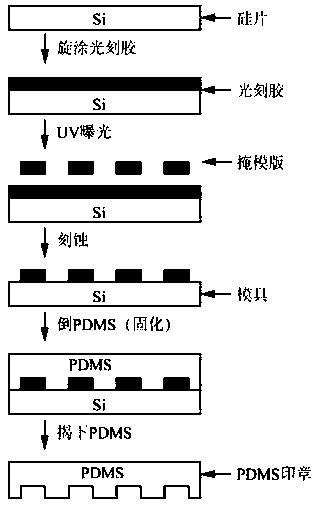

Method used

Image

Examples

Embodiment 1

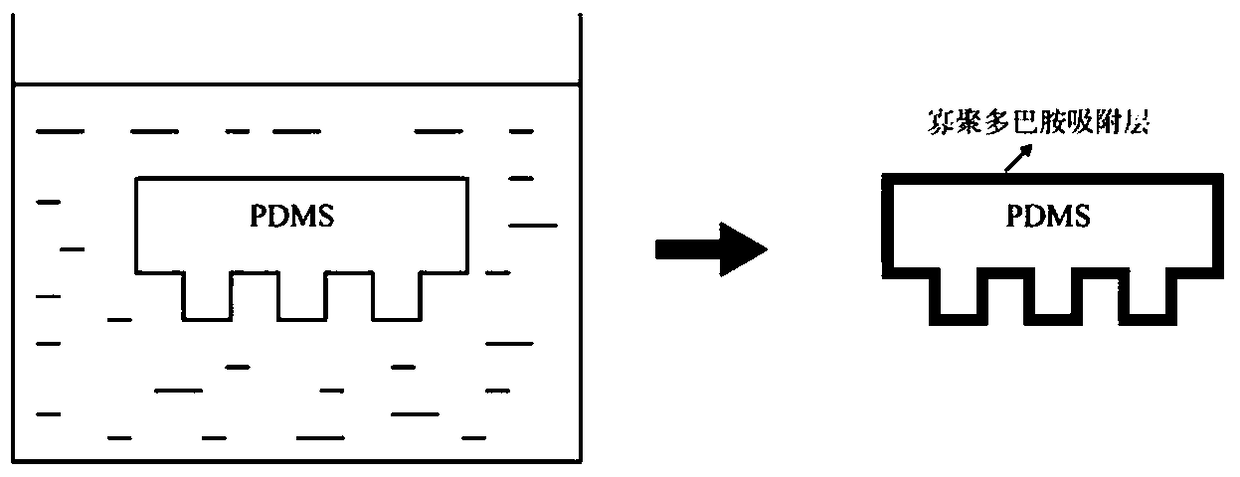

[0032] 1. Preparation of oligodopamine

[0033] Put the dopamine monomer molecule into a Tris-HCl buffer solution with a pH of 8.5 for 8 hours to obtain a substance with a black precipitate. The solution was centrifuged at 15000 rpm to obtain a yellow supernatant solution containing oligodopamine.

[0034] 2. Print oligodopamine patterns on the surface of the quartz plate modified with polyethylene glycol silane

[0035] (1) Oxidize the quartz plate

[0036] Quartz sheet (8*8*0.5mm 3 , Purchased from Donghai County Weida Quartz Products Co., Ltd.) Followed by ultrasonic cleaning in acetone and absolute ethanol for 10 minutes, then boiling in a mixture of concentrated sulfuric acid and hydrogen peroxide (volume ratio 3: 1) for 1 hour, cleaning with ultrapure water, and drying . The quartz piece was placed in a low-temperature plasma processor to oxidize for 6 minutes.

[0037] (2) Inert modification of quartz plates

[0038] The oxidized quartz chip was soaked in a toluene solution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com