A negative electrode conductive agent for lithium ion battery and a preparation method of a battery containing the conductive agent

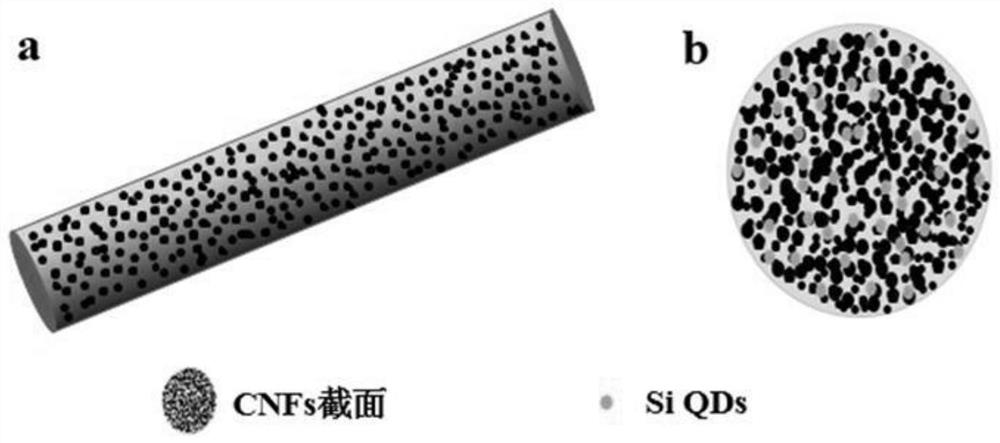

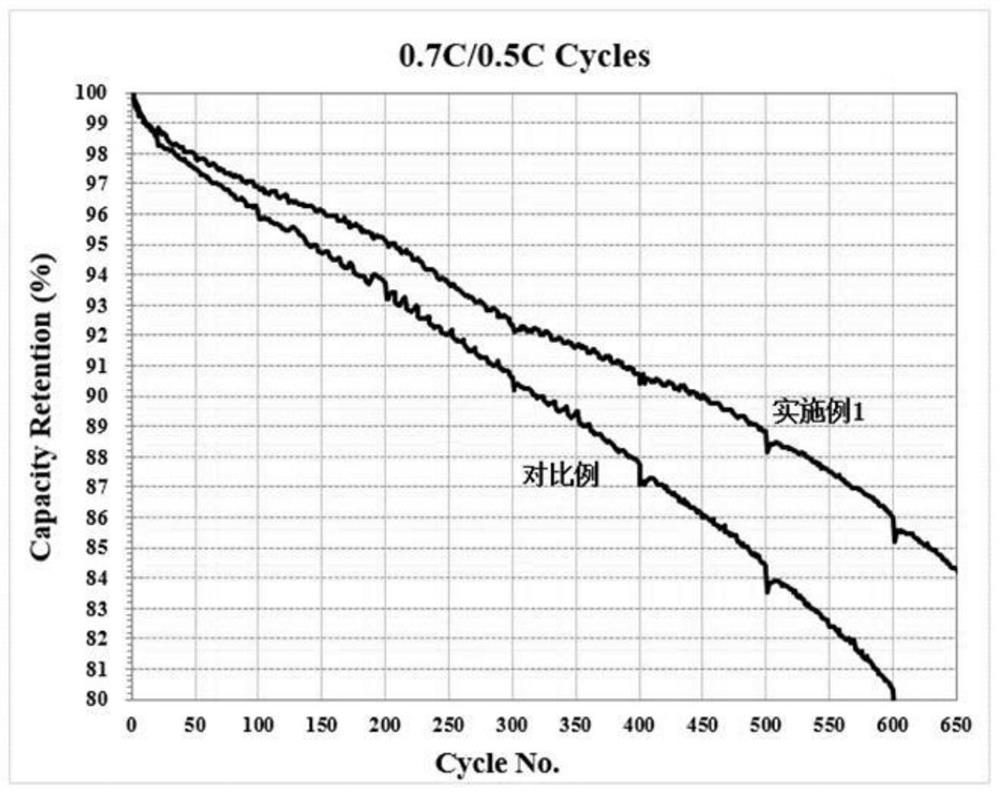

A conductive technology for lithium-ion batteries and negative electrodes, which is applied in battery electrodes, secondary batteries, and secondary battery repair/maintenance, etc. It can solve the problem of decreased rate performance and cycle performance, increased resistance to lithium ion diffusion, and increased coating volume, etc. problems, to achieve the effects of improving cycle performance, enhancing cooperative charge storage, and reducing overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

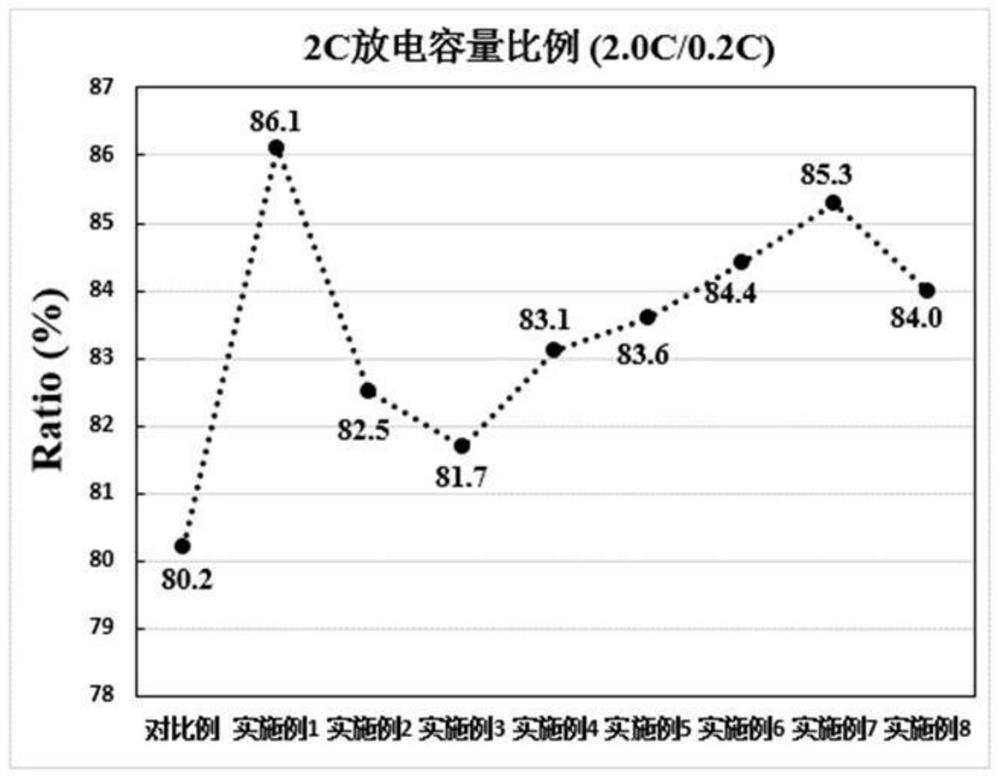

Examples

Embodiment 1

[0040]1) Disperse 1g of polyacrylonitrile, 3ml of N-trimethylsilimidazole, and 0.6g of citric acid into 12mL of dimethylformamide solvent, and stir the mixed solution for 4 hours to disperse;

[0041] 2) Inject the uniformly dispersed precursor solution into a plastic syringe connected with a stainless steel needle, the diameter of which is 0.9 mm;

[0042] 3) Adjust the injection rate of the syringe to 0.2mL / min through the precision propeller, and place an aluminum collector at about 15cm in the direction of the stainless steel needle to collect the prepared SiQDs / CNFs precursor;

[0043] 4) The prepared SiQDs / CNFs precursor was pre-oxidized in air for 1.5d, and then dried in a vacuum oven at 100°C for 10h;

[0044] 5) Place the dried precursor in a tube furnace with a protective atmosphere (argon:hydrogen = 95:5) for high-temperature carbonization. The high-temperature carbonization temperature is set to 700°C, the heating rate is 10°C / min, and the carbonization time is 8h...

Embodiment 2

[0049] 1) Disperse 1g of polyimide, 2ml of N-trimethylsilimidazole, and 0.4g of citric acid into 12mL of dimethylformamide solvent, and stir the mixed solution for 3 hours to disperse;

[0050] 2) Inject the uniformly dispersed precursor solution into a plastic syringe connected with a stainless steel needle, the diameter of which is 0.9mm;

[0051] 3) Adjust the injection rate of the syringe to 0.25mL / min through the precision propeller, and place an aluminum collector at about 15cm in the direction of the stainless steel needle to collect the prepared SiQDs / CNFs precursor;

[0052] 4) The prepared SiQDs / CNFs precursor was pre-oxidized in air for 2 days, and then dried in a vacuum oven at 100 °C for 10 hours;

[0053] 5) Place the dried precursor in a tube furnace with a protective atmosphere (argon:hydrogen = 95:5) for high-temperature carbonization. The high-temperature carbonization temperature is set to 700°C, the heating rate is 10°C / min, and the carbonization time is A...

Embodiment 3

[0058] 1) Disperse 1g of polyacrylonitrile, 2ml of aminopropyltrimethoxysilane, and 0.3g of ascorbic acid into 10mL of dimethylformamide solvent, and stir the mixed solution for 3 hours to disperse;

[0059] 2) Inject the uniformly dispersed precursor solution into a plastic syringe connected with a stainless steel needle, the diameter of which is 0.9mm;

[0060] 3) Adjust the injection rate of the syringe to 0.2mL / min through the precision propeller, and place an aluminum collector at about 15cm in the direction of the stainless steel needle to collect the prepared SiQDs / CNFs precursor;

[0061] 4) The prepared SiQDs / CNFs precursor was pre-oxidized in air for 1.5d, and then dried in a vacuum oven at 95°C for 10h;

[0062] 5) Place the dried precursor in a tube furnace with a protective atmosphere (argon: hydrogen = 95:5) for high-temperature carbonization. The high-temperature carbonization temperature is set to 800°C, the heating rate is 10°C / min, and the carbonization time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com