Preparation method and application of nitrogen-doped carbon nanotube-ruthenium dioxide composite material

A technology of nitrogen-doped carbon and ruthenium dioxide, which is applied in the field of nanomaterials, can solve the problems of easy agglomeration conductivity, lack of conductivity, high price of ruthenium dioxide, etc., and achieves the effects of high catalytic performance, simple method and excellent catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

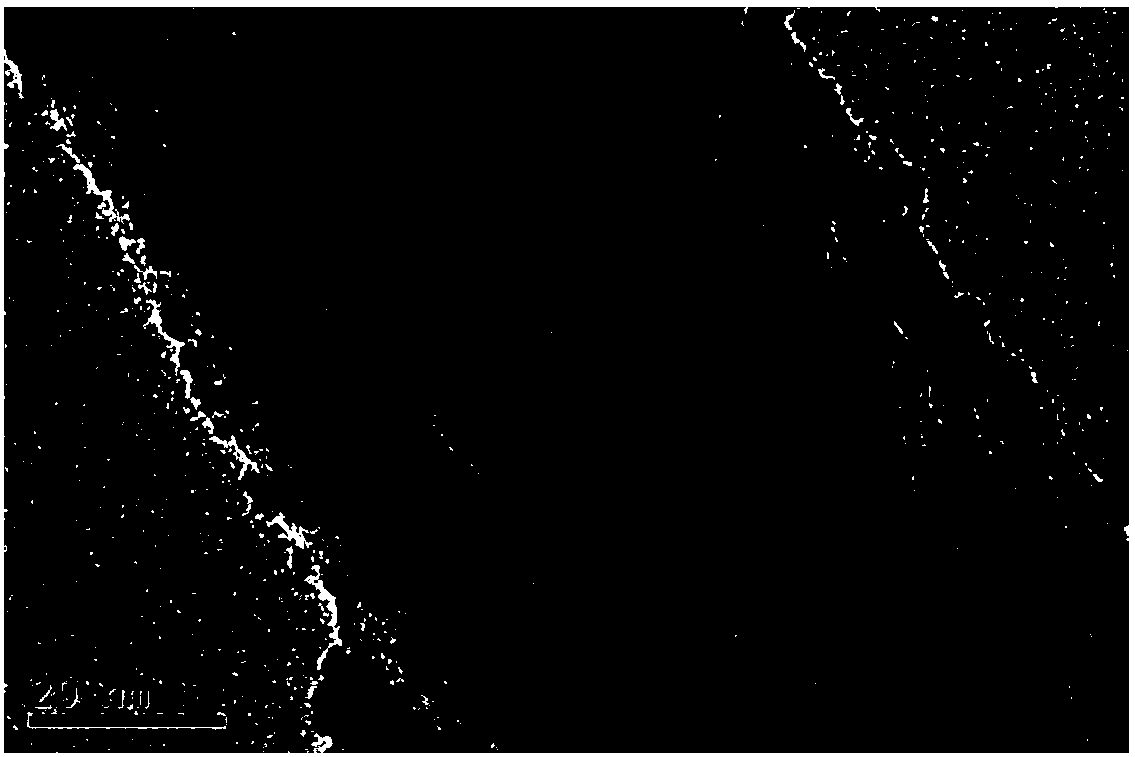

[0041] A preparation method of nitrogen-doped carbon nanotube-ruthenium dioxide composite material, comprising the following steps:

[0042] 1) Dissolve 0.4g hexaammonium trichloride ruthenium in 40ml ethanol to prepare hexaammonium trichloride ruthenium solution;

[0043] 2) Dissolve 0.22g of sodium hydroxide in 40ml of ethanol to obtain a sodium hydroxide solution;

[0044] 3) Take 7mL of nitrogen-doped carbon nanotubes with a solid content of 3wt% and mix them with hexammonium trichloride ruthenium solution (at this time, the mass ratio of nitrogen-doped carbon nanotubes to hexammonium trichloride ruthenium trichloride is 1:2 ), then add sodium hydroxide solution dropwise, control the reaction temperature to be 25°C, and stir at a rate of 600r / min, adjust and control the final pH value of the reaction system with sodium hydroxide solution to be 10;

[0045] 4) After reaching the final pH requirement of the reaction system, aging at a constant temperature of 70°C for 4 hour...

Embodiment 2

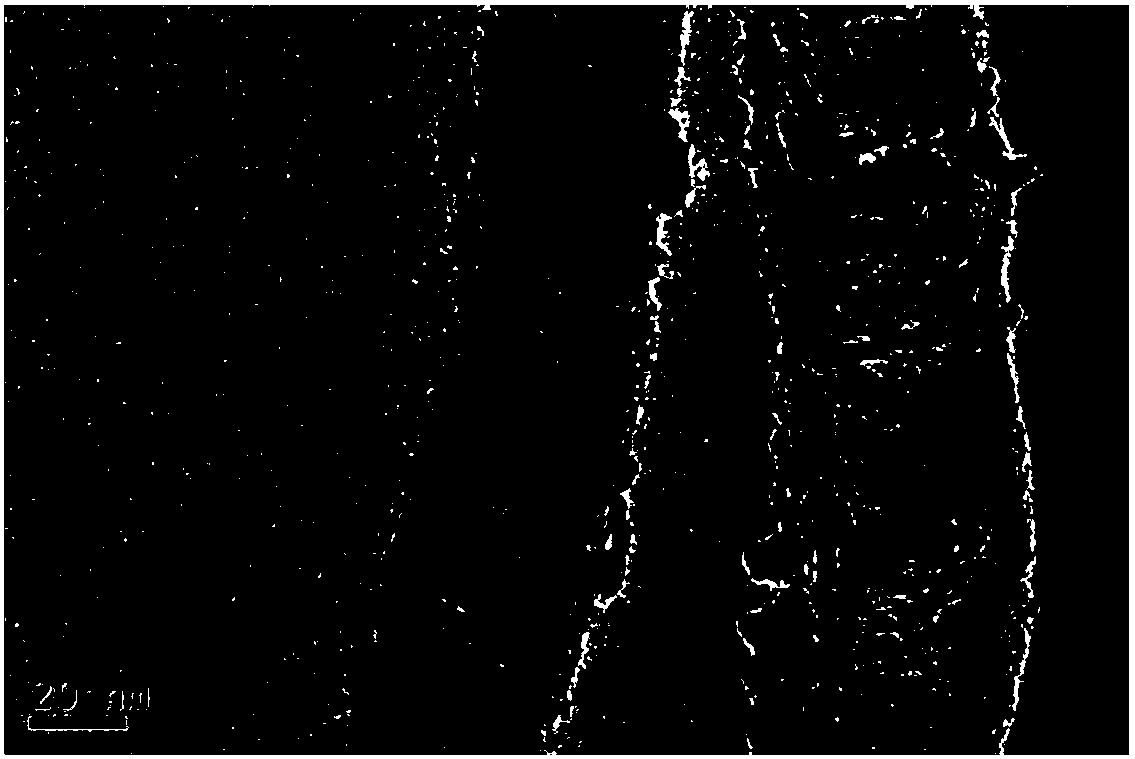

[0054] A preparation method of nitrogen-doped carbon nanotube-ruthenium dioxide composite material, comprising the following steps:

[0055] 1) 3g ruthenium trichloride is dissolved in 150ml water, makes ruthenium trichloride solution;

[0056] 2) Dissolve 1.50g of sodium hydroxide in 150ml of water to obtain a sodium hydroxide solution;

[0057] 3) Take 78.75mL of nitrogen-doped carbon nanotubes with a solid content of 3wt% and mix them with ruthenium trichloride solution (at this time, the mass ratio of nitrogen-doped carbon nanotubes to ruthenium trichloride is 1:2), and then dropwise Add sodium hydroxide solution, control the reaction temperature to 25°C, stir at a rate of 500r / min, adjust and control the final pH value of the reaction system to 10 with sodium hydroxide solution;

[0058] 4) After reaching the final pH value requirement of the reaction system, aging at a constant temperature of 60° C. for 5 hours;

[0059] 5) Wash the aged solution by centrifugation, put...

Embodiment 3

[0063] A preparation method of nitrogen-doped carbon nanotube-ruthenium dioxide composite material, comprising the following steps:

[0064] 1) Dissolve 1 g of ruthenium nitrosyl nitrate in 100 mL of deionized water / ethanol at a ratio of 1:1, and sonicate for 0.5 h;

[0065] 2) Dissolve 0.56g of sodium hydroxide in 100mL of deionized water / ethanol at a ratio of 1:1, and sonicate for 0.5h;

[0066] 3) Mix 78.75mL of nitrogen-doped carbon nanotube solution with a solid content of 3wt% and ruthenium nitrosyl nitrate solution (at this time, the mass ratio of nitrogen-doped carbon nanotubes to ruthenium nitrosyl nitrate is 1:2), Add sodium hydroxide solution dropwise to the mixed solution, control the reaction temperature to 35°C, and stir at a rate of 800r / min, adjust and control the final pH value of the reaction system to 11 with sodium hydroxide solution;

[0067] 4) After the final pH value requirement of the reaction system is reached, the temperature is raised to 90° C., an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com