Method for producing nano cerium oxide under supergravity action

A nano-cerium oxide, super-gravity technology, applied in chemical instruments and methods, nanotechnology, rare earth metal oxides/hydroxides, etc., can solve problems such as wide particle size distribution of products, non-polar solvents, etc., and achieve production process safety. The effect of improving reliability, saving production costs and improving environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

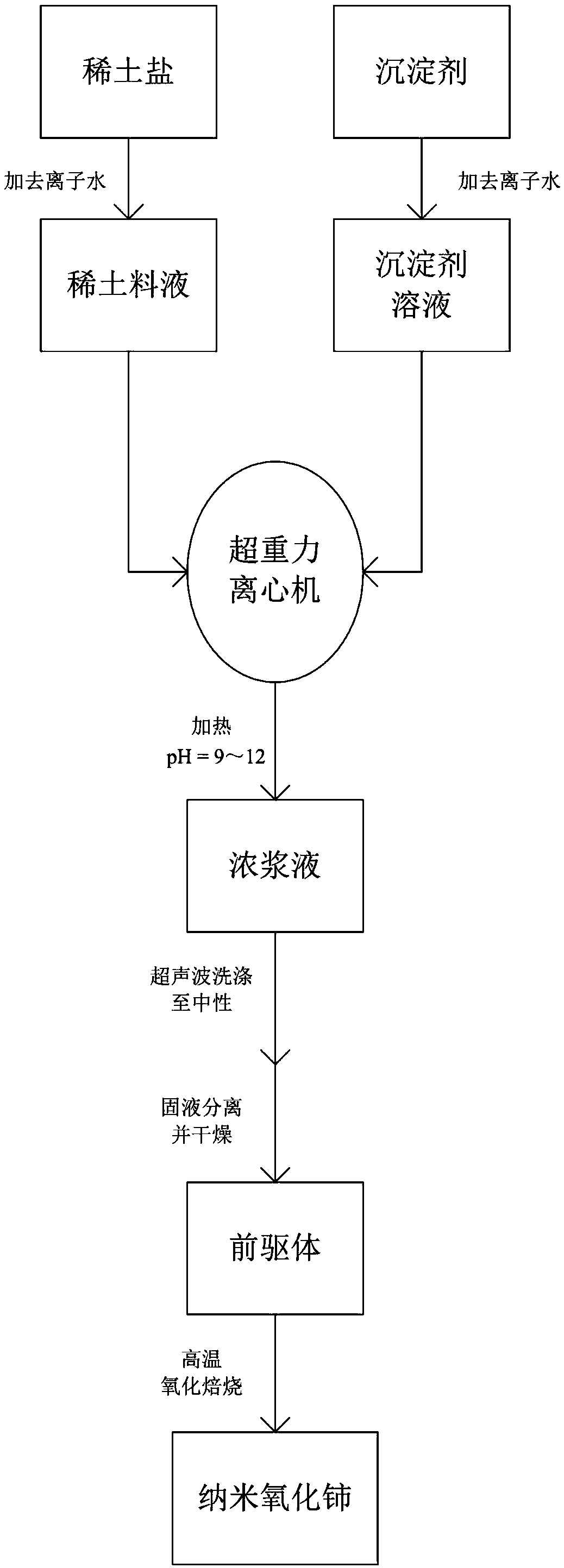

[0057] The method for producing nano cerium oxide by high gravity comprises the following steps:

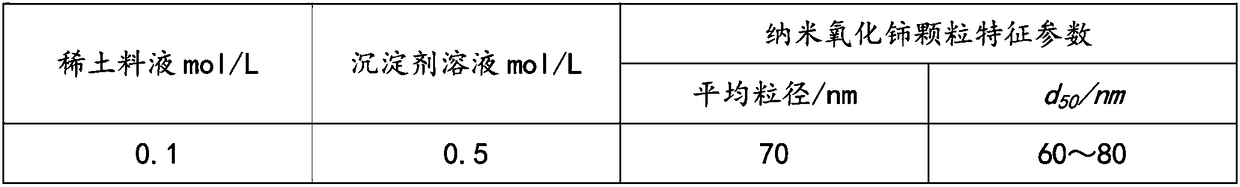

[0058] 1) Solution preparation: Dissolve cerium nitrate and urea completely with deionized water respectively to prepare a rare earth feed solution with a concentration of 0.1mol / L and a precipitant solution with a concentration of 0.5mol / L;

[0059] 2) Precursor preparation: continuously feed the rare earth material liquid and the precipitating agent solution into the supergravity centrifuge running at a stable speed of 500r / min, and keep the pH value of the mixed solution in the machine between 9 and 12 during the feeding process Precipitate for 0.3h under heating conditions at 40°C and centrifugation to obtain a thick slurry; wherein, the rare earth feed solution is added from the center of the rotor of the ultragravity centrifuge, and the precipitant solution is obtained from the ultragravity centrifuge The edge of the rotor is added, and the rare earth feed solution and prec...

Embodiment 2

[0065] The method for producing nano cerium oxide by high gravity comprises the following steps:

[0066] 1) Solution preparation: Dissolve cerium nitrate and urea completely with deionized water respectively to make a concentration of 0.2mol / L rare earth feed solution and a concentration of 1mol / L precipitant solution;

[0067]2) Precursor preparation: continuously feed the rare earth material liquid and the precipitant solution into the supergravity centrifuge running at a stable speed of 1500r / min, and keep the pH value of the mixed solution in the machine between 9 and 12 during the feeding process Precipitate for 3 hours under heating conditions at 100°C and centrifugation to obtain a thick slurry; wherein, the rare earth feed solution is added from the center of the rotor of the ultragravity centrifuge, and the precipitant solution is added from the center of the ultragravity centrifuge The edge of the rotor is added, and the rare earth feed solution and the precipitant ...

Embodiment 3

[0073] The method for producing nano cerium oxide by high gravity comprises the following steps:

[0074] 1) Solution preparation: Dissolve cerium nitrate and urea completely with deionized water respectively to prepare a rare earth feed solution with a concentration of 0.15mol / L and a precipitant solution with a concentration of 0.75mol / L;

[0075] 2) Precursor preparation: continuously feed the rare earth material liquid and the precipitant solution into the supergravity centrifuge running stably at a speed of 1000r / min, and keep the pH value of the mixed solution in the machine between 9 and 12 during the feeding process Precipitate for 2 hours under heating conditions at 70°C and centrifugation to obtain a thick slurry; wherein, the rare earth feed solution is added from the center of the rotor of the ultragravity centrifuge, and the precipitant solution is added from the center of the ultragravity centrifuge The edge of the rotor is added, and the rare earth feed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com