Preparation method of terephthaloyl chloride, terephthaloyl chloride and application as well as preparation method of p-phenylenediamine and p-phenylenediamine

A technology of terephthaloyl dichloride and p-phenylenediamine, which is applied in the field of chemical raw material preparation, can solve the problems of low purity of p-phenylenediamine, unstable product quality, and difficult waste disposal, and achieve good product stability and easy Implementation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

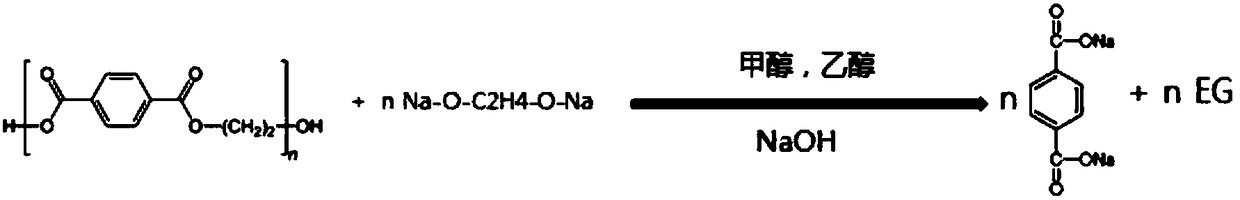

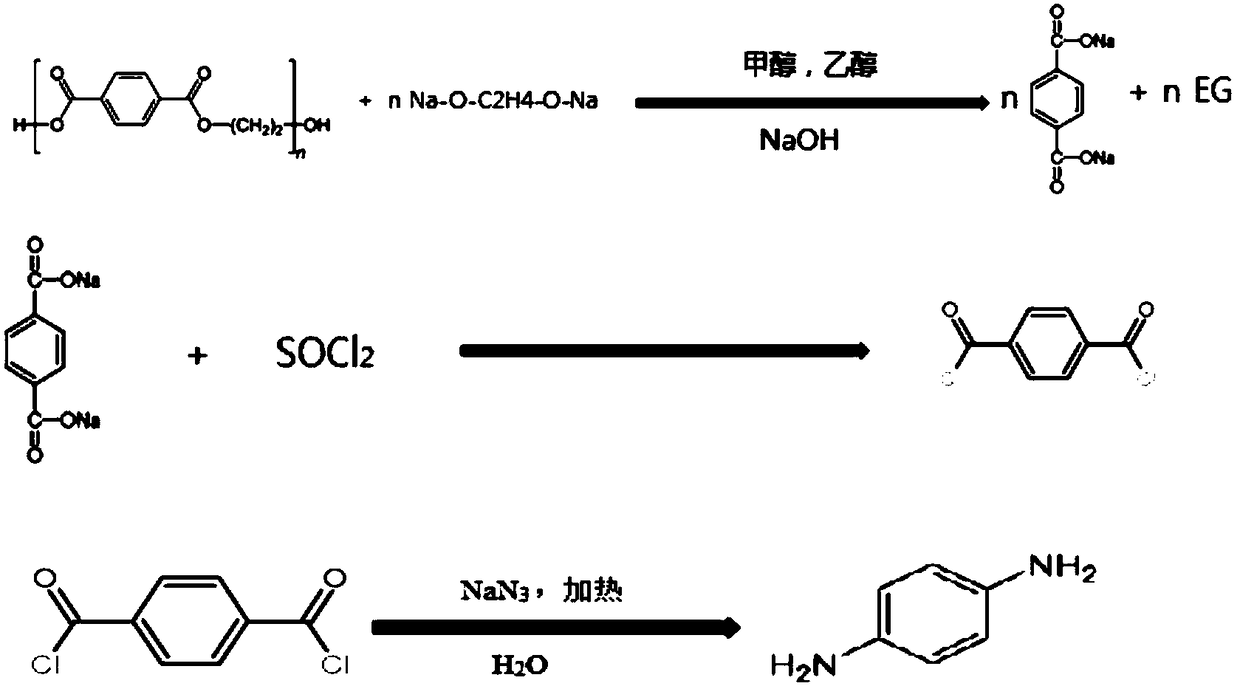

[0047]In the first aspect, in at least one embodiment, a kind of preparation method of terephthaloyl chloride is provided, using PET waste as starting material, comprising the following steps:

[0048] (a) PET waste and metal ethylene glycol salt are reacted in the presence of low-carbon alcohols to obtain metal terephthalate and ethylene glycol;

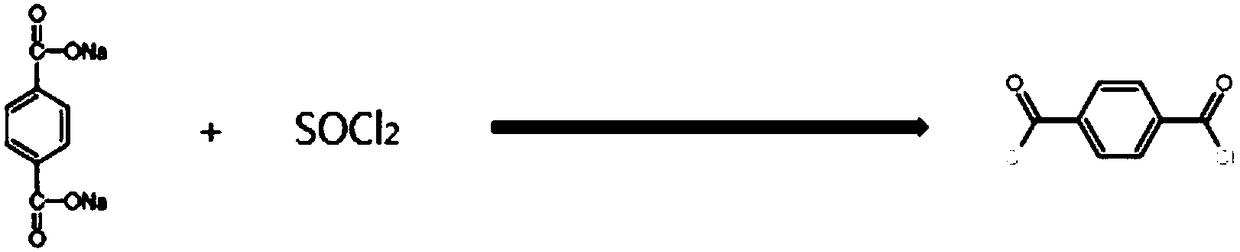

[0049] (b) react the metal salt of terephthalic acid with a chlorinating agent to obtain terephthaloyl chloride.

[0050] According to the present invention, PET is Polyethyleneterephthalate, and its Chinese name is polyethylene terephthalate; it is a common resin in life.

[0051] In order to reduce the most important preparation cost, the present invention does not use the existing high-purity and expensive terephthalic acid as the starting material, but creatively proposes to use the extremely cheap PET waste discarded as garbage as the starting material to prepare Terephthaloyl chloride (TPC, terephthaloyl chloride). The inven...

Embodiment 1

[0110] A kind of preparation method of terephthaloyl chloride, take PET waste as starting raw material, comprises the following steps:

[0111] (a) Mix 80g of waste PET bottle fragments, 5g of waste PE bottle fragments, 5g of waste PP bottle fragments, 30mL of sodium ethylene glycol, 50g of sodium hydroxide, and 500mL of methanol for reaction. Reflux, the reaction pressure is 1×10 5 Pa was reacted for about 1 hour to obtain a white precipitate of sodium terephthalate and ethylene glycol. After the reaction, filter the reaction solution with a 20-mesh sieve to filter out the PE and PP bottle fragments; wash the filtered PE and PP fragments with methanol, dry them and weigh them. The result is the same as the initial weight; furthermore, it shows that only waste PET bottles A hydrolysis reaction was carried out.

[0112] The reaction solution after removing PE and PP fragments was filtered to filter out the white precipitate sodium terephthalate, and then the obtained white pr...

Embodiment 2

[0121] A kind of preparation method of terephthaloyl chloride, take PET waste as starting raw material, and the difference of embodiment 1 is:

[0122] Replace sodium ethylene glycol and sodium hydroxide in embodiment 1 with potassium ethylene glycol and potassium hydroxide, and all the other are identical with embodiment 1.

[0123] The chromatographic content of the terephthaloyl chloride prepared in this example was 99.91%, and the yield was 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com