Elastic sand-carrying fracturing fluid, thickener for the fracturing fluid and preparation method thereof

A thickening agent and fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as large demand for surfactants, high requirements for construction equipment, and unfavorable environmental protection, and achieve construction results. The effect of obvious, low equipment requirements and fast dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

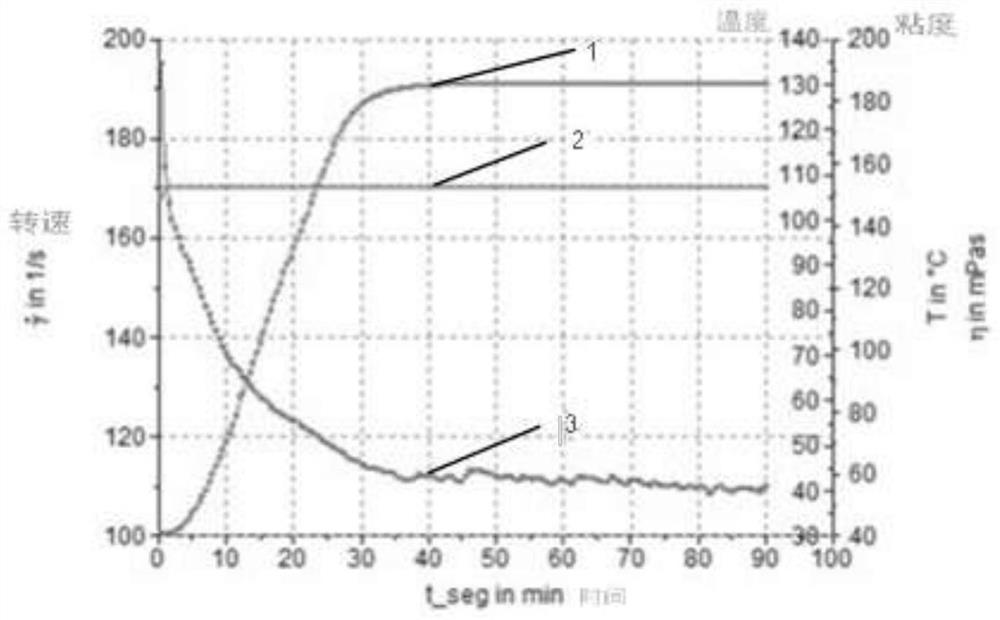

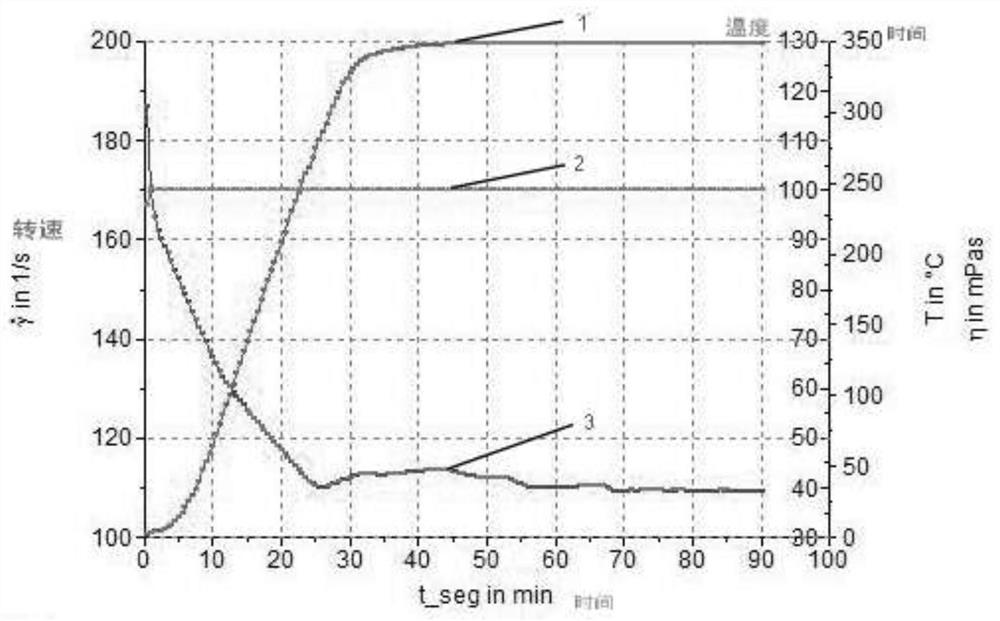

Image

Examples

preparation example Construction

[0044] Its concrete preparation method is as follows:

[0045] 1. Preparation of thickener for elastic sand-carrying fracturing fluid

[0046] Dissolve analytically pure acrylamide in water, add octadecyltrimethylammonium bromide, potassium persulfate, and caustic soda under stirring, heat to 70°C, and then slowly add diethylene glycol distearate in sequence , tripolyglycerol diisostearate, sodium tetradecyl carboxylate, fatty acid amidopropyl dimethylamine, tertiary amino alcohol, fully reacted for 2 hours, passed nitrogen gas at 80°C to remove excess bromine to stop the reaction, and The obtained product is continuously passed through nitrogen to crystallize, and the crystallized product is dried and granulated to obtain the thickener.

[0047] 2. Preparation of elastic sand-carrying fracturing fluid

[0048] The preparation method in the laboratory of the elastic sand-carrying fracturing fluid provided by the invention is as follows:

[0049] In the laboratory, add water...

Embodiment 1

[0053] A thickener for elastic sand-carrying fracturing fluid, the preparation raw materials of the thickener include the following components in parts by weight: 0.5 part of acrylamide; 1 part of octadecyltrimethylammonium bromide; 0.05 parts of potassium persulfate; 0.005 parts of alkali; 1 part of diethylene glycol distearate; 0.5 parts of tripolyglycerol diisostearate; 0.2 parts of sodium tetradecyl carboxylate; 0.2 parts of amines; 0.2 parts of tertiary amino alcohols.

[0054] A preparation method for a thickener for elastic sand-carrying fracturing fluid, comprising the steps of:

[0055] A. Dissolve acrylamide in water to obtain an acrylamide solution:

[0056] B. In a stirring state, add octadecyltrimethylammonium bromide, potassium persulfate and caustic soda to the acrylamide solution and mix well to obtain an intermediate solution;

[0057] C. Add diethylene glycol distearate, triglyceryl diisostearate, sodium tetradecyl carboxylate, fatty acid amidopropyl dimeth...

Embodiment 2

[0062] A thickener for elastic sand-carrying fracturing fluid, the preparation raw materials of the thickener include the following components in parts by weight: 1.5 parts of acrylamide; 5 parts of octadecyltrimethylammonium bromide; 0.15 parts of potassium persulfate; 0.015 parts of alkali; 5 parts of diethylene glycol distearate; 1.5 parts of tripolyglycerol diisostearate; 0.8 parts of sodium tetradecyl carboxylate; 1.5 parts of amine; 0.8 parts of tertiary amino alcohol.

[0063] A preparation method for a thickener for elastic sand-carrying fracturing fluid, comprising the steps of:

[0064] A. Dissolve acrylamide in water to obtain an acrylamide solution:

[0065] B. In a stirring state, add octadecyltrimethylammonium bromide, potassium persulfate and caustic soda to the acrylamide solution and mix well to obtain an intermediate solution;

[0066] C. Add diethylene glycol distearate, triglyceryl diisostearate, sodium tetradecyl carboxylate, fatty acid amidopropyl dimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com