Cobalt sulfide/carbon fiber compound and preparation method and application thereof

A carbon fiber and composite technology, applied in the field of cobalt sulfide/carbon fiber composites and its preparation, can solve the problems of poor electrical conductivity of materials, achieve the effects of reducing expansion stress, simplifying the preparation process, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

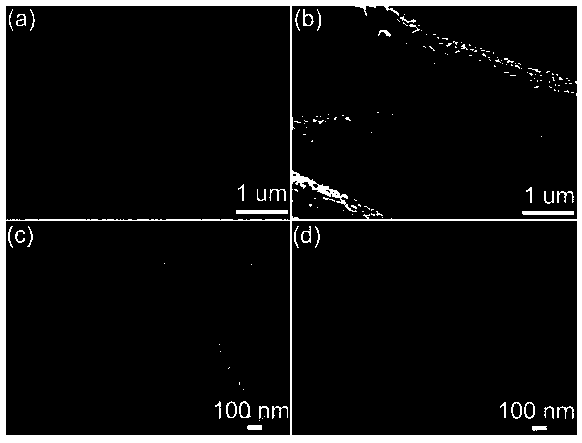

Image

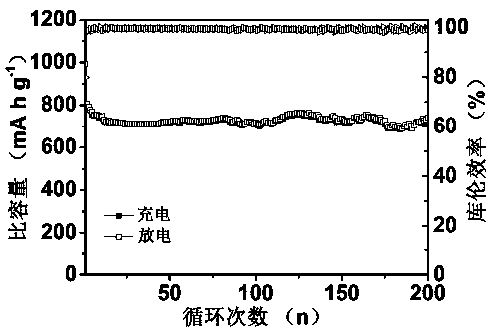

Examples

Embodiment 1

[0045] Add 1.4g of polyacrylonitrile into 10mL of N,N-dimethylformamide solution, stir until clear, and record it as solution A. Dissolve 1.164g of cobalt nitrate hexahydrate in 5mL of N,N-dimethylformamide solution, stir until clear, and record it as solution B. Mix the clear A and B solutions together and continue to stir for 24h. Electrospinning is performed on the mixed solution to obtain polyacrylonitrile / cobalt nitrate composite membrane. Among them, electrospinning parameters: voltage 15.6 kV, liquid supply rate 0.8 mL / h, drum speed 700 r / min, needle size 21º, distance from needle to drum 28 cm, temperature 40 °C, humidity 10%.

[0046] The obtained polyacrylonitrile / cobalt nitrate composite membrane was placed in a methanol solution containing 0.9852g 2-methylimidazole for 24 hours to obtain polyacrylonitrile / cobalt nitrate@metal organic framework (ZIF-67). The obtained polyacrylonitrile / cobalt nitrate@metal organic framework (ZIF-67) was dried in a vacuum oven at 70...

Embodiment 2

[0055] Add 1.4g of polyacrylonitrile into 10mL of N,N-dimethylformamide solution, stir until clear, and record it as solution A. Dissolve 0.873g of cobalt nitrate hexahydrate in 5mL of N,N-dimethylformamide solution, stir until clear, and record it as solution B. Mix the clear A and B solutions together and continue to stir for 24h. Electrospinning is performed on the mixed solution to obtain polyacrylonitrile / cobalt nitrate composite membrane. Among them, electrospinning parameters: voltage 15.6 kV, liquid supply rate 0.8 mL / h, drum speed 700 r / min, needle size 21º, distance from needle to drum 28 cm, temperature 40 °C, humidity 10%.

[0056] The obtained polyacrylonitrile / cobalt nitrate composite membrane was placed in a methanol solution containing 0.9852g 2-methylimidazole for 24 hours to obtain polyacrylonitrile / cobalt nitrate@metal organic framework (ZIF-67). The obtained polyacrylonitrile / cobalt nitrate@metal organic framework (ZIF-67) was dried in a vacuum oven at 70...

Embodiment 3

[0060] Add 1.4g of polyacrylonitrile into 10mL of N,N-dimethylformamide solution, stir until clear, and record it as solution A. Dissolve 1.455g of cobalt nitrate hexahydrate in 5mL of N,N-dimethylformamide solution, stir until clear, and record it as solution B. Mix the clear A and B solutions together and continue to stir for 24h. Electrospinning is performed on the mixed solution to obtain polyacrylonitrile / cobalt nitrate composite membrane. Among them, electrospinning parameters: voltage 15.6 kV, liquid supply rate 0.8 mL / h, drum speed 700 r / min, needle size 21º, distance from needle to drum 28 cm, temperature 40 °C, humidity 10%.

[0061] The obtained polyacrylonitrile / cobalt nitrate composite membrane was placed in a methanol solution containing 0.9852g 2-methylimidazole for 24 hours to obtain polyacrylonitrile / cobalt nitrate@metal organic framework (ZIF-67). The obtained polyacrylonitrile / cobalt nitrate@metal organic framework (ZIF-67) was dried in a vacuum oven at 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com