Electrolyte of high-voltage lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as increasing battery internal resistance, deteriorating cycle performance, and capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The boron-containing additive lithium bisoxalate borate (LiBOB) has good film-forming properties. It can not only form a layer of SEI film on the graphite negative electrode, but also form a protective film on the surface of the positive electrode material to prevent the ester electrolyte and The positive electrode material contact at high potential is oxidized, slowing down the capacity loss of lithium-ion batteries during cycling.

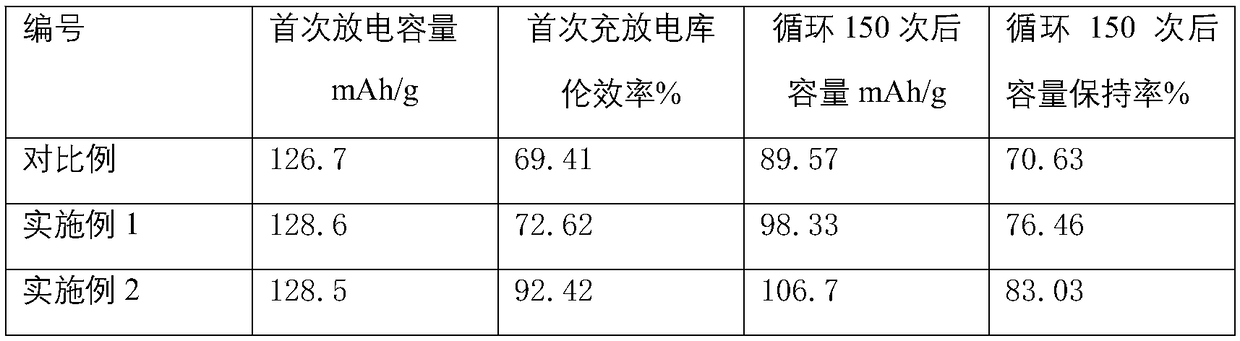

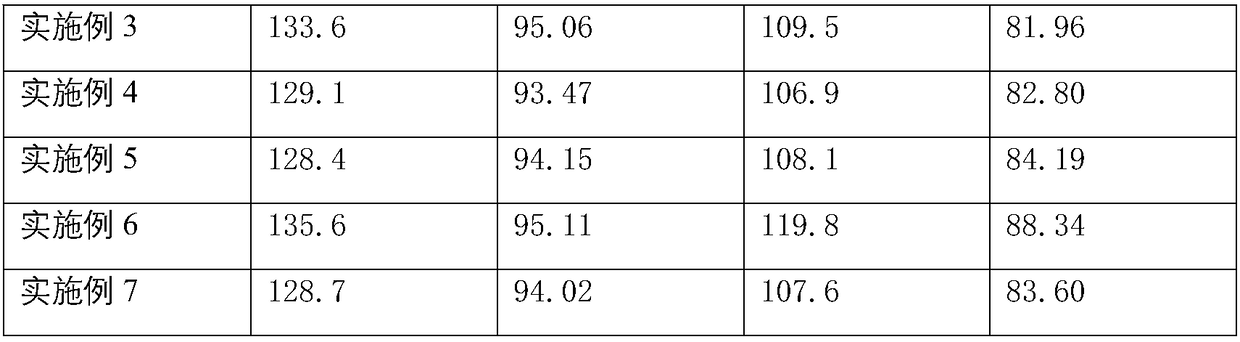

[0025] (2) In order to test the influence of a small amount of boron-containing additive lithium bisoxalate borate (LiBOB) on the cycle performance of lithium-ion batteries under high voltage conditions, LiBOB with a mass fraction of 1% was added to the conventional electrolyte configured in the comparative example and applied The positive electrode material is lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 , the negative electrode material is artificial graphite, and the diaphragm is a Celgard 2400 high-voltage lithium-ion batte...

Embodiment 2

[0028] (1) Because of its nucleophilic group-CN, dinitrile additives can be used to eliminate HF generated during lithium-ion battery cycling and protect the electrodes. In addition, it will also interact with PF 5 The reaction occurs to eliminate the by-product PF 5 In this way, the oxidative decomposition film-forming reaction of the ester solvent is suppressed, thereby improving the cycle performance of the high-voltage lithium-ion battery.

[0029] (2) In order to test the impact of a small amount of dinitrile additives on the cycle performance of lithium-ion batteries under high voltage conditions, succinonitrile with a mass fraction of 1% is added to the conventional electrolyte configured in the comparative example and applied to the positive electrode material as Lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 , the negative electrode material is artificial graphite, and the diaphragm is a Celgard 2400 high-voltage lithium-ion battery.

[0030] (3) The prepared ...

Embodiment 3

[0032] (1) In order to test the influence of different types of dinitrile additives on the cycle performance of lithium-ion batteries under high voltage conditions, adiponitrile with a mass fraction of 1% was added to the conventional electrolyte configured in the comparative example and applied to the positive electrode material lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 , the negative electrode material is artificial graphite, and the diaphragm is a Celgard 2400 high-voltage lithium-ion battery.

[0033] (2) Perform charge and discharge tests on the prepared lithium-ion battery on the blue electric test system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com