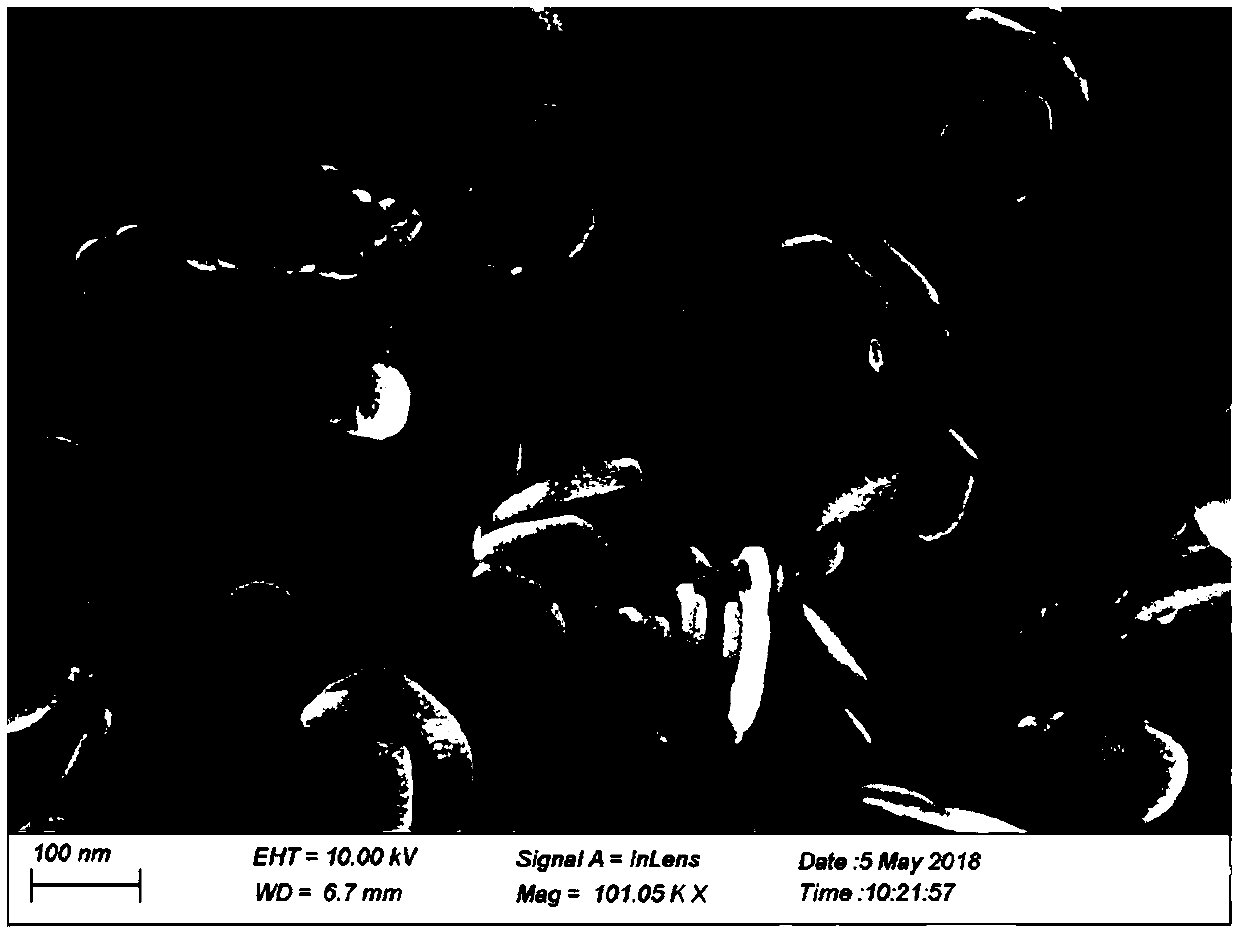

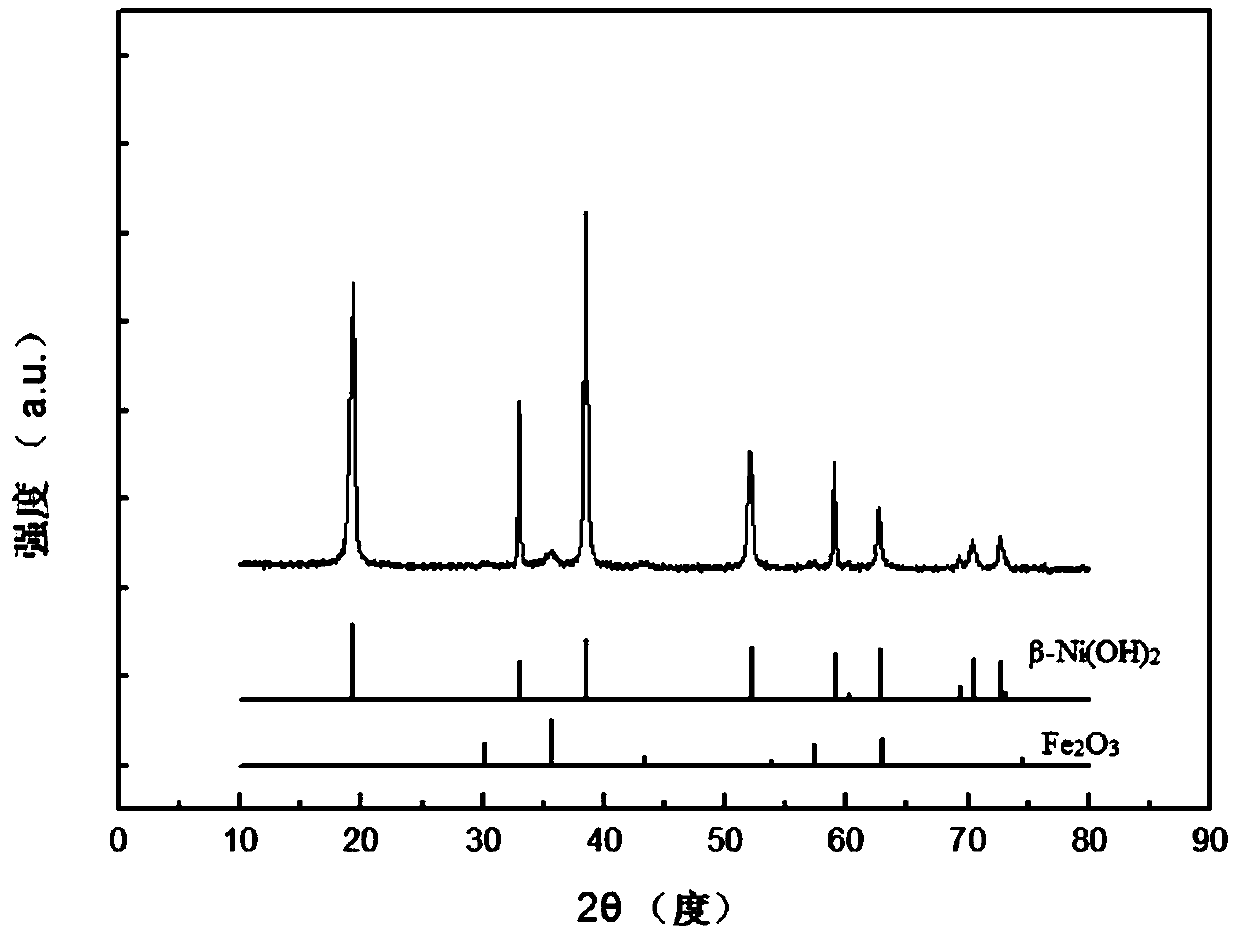

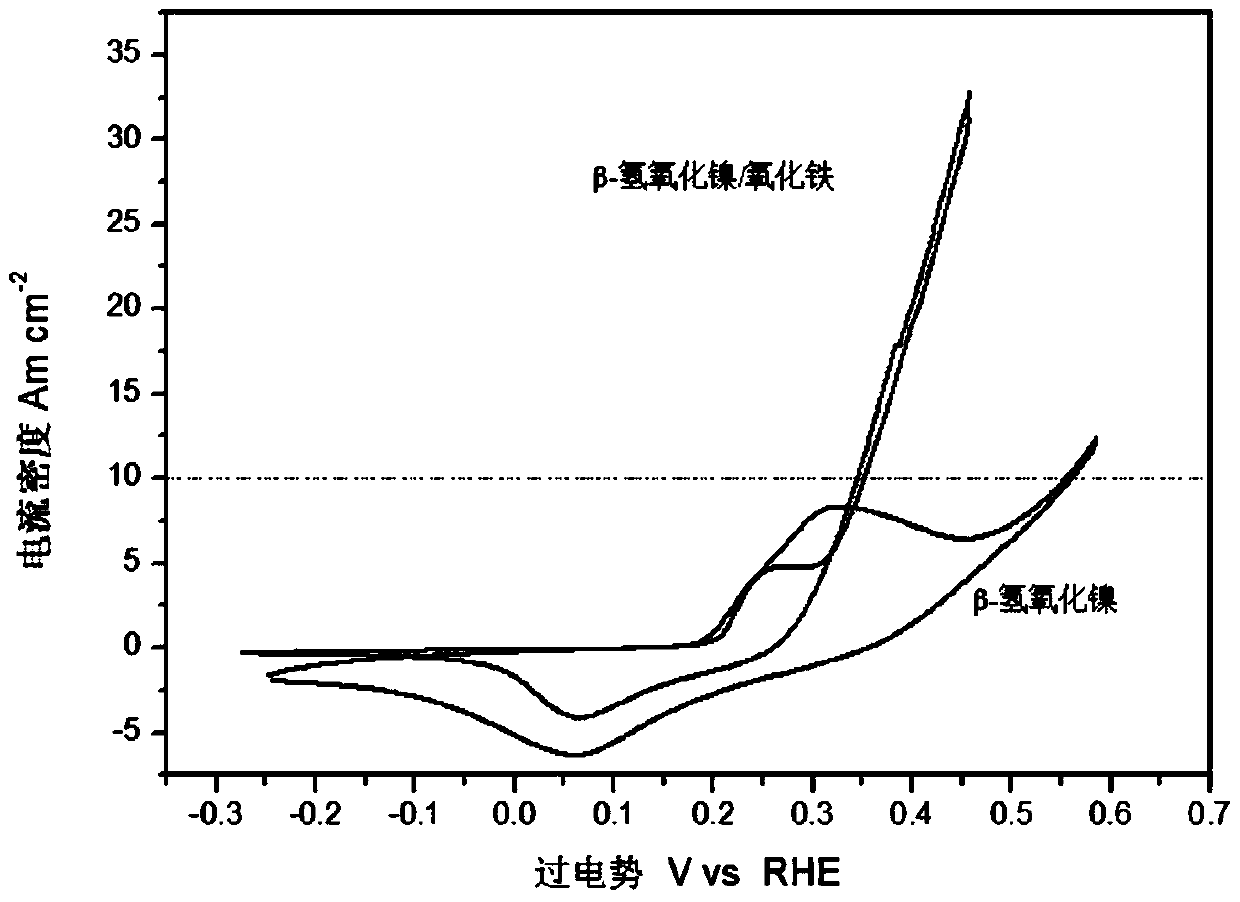

Beta-nickel hydroxide/iron oxide ultrathin nano-sheet and preparation method thereof

A technology of iron oxide nanometer and nickel hydroxide, which is applied in the field of nanomaterials, can solve the problems of complexity and difficult to control film thickness, and achieve the effect of uniform size distribution, easy control and simplified process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of β-nickel hydroxide / iron oxide ultrathin nanosheets, comprising the following steps:

[0035] S1), the soluble nickel salt NiSO of 1.6mmol 4 ·6H 2 O was dissolved in 20mL of deionized water to form a water-soluble nickel salt solution, then 0.0100g of ferrihydrite was added to the nickel sulfate aqueous solution, and stirred for 0.5h, so that the ferrihydrite could fully absorb divalent nickel ions;

[0036] S2), then dissolving 3.2 mmol of sodium hydroxide in 20 mL of deionized water to form an aqueous sodium hydroxide solution, then adding the aqueous sodium hydroxide solution to the mixed solution in step S1), stirring well to obtain a precursor solution, And adjust the pH value of the mixed solution by sodium hydroxide aqueous solution;

[0037] S3), heating the precursor solution to 180° C., and performing a hydrothermal reaction for 9 hours;

[0038] S4), naturally cool to room temperature after the reaction, centrifuge the cooled sample,...

Embodiment 2

[0042] A preparation method of β-nickel hydroxide / iron oxide ultrathin nanosheets, comprising the following steps:

[0043] S1), the soluble nickel salt NiSO of 1.6mmol 4 ·6H 2 O was dissolved in 20mL of deionized water to form a water-soluble nickel salt solution, then 0.0100g of ferrihydrite was added to the nickel sulfate aqueous solution, and stirred for 0.5h, so that the ferrihydrite could fully absorb divalent nickel ions;

[0044] S2), then dissolving 1.6 mmol of sodium hydroxide in 20 mL of deionized water to form an aqueous sodium hydroxide solution, then adding the aqueous sodium hydroxide solution to the mixed solution in step S1), and fully stirring for 10 min to obtain a precursor solution, And adjust the pH value of the mixed solution by sodium hydroxide aqueous solution;

[0045] S3), heating the precursor solution to 120° C., performing a hydrothermal reaction for 8 hours, and obtaining β-nickel hydroxide / iron oxide nanosheets;

[0046] S4), naturally cool t...

Embodiment 3

[0049] A preparation method of β-nickel hydroxide / iron oxide ultrathin nanosheets, comprising the following steps:

[0050] S1), the soluble nickel salt NiSO of 1.6mmol 4 ·6H 2 O was dissolved in 20mL of deionized water to form a water-soluble nickel salt solution, then 0.0100g of ferrihydrite was added to the nickel sulfate aqueous solution, and stirred for 0.5h, so that the ferrihydrite could fully absorb divalent nickel ions;

[0051] S2), then dissolving 3.2 mmol of sodium hydroxide in 20 mL of deionized water to form an aqueous sodium hydroxide solution, then adding the aqueous sodium hydroxide solution to the mixed solution in step S1), and fully stirring for 10 min to obtain a precursor solution, And adjust the pH value of the mixed solution by sodium hydroxide aqueous solution;

[0052] S3), heating the precursor solution to 120° C., performing a hydrothermal reaction for 8 hours, and obtaining β-nickel hydroxide / iron oxide nanosheets;

[0053] S4), naturally cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com