Nano-modified thermoelectric mortar and preparation method thereof, as well as intelligent cathodic protection and deterioration self-monitoring system for thermoelectric structure and preparation method thereof

A nano-modification and nano-technology, applied in the direction of electrochemical variables of materials, can solve the problems such as hindering the hydration of mortar and cement, increasing the unsafe factors of the structure, and unable to overcome the difficulty of construction with a small protective current and a long life of the anode material. Intrinsic strength and impermeability durability, alleviating sulfate corrosion problems, and ensuring the effect of intrinsic protective functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

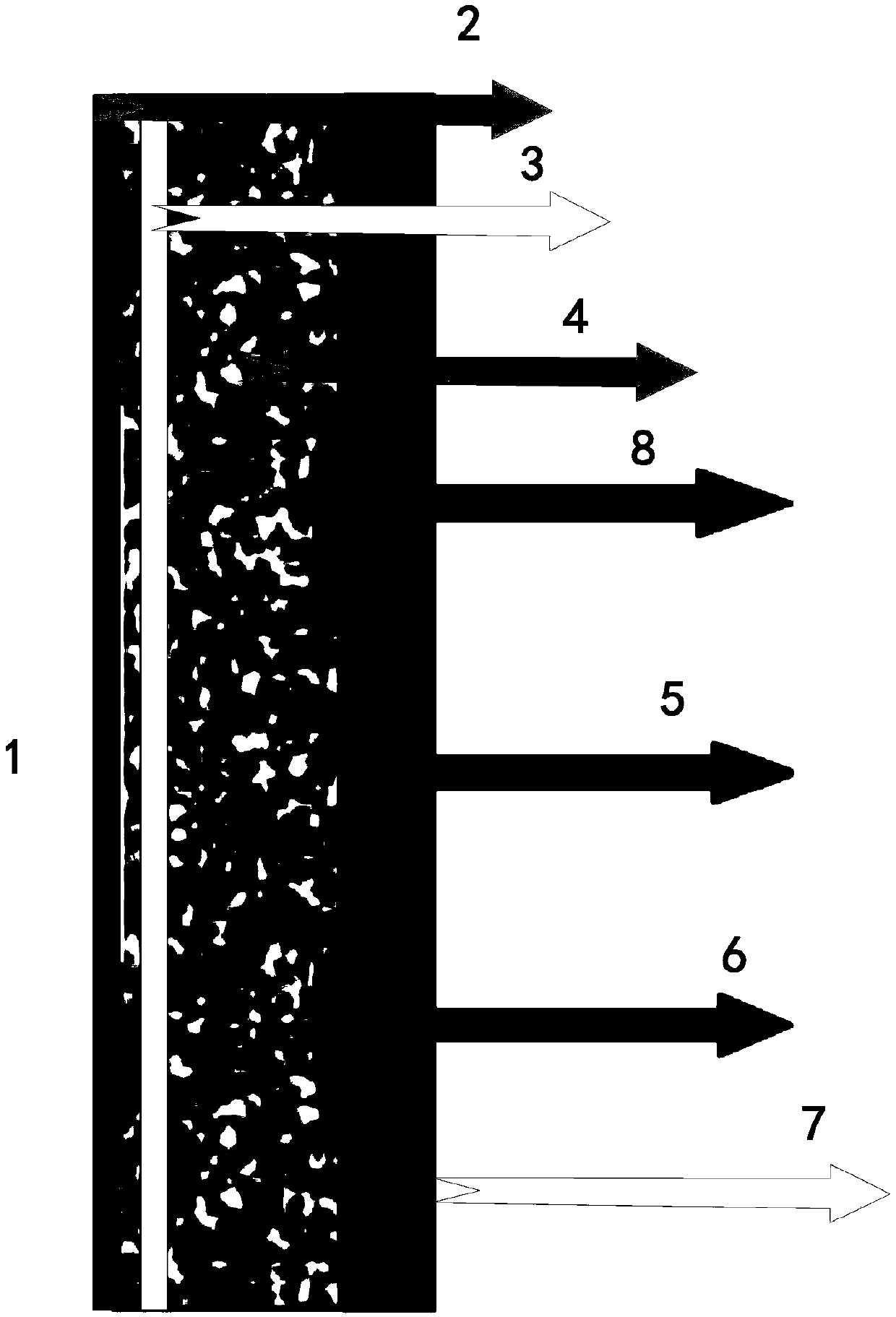

[0031] Such as figure 1 As shown, an intelligent cathodic protection and degradation self-monitoring system for a thermoelectric structure includes a thermoelectric structure, a mesh bottom electrode 2, a titanium mesh anode 3 and a carbon fiber cloth top electrode 5 arranged in sequence, and the mesh bottom electrode 2 is laid on The surface layer of the thermoelectric structure concrete base surface 1, the mesh bottom electrode 2 and the titanium mesh anode 3, and the titanium mesh anode 3 and the carbon fiber cloth top electrode 5 are respectively sandwiched with a nano-modified thermoelectric mortar layer 4, and the carbon fiber cloth top electrode The surface layer of the electrode 5 is provided with a waterproof coating 6 and a signal marking coating 7 in sequence. The local concave and convex parts in the nano-modified thermoelectric mortar layer 4 are repaired and smoothed with cement-based permeable crystalline material 8 .

[0032] When the nano-modified thermoelect...

Embodiment 2

[0047] The preparation process and structure of the nano-modified thermoelectric mortar are the same as in Example 1, except that:

[0048] The nano-conductive and thermoelectric components used are CNF and nano-Bi respectively. 2 Te 3 The concrete superplasticizer used is naphthalene sulfonate FDN; the cement is sulfoaluminate cement; the mineral admixture is S105 grade ultrafine mineral powder, and the dosage is 8% of the cement consumption; The corresponding nano-modified thermoelectric mortar is prepared by compaction process (pressure 15MPa, pressure holding 15-90min), and cured to 7d age.

[0049] Characterization of CNF-Hybrid Nano-Bi by Solution Conductivity Method 2 Te 3 CNF, Bi in the dispersion 2 Te 3 Uniform dispersion and stable state, the conductivity of the solution before and after dispersion is 105.20S / cm, 1.28S / cm respectively; CNF / Bi is measured with a cement coagulation time tester 2 Te 3 The initial and final setting times of the modified thermoelec...

Embodiment 3

[0058] The preparation process and structure of the nano-modified thermoelectric mortar are the same as in Example 1, except that:

[0059] The graphene conductive paste is used, and the thermoelectric component used is nano-Cu 2 O, the mineral admixture is condensed silica fume, and the dosage is 5% of the cement consumption.

[0060] Characterization of graphene-hybrid nano-Cu by solution conductivity method etc. 2 Graphene, Cu in O dispersion 2 O is uniformly dispersed and stable, and the conductivity of the solution before and after dispersion is 82.63S / cm and 0.925S / cm respectively; the graphene-mixed Cu is measured with a mortar coagulation time tester 2 The initial and final coagulation times of O-modified thermoelectric mortar slurry were 70min and 240min, respectively, indicating that graphene, Cu 2 The introduction of O prolongs the setting time of mortar, but has little effect. Testing graphene hybrid Cu with a universal material testing machine 2 The flexural ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com