Preparation method of modified polysaccharide hydrogel and prepared modified polysaccharide hydrogel

A hydrogel and polysaccharide technology, applied in the field of hydrogel preparation, can solve the problems of poor biocompatibility and harsh synthesis conditions, achieve high equilibrium water content, simple reaction conditions, and improve biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention provides a kind of preparation method of modified polysaccharide hydrogel, comprising the following steps:

[0038] (1) Preparation of double bond modified polysaccharide:

[0039] Mix 0.5g of hyaluronic acid and water evenly in proportion to a concentration of 3wt%, under magnetic stirring, add 100μL of triethylamine, 0.47g of tetrabutylammonium bromide, 3.2mL of glycidyl methacrylate, and react for 24 hours , followed by dialysis in 0.1M sodium chloride and deionized water for 12 hours, and lyophilized to obtain double bond modified hyaluronic acid (HAGMA);

[0040] (2) Preparation of zwitterionic thiol polymer (CB-SH):

[0041] Dissolve 0.5 g of carboxybetaine methyl methacrylate (CBMA) and 40 mg of N,N'-bis(acryloyl) cystamine (BAC) in a mixed solvent of 4 ml of water and ethanol, then add 16 mg of ammonium persulfate, 20 μL N,N,N',N'-tetramethylethylenediamine, reacted for 24h, dialyzed the reaction product in deionized water for three days to remov...

Embodiment 2

[0047] The invention provides a kind of preparation method of modified polysaccharide hydrogel, comprising the following steps:

[0048] (1) The preparation of the double bond modified polysaccharide is the same as in Example 1 step (1);

[0049] (2) The preparation of the zwitterionic mercapto polymer (CB-SH) is the same as in Example 1 step (2);

[0050] (3) Preparation of "click" chemical hydrogel:

[0051] Dissolve 50mg HAGMA in 1ml PBS (PH=7.2) buffer solution, stir well, and set aside; Dissolve 0.1g CB-SH in 1ml PBS (PH=7.2) buffer solution, stir well, set aside; Take a certain amount of two kinds of Mix the mother liquor evenly according to the ratio of double bond-mercapto group of 2:1, put it in a constant temperature water bath at 37°C, and gel can be formed spontaneously within 1 hour.

Embodiment 3

[0053] The invention provides a kind of preparation method of modified polysaccharide hydrogel, comprising the following steps:

[0054] (1) The preparation of the double bond modified polysaccharide is the same as in Example 1 step (1);

[0055] (2) The preparation of the zwitterionic mercapto polymer (CB-SH) is the same as in Example 1 step (2);

[0056] (3) Preparation of "click" chemical hydrogel:

[0057] Dissolve 50mg HAGMA in 1ml PBS (PH=7.2) buffer solution, stir well, and set aside; Dissolve 0.1g CB-SH in 1ml PBS (PH=7.2) buffer solution, stir well, set aside. Take a certain amount of two kinds of mother liquors, mix them evenly according to the ratio of double bond-mercapto group of 1:2, put them in a constant temperature water bath at 37°C, and gel can be formed spontaneously within 1 hour.

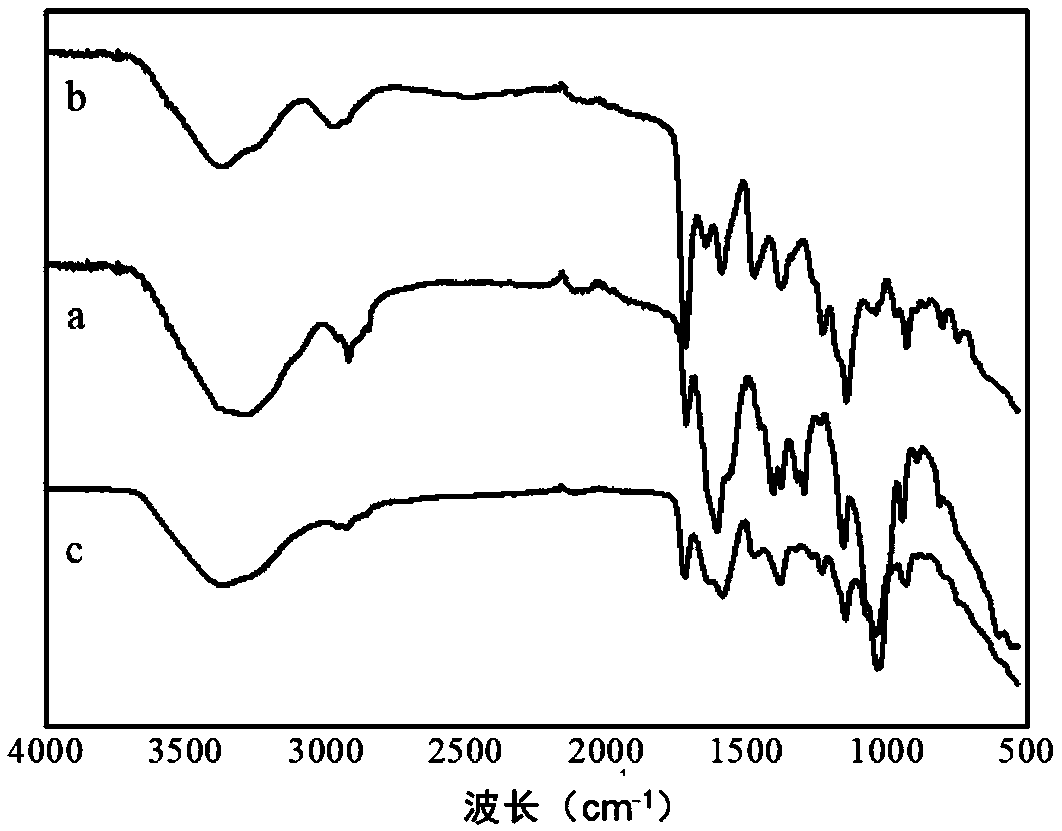

[0058] In order to further illustrate the performance of the hydrogel prepared by the present invention, due to limited space, only Example 1 is used as an example to constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com