Method for preparing machine-made charcoal from needle mushroom residues

A technology of Flammulina velutipes mushroom residue and machine-made charcoal, which is applied in solid fuel, biofuel, waste fuel, etc., can solve the problems of air pollution, resource waste, etc., and achieve the effects of high carbon content, avoiding waste, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

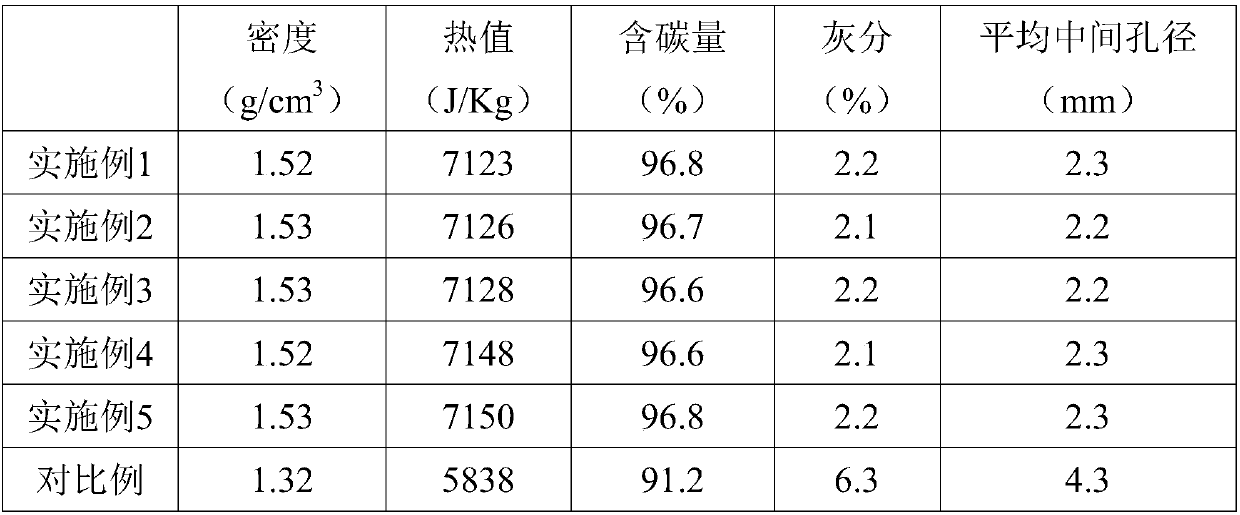

Examples

Embodiment 1

[0026] A kind of method utilizing enoki mushroom slag to prepare mechanism charcoal, comprises the following steps:

[0027] (1) Dissolve the remaining bacterium slag after the cultivation Flammulina velutipes matures in the hydrochloric acid solution of 10% mass concentration and carry out ultrasonic agitation at 45 ℃, clean with deionized water after the ultrasonic agitation treatment until the solution becomes neutral, then dissolve in 9% Ultrasonic stirring is carried out in the sodium bicarbonate solution of high concentration, and after stirring, it is washed with deionized water until the solution becomes neutral. The frequency of the two ultrasonic waves is 40KHz, and the stirring speed is 100r / min;

[0028] (2) Flammulina velutipes slag after hydrochloric acid solution and sodium bicarbonate solution treatment and protease, amylase, cellulase are mixed and reacted at 33 ℃;

[0029] (3) Send the above-mentioned reacted product into a carbonization furnace for carboniza...

Embodiment 2

[0031] A kind of method utilizing enoki mushroom slag to prepare mechanism charcoal, comprises the following steps:

[0032] (1) Dissolve the remaining bacterium slag after the cultivation Flammulina velutipes matures in the sulfuric acid solution of 16% mass concentration and carry out ultrasonic agitation at 55 ℃, clean with deionized water after the ultrasonic agitation treatment until the solution becomes neutral, then dissolve in 8% Ultrasonic stirring is carried out in the sodium bicarbonate solution of high concentration, and after stirring, it is washed with deionized water until the solution becomes neutral. The frequency of the two ultrasonic waves is 40KHz, and the stirring speed is 100r / min;

[0033] (2) Flammulina velutipes slag after sulfuric acid solution, sodium bicarbonate solution treatment and serine protease, gamma-amylase, cellulase are mixed and reacted at 32 ℃;

[0034] (3) Send the above-mentioned reacted product into a carbonization furnace for carboni...

Embodiment 3

[0037] A kind of method utilizing enoki mushroom slag to prepare mechanism charcoal, comprises the following steps:

[0038] (1) Dissolve the remaining bacterium slag after the cultivation Flammulina velutipes matures in the nitric acid solution of 14% mass concentration and carry out ultrasonic agitation at 45 ℃, clean with deionized water after the ultrasonic agitation treatment until the solution becomes neutral, then dissolve in 10% Ultrasonic stirring is carried out in the sodium bicarbonate solution of high concentration, and after stirring, it is washed with deionized water until the solution becomes neutral. The frequency of the two ultrasonic waves is 40KHz, and the stirring speed is 100r / min;

[0039] (2) Flammulina velutipes slag after nitric acid solution, sodium bicarbonate solution treatment and cysteine protease, aspartic acid protease, gamma-amylase, cellulase are mixed and reacted at 34 ℃;

[0040] (3) Send the above-mentioned reacted product into a carboniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com