Antibacterial film-forming high-molecule liquid and preparation method thereof

A polymer, film-forming technology, applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, inorganic active ingredients, etc. To achieve the effect of improving the action efficiency, improving the bacteriostatic effect, and enhancing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

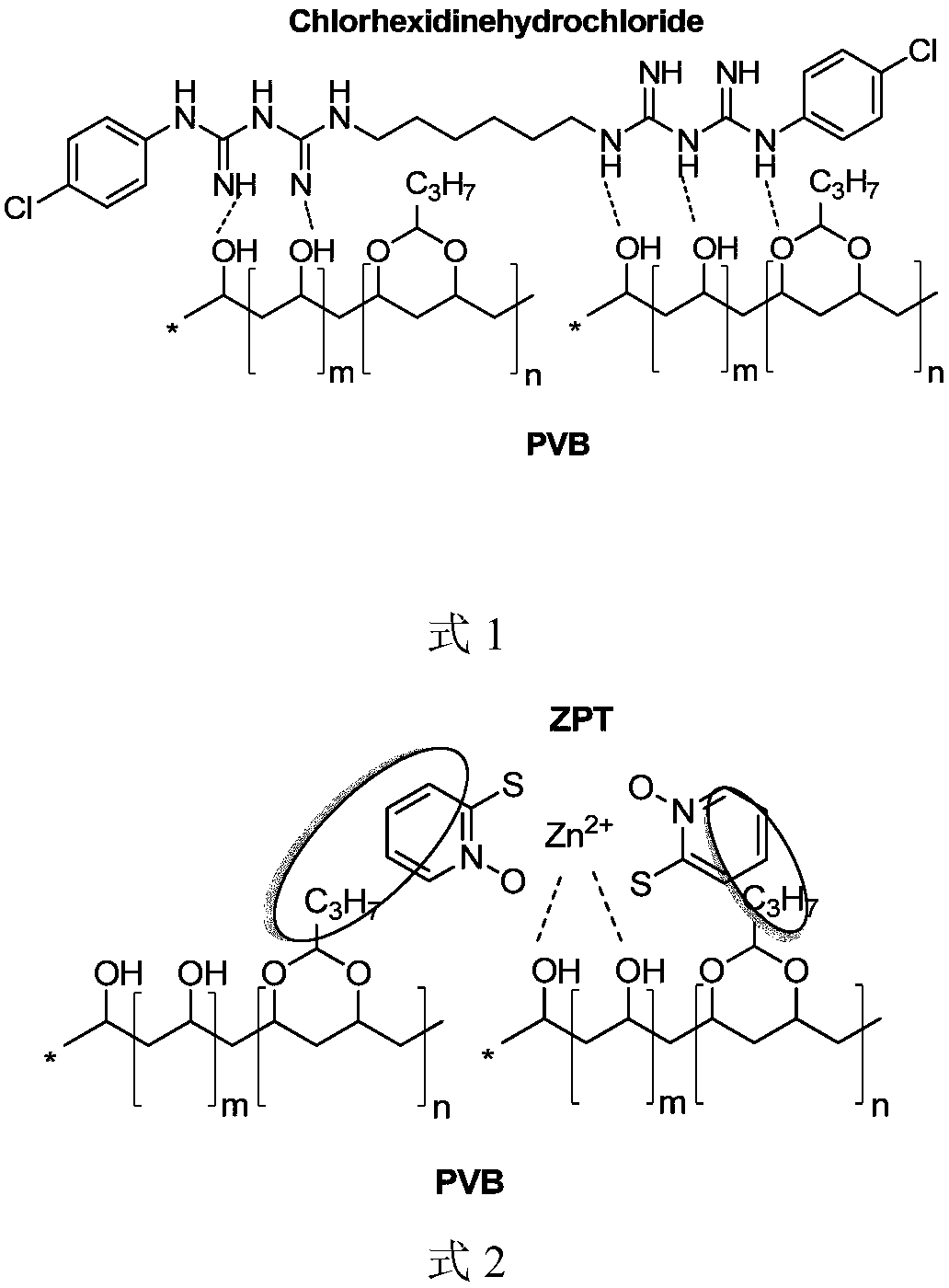

Method used

Image

Examples

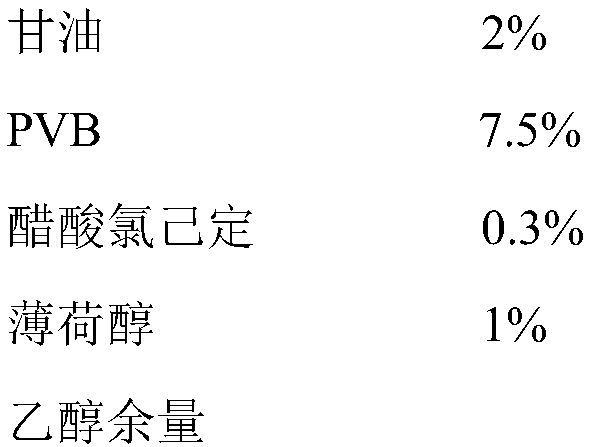

Embodiment 1

[0022] composition:

[0023]

[0024] Preparation:

[0025] Dissolve PVB in ethanol, then add chlorhexidine acetate and stir well to obtain a mixed solution. An appropriate amount of glycerin and menthol are added to the mixed solution to obtain a bacteriostatic polymer solution.

Embodiment 2~6

[0027] The preparation method is the same as Example 1, except that polymethacrylic acid (Example 2), chitosan (Example 3), polyacrylamide (Example 4), Carbomer (Example 5) are used respectively. ), PVP (embodiment 6) as polymer film-forming material.

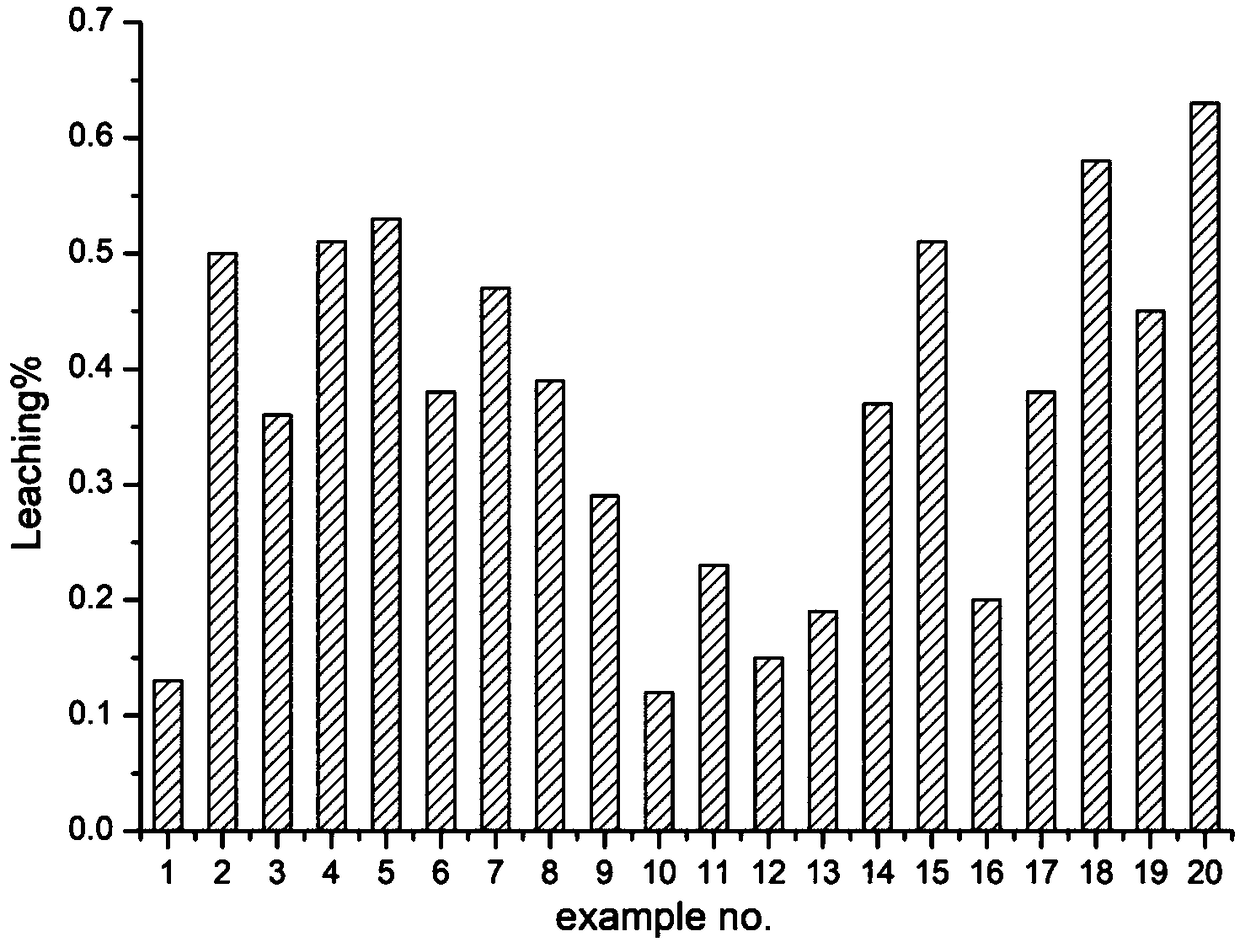

Embodiment 7~18

[0029] Preparation method is identical with embodiment 1, difference is, respectively adopt miconazole nitrate (embodiment 7), terbinafine hydrochloride (embodiment 8), ketoconazole (embodiment 9), ZPT (embodiment 10 ), amorolfine hydrochloride (embodiment 11), ZPT+chlorhexidine acetate (embodiment 12), benzalkonium chloride (embodiment 13), ciclopirox olamine (embodiment 14), sodium salicylate (implementation Example 15), Amorolfine Hydrochloride+ZPT (Example 16), Amorolfine Hydrochloride+ZPT+Potassium Sorbate (Example 17), Kathone (Example 18).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com