Composite anode material of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve problems such as volume expansion, active material shedding, and poor conductivity of nano-silicon, and achieve improved Conductivity, low cost, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

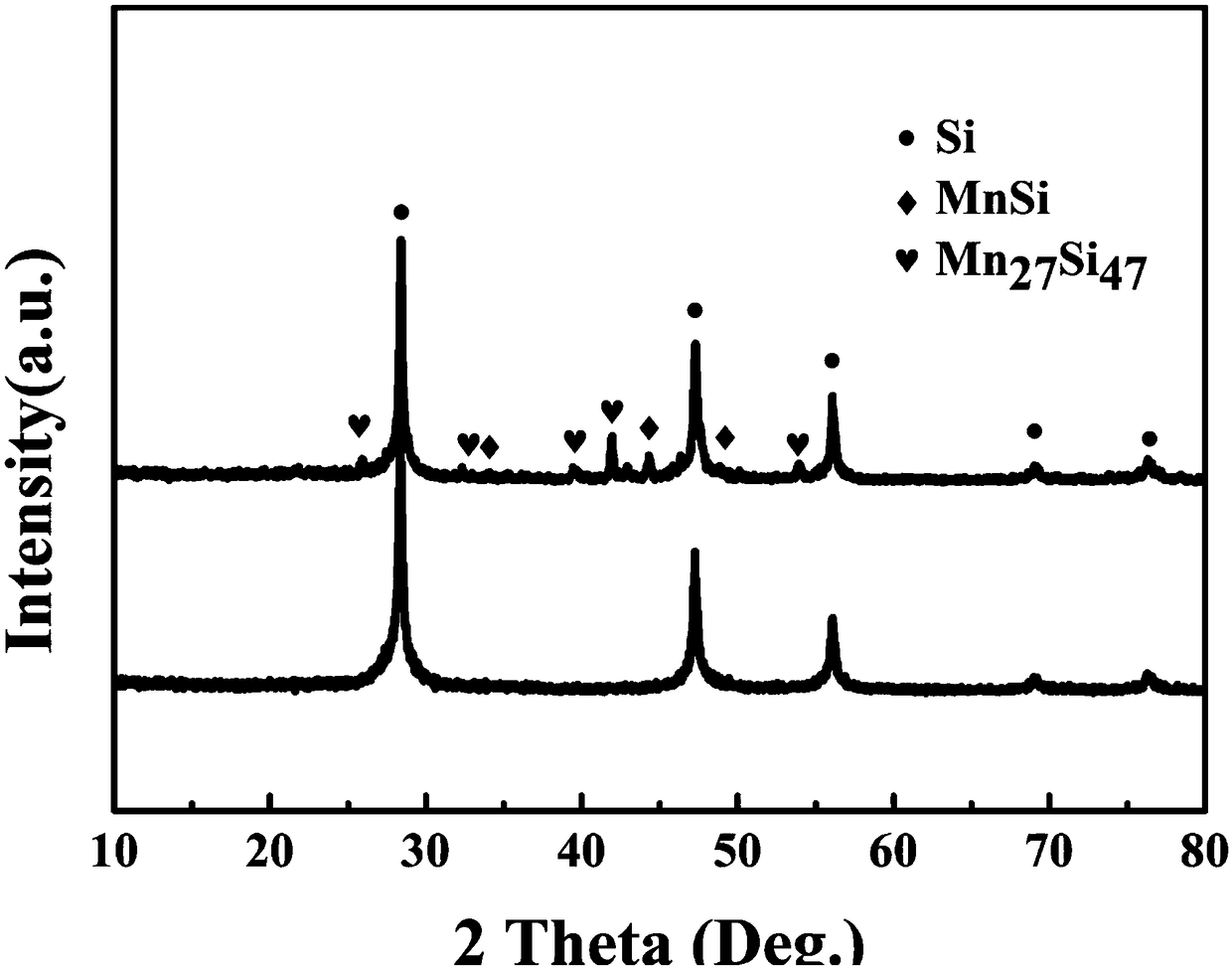

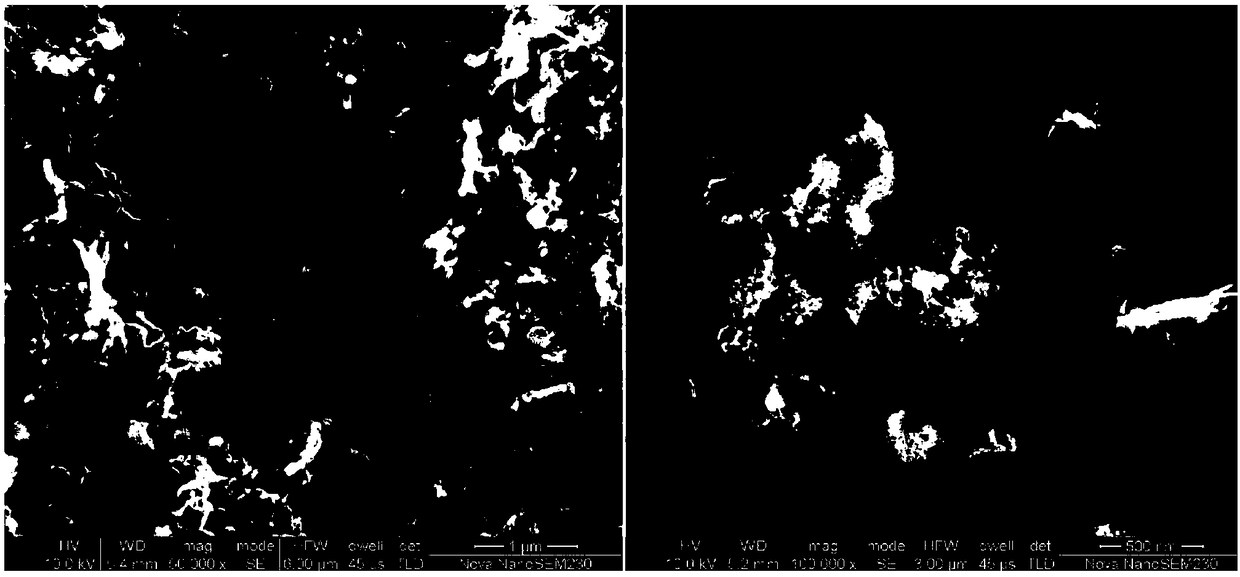

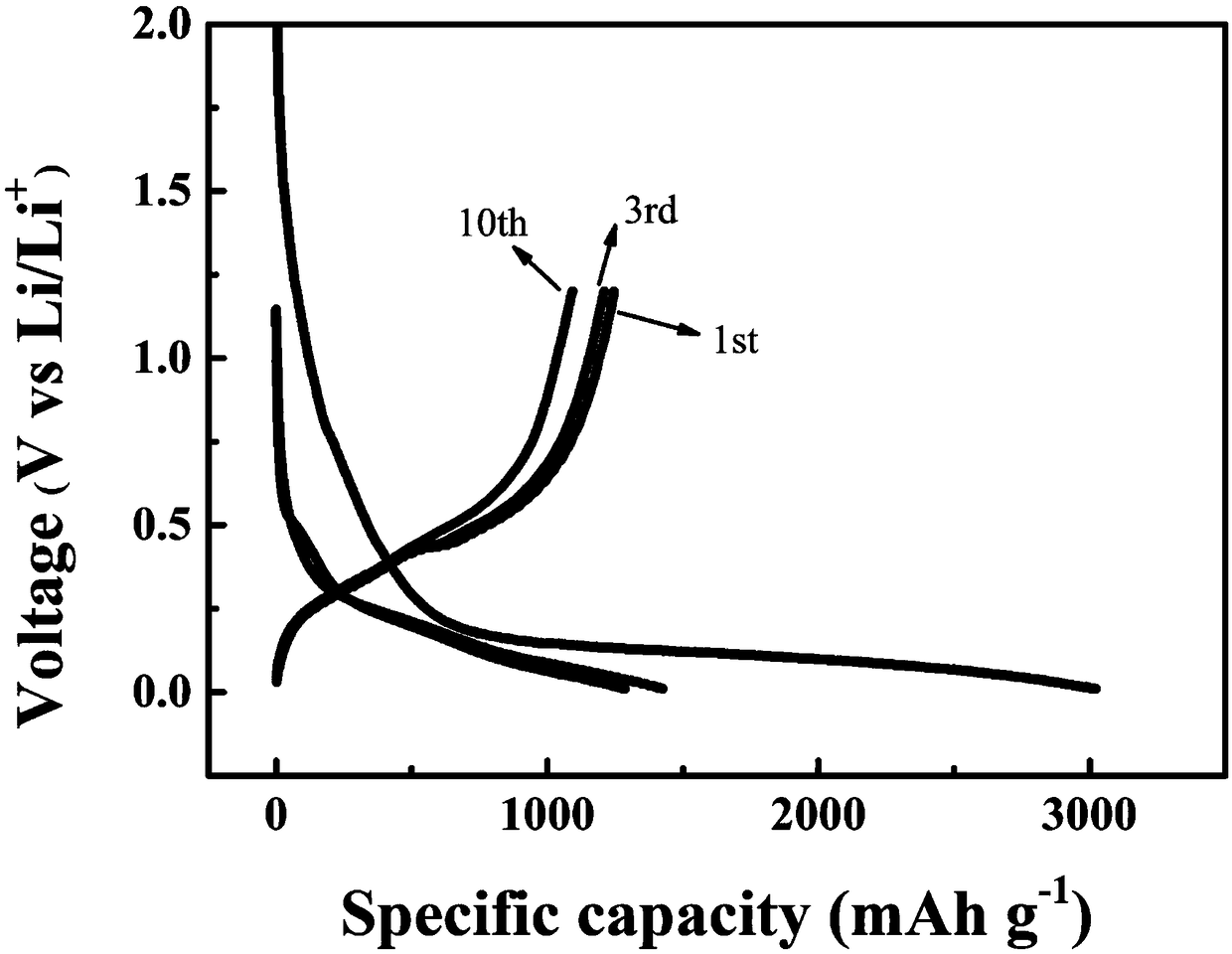

Embodiment 1

[0036] Dissolve 0.45g of cetyltrimethylammonium bromide particles in 100mL of hydrochloric acid solution with a concentration of 1mol / L at 3°C, then add 0.5g of manganese acetate and disperse with ultrasonic stirring for 20min at an ultrasonic frequency of 80Hz. Then add 0.2g of nano silicon dioxide, after stirring evenly, continue to ultrasonically disperse for 30min, the ultrasonic frequency is 100Hz, keep the temperature constant during the process, then add 0.8g of ammonium peroxodisulfate, and stir vigorously, and add dropwise after white emulsion appears 1 mL of pyrrole was reacted for 8 h and the resulting solution was lyophilized. Control the mass ratio of the obtained intermediate product to sodium chloride at 1:13, add magnesium powder and sodium chloride, grind, and obtain the precursor after 20 minutes. The precursor was burned in two stages in an inert atmosphere, reacted at 118°C for 2 hours, the heating rate was 2°C / min, and then reacted at 650°C for 5 hours, th...

Embodiment 2

[0039] Dissolve 0.35g of cetyltrimethylammonium bromide particles in 120mL hydrochloric acid solution with a concentration of 3mol / L at 2.5°C, then add 0.8g of manganese acetate and disperse with ultrasonic stirring for 20min at a frequency of 40Hz. Then add 2.0g of nano silicon dioxide, after stirring evenly, continue to ultrasonically disperse for 45min, the ultrasonic frequency is 120Hz, keep the temperature constant during the process, then add 1.0g of ammonium peroxodisulfate, stir vigorously, and add dropwise after white emulsion appears 0.5 mL of pyrrole was reacted for 16 h and the resulting solution was lyophilized. Control the mass ratio of the obtained intermediate product to sodium chloride at 1:10, add magnesium powder and sodium chloride, grind, and obtain the precursor after 20 minutes. The precursor was fired in two stages in an inert atmosphere, reacted at 158°C for 2 hours, the heating rate was 1°C / min, and then reacted at 700°C for 5 hours, the heating rate ...

Embodiment 3

[0042] Dissolve 0.55g of cetyltrimethylammonium bromide particles in 200mL of hydrochloric acid solution with a concentration of 1.5mol / L at 5°C, then add 0.5g of manganese acetate and disperse with ultrasonic stirring for 60min at an ultrasonic frequency of 20Hz. Then add 1.5g of nano-silica, stir evenly, continue to ultrasonically disperse for 45min, the ultrasonic frequency is 120Hz, keep the temperature constant during the process, then add 1.0g of ammonium peroxodisulfate, stir vigorously, and add dropwise after white emulsion appears 0.2 mL of pyrrole was reacted for 24 h and the resulting solution was lyophilized. Control the mass ratio of the obtained intermediate product to sodium chloride at 1:10, add magnesium powder and sodium chloride, grind, and obtain the precursor after 20 minutes. The precursor was fired in two stages in an inert atmosphere, reacted at 300°C for 4 hours, the heating rate was 3°C / min, and then reacted at 650°C for 5 hours, the heating rate was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com