Preparation method of bismuth titanate nanosheet

A technology of nanosheets and bismuth titanate, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as troublesome product handling, and achieve the optimization of preparation process conditions, easy large-scale production, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Measure and weigh 6mmol tetrabutyl titanate and dissolve it in 60mL of absolute ethanol solvent to form a tetrabutyl titanate absolute ethanol solution with a concentration of 0.1mol / L, then drop in deionized water to hydrolyze to obtain the hydroxyl group of titanium Oxide precipitation, wash with absolute ethanol and deionized water;

[0042] 2) Disperse the precipitated titanium oxyhydroxide prepared in step 1) in a small amount of deionized water, add KOH tablet, and after stirring fully, adjust the volume to 40ml with deionized water to form a potassium hydroxide concentration of 8mol / L, Ti 4+ A suspension with an ion concentration of 0.15mol / L;

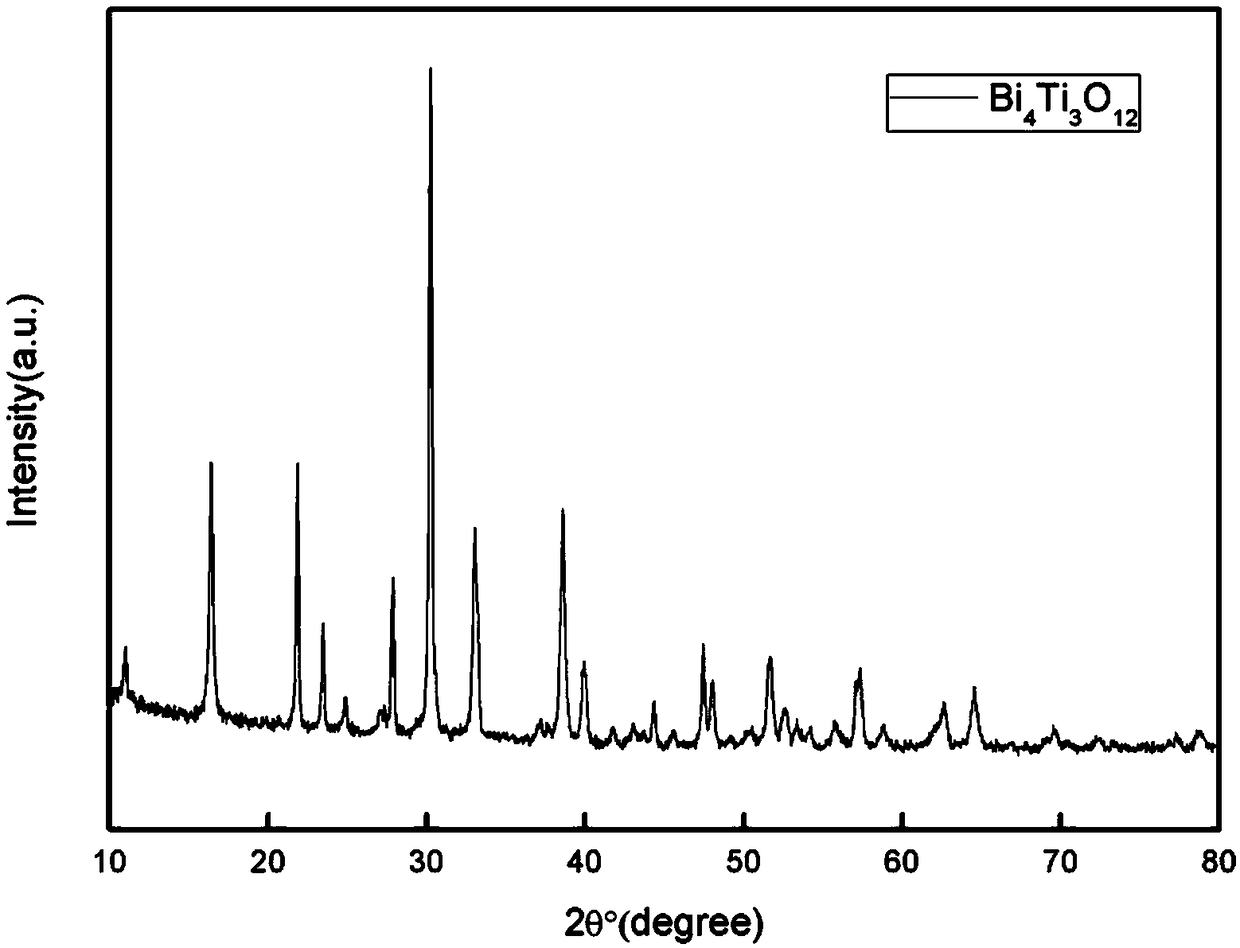

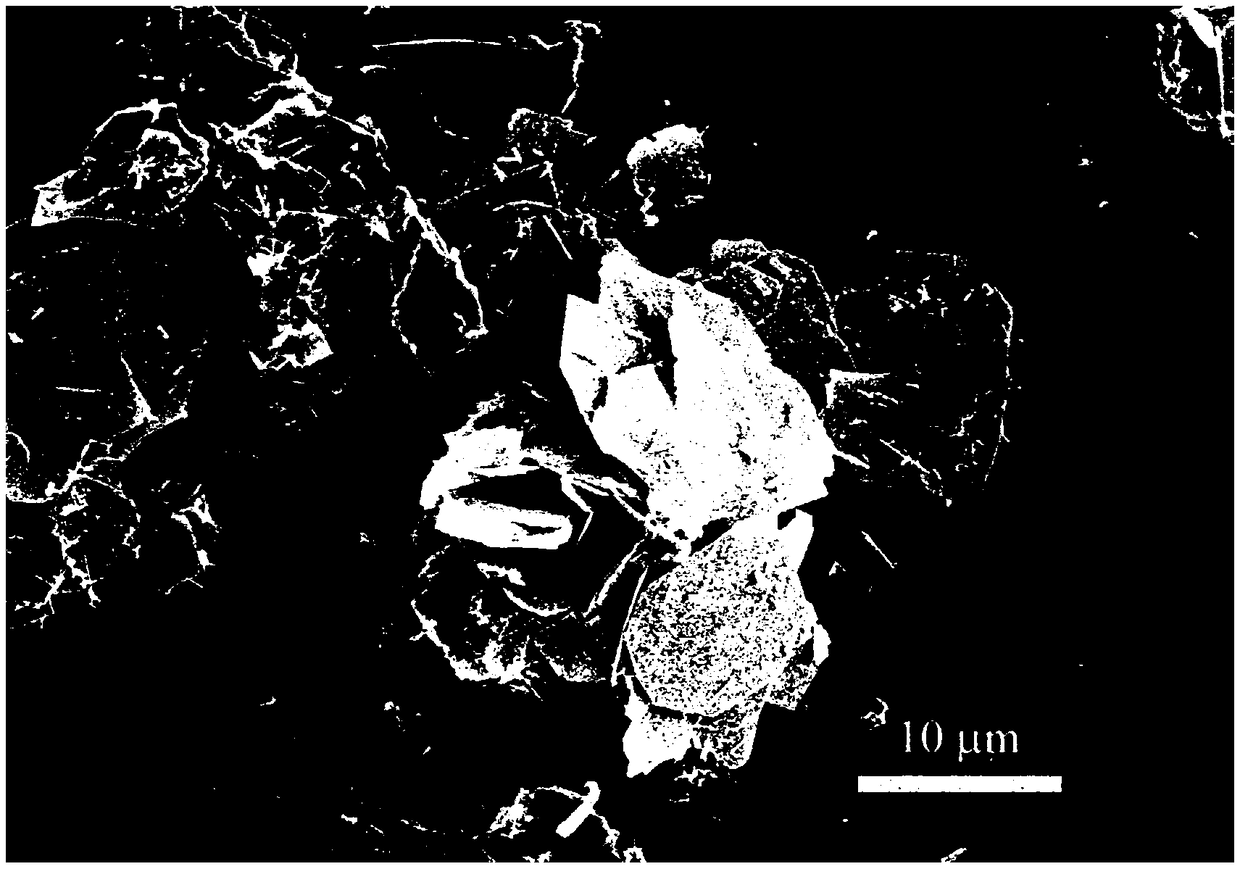

[0043] 3) Transfer the suspension prepared in step 2) to a hydrothermal reaction kettle, place it in a hydrothermal reaction at 200°C for 16 hours, and then obtain fresh potassium titanate nanowire powder through subsequent treatment. The SEM of potassium titanate nanowires photos such as figure 1 shown;

[0044] 4...

Embodiment 2

[0049] 1) Measure and weigh 9 mmol tetrabutyl titanate and dissolve it in 60 mL of absolute ethanol solvent to form a tetrabutyl titanate absolute ethanol solution with a concentration of 0.15 mol / L, then drop in deionized water to hydrolyze to obtain the hydroxyl group of titanium Oxide precipitation, wash with absolute ethanol and deionized water;

[0050] 2) Disperse the precipitated titanium oxyhydroxide prepared in step 1) in a small amount of deionized water, add KOH tablet, and after stirring fully, adjust the volume to 40ml with deionized water to form a potassium hydroxide concentration of 10mol / L, Ti 4+ A suspension with an ion concentration of 0.225mol / L;

[0051] 3) Transfer the suspension prepared in step 2) to a hydrothermal reaction kettle, place it in a hydrothermal reaction at 200°C for 24 hours, and then obtain fresh potassium titanate nanowire powder through subsequent treatment;

[0052] 4) Disperse the potassium titanate nanowires obtained in step 3) in ...

Embodiment 3

[0057] 1) Measure and weigh 9 mmol tetrabutyl titanate and dissolve it in 60 mL of absolute ethanol solvent to form a tetrabutyl titanate absolute ethanol solution with a concentration of 0.15 mol / L, then drop in deionized water to hydrolyze to obtain the hydroxyl group of titanium Oxide precipitation, wash with absolute ethanol and deionized water;

[0058] 2) Disperse the precipitated titanium oxyhydroxide prepared in step 1) in a small amount of deionized water, add KOH tablet, and after stirring fully, adjust the volume to 40ml with deionized water to form a potassium hydroxide concentration of 10mol / L, Ti 4+ A suspension with an ion concentration of 0.225mol / L;

[0059] 3) Transfer the suspension prepared in step 2) to a hydrothermal reaction kettle, place it in a hydrothermal reaction at 200°C for 20 hours, and then obtain fresh potassium titanate nanowire powder through subsequent treatment;

[0060] 4) Disperse the potassium titanate nanowires obtained in step 3) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com