Antibacterial organic silicon rubber material and preparation method thereof

An organic silica gel and silica gel technology, which is applied in the field of antibacterial organic silica gel materials and its preparation, can solve the problems of insignificant heat dissipation and heat conduction effect, low requirements for equipment and reaction conditions, and poor antibacterial properties, and meets the requirements of equipment and reaction conditions. High, low price, obvious antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

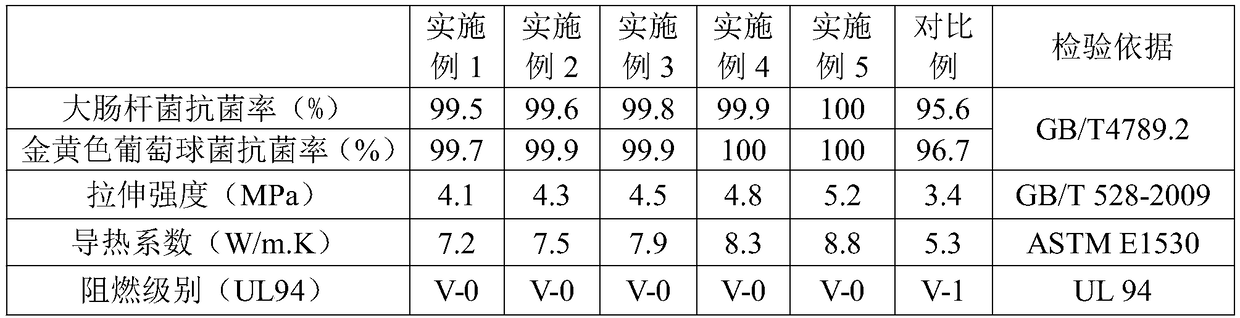

Examples

Embodiment 1

[0027] A preparation method of an antibacterial organic silica gel material, comprising the steps of:

[0028] 1) Dissolve 10 g of thiadioic acid and 15.5 g of bis(4-aminophenoxy)dimethylsilane in 80 g of dimethyl sulfoxide to form a solution, and then add 1.5 g of dicyclohexylcarbodiimide, 1 -Hydroxybenzotriazole 1g, and place in the autoclave that is equipped with thermometer, pressure gauge, nitrogen inlet, pressure release port, and nitrogen replaces the air in the container. The temperature was raised to 200° C. over 1.5 hours, and kept at a pressure of 2 MPaG for 2 hours. Then, it takes 1 hour to raise the temperature to 270°C, and at the same time, the pressure is reduced to normal pressure during the heating period, and it is kept for 30 minutes, then cooled, then precipitated in water, washed 3 times with ethanol, and then placed in a vacuum oven at 90°C Bake for 18 hours to obtain an intermediate product;

[0029] 2) Dissolve 30 g of double-terminated hydroxy silic...

Embodiment 2

[0035] A preparation method of an antibacterial organic silica gel material, comprising the steps of:

[0036] 1) Dissolve 10g of thiadioic acid and 15.5g of bis(4-aminophenoxy)dimethylsilane in 90g of N,N-dimethylformamide to form a solution, and then add dicyclohexylcarbodiethylene 1.8 g of amine and 1 g of 1-hydroxybenzotriazole were placed in an autoclave equipped with a thermometer, a pressure gauge, a helium inlet, and a pressure release port, and the air in the container was replaced with helium. The temperature was raised to 210° C. over 1.7 hours, and kept at a pressure of 2.2 MPaG for 2 hours. Then, use 1.2 hours to raise the temperature to 275°C, and at the same time, reduce the pressure to normal pressure during the heating period, keep it for 30 minutes, then cool it, then settle it in water, wash it with ethanol 4 times, and then put it in a vacuum oven at 93°C Bake for 20 hours to obtain an intermediate product;

[0037] 2) Dissolve 33g of double-terminated hy...

Embodiment 3

[0043] A preparation method of an antibacterial organic silica gel material, comprising the steps of:

[0044] 1) Dissolve 10 g of thiadioic acid and 15.5 g of bis(4-aminophenoxy)dimethylsilane in 100 g of N-methylpyrrolidone to form a solution, and then add 2 g of dicyclohexylcarbodiimide, 1 -Hydroxybenzotriazole 1g is placed in an autoclave equipped with a thermometer, a pressure gauge, a neon gas inlet, and a pressure release port, and the neon gas replaces the air in the container. The temperature was raised to 220° C. over 2 hours, and kept at a pressure of 2.2 MPaG for 2 hours. Then, it takes 1.3 hours to raise the temperature to 280°C, and at the same time, the pressure is reduced to normal pressure during the heating period, and it is kept for 30 minutes, then cooled, then precipitated in water, washed 5 times with ethanol, and then placed in a vacuum drying oven at 96°C Bake for 21 hours to obtain an intermediate product;

[0045] 2) Dissolve 35g of double-terminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com