Novel adhesive for adhesive sticker

An adhesive, a new type of technology, applied in the field of self-adhesive, can solve the problems of small application range, poor waterproof performance, poor high temperature resistance, etc., and achieve the effect of wide application range, good waterproof performance and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

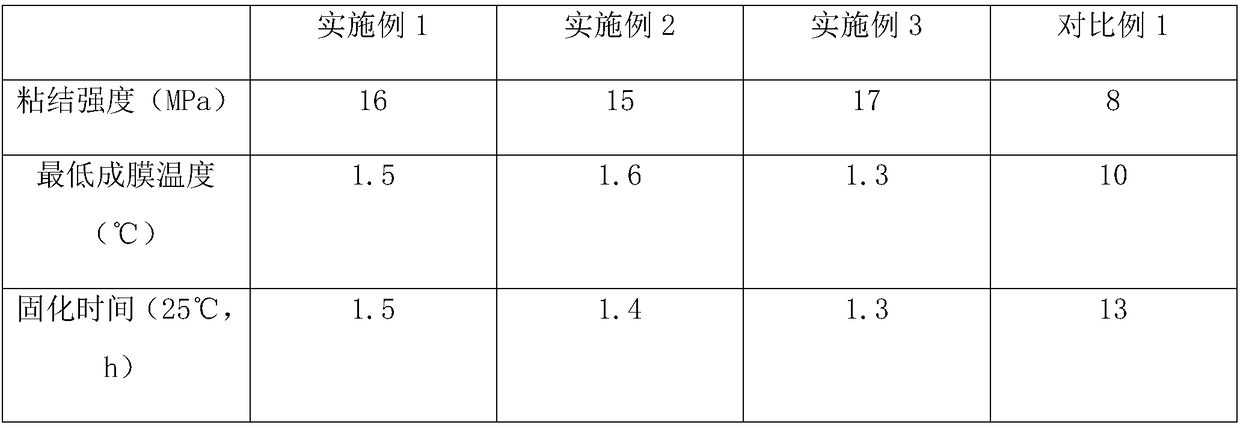

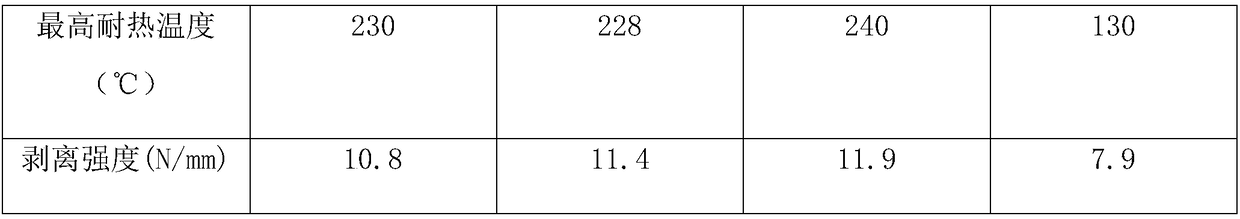

Examples

Embodiment 1

[0016] A new type of adhesive for self-adhesive, which is composed of the following raw materials in parts by weight: 6 parts of isomeric tridecanol polyoxyethylene ether, 30 parts of dibutyl phthalate, 40 parts of 15% polyvinyl formal, oxidized 20 parts of copper, 18 parts of aluminum hydroxide, 8 parts of sodium hexametaphosphate, 20 parts of modified epoxy resin, 10 parts of hydroxyethyl acacia gum, 8 parts of hydroxypropyl cellulose, and 30 parts of emulsifier OP-10.

[0017] Wherein, the preparation method of described modified epoxy resin is: (1) add 180mL deionized water in the four-necked bottle, then add 0.5mol alkylbenzene sulfonate sodium and 0.2mol potassium persulfate and feed nitrogen into the four-necked bottle Air in the bottle, then stirred for 50min to obtain solution A; (2) add 0.6mol epoxy resin and 0.2mol vinyl acetate to solution A in step (1), stir for 2h, then heat up to 80°C, react After 50 minutes, the temperature was lowered to 50°C to obtain a modif...

Embodiment 2

[0019] A new type of adhesive for self-adhesive, which is composed of the following raw materials in parts by weight: 12 parts of isomeric tridecanol polyoxyethylene ether, 40 parts of dibutyl phthalate, 50 parts of 15% polyvinyl formal, oxidized 24 parts of copper, 22 parts of aluminum hydroxide, 14 parts of sodium hexametaphosphate, 30 parts of modified epoxy resin, 12 parts of hydroxyethyl acacia gum, 12 parts of hydroxypropyl cellulose, 38 parts of emulsifier OP-10.

[0020] Wherein, the preparation method of described modified epoxy resin is: (1) add 180mL deionized water in the four-necked bottle, then add 0.5mol alkylbenzene sulfonate sodium and 0.2mol potassium persulfate and feed nitrogen into the four-necked bottle Air in the bottle, then stirred for 50min to obtain solution A; (2) add 0.6mol epoxy resin and 0.2mol vinyl acetate to solution A in step (1), stir for 2h, then heat up to 80°C, react After 50 minutes, the temperature was lowered to 50°C to obtain a modifi...

Embodiment 3

[0022] A new type of adhesive for self-adhesive, which is composed of the following raw materials in parts by weight: 9 parts of isomeric tridecanol polyoxyethylene ether, 35 parts of dibutyl phthalate, 45 parts of 15% polyvinyl formal, oxidized 22 parts of copper, 20 parts of aluminum hydroxide, 11 parts of sodium hexametaphosphate, 25 parts of modified epoxy resin, 11 parts of hydroxyethyl acacia gum, 10 parts of hydroxypropyl cellulose, 34 parts of emulsifier OP-10.

[0023] Wherein, the preparation method of described modified epoxy resin is: (1) add 180mL deionized water in the four-necked bottle, then add 0.5mol alkylbenzene sulfonate sodium and 0.2mol potassium persulfate and feed nitrogen into the four-necked bottle Air in the bottle, then stirred for 50min to obtain solution A; (2) add 0.6mol epoxy resin and 0.2mol vinyl acetate to solution A in step (1), stir for 2h, then heat up to 80°C, react After 50 minutes, the temperature was lowered to 50°C to obtain a modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com