Composite microbial inoculant for degrading shale gas-water based drilling cutting pollutants as well as preparation method and use method of composite microbial inoculant

A compound inoculant and microorganism technology, applied in the directions of microorganism-based methods, biochemical equipment and methods, and the restoration of polluted soil, can solve the problems of land occupation, surrounding soil and water pollution, and environmental risks, etc. The effect of harmless treatment, beneficial to resource utilization, and reducing the risk of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

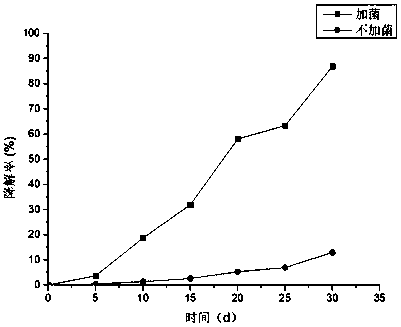

Embodiment 1

[0021] Pseudomonas aeruginosa, Acinetobacter, Bacillus subtilis, and Micrococcaceae were respectively cultured on a test tube slant, activated by inoculating shake flasks, and cultured in seed tanks for the first generation, respectively. The first-generation bacterial suspension cultured in the seed tank was inserted into the fermenter liquid culture according to the inoculation amount of 5% of the fermenter medium volume. Yeast extract of 1.5% of water quality, sodium chloride of 0.1% of water quality, dipotassium hydrogen phosphate of 0.5% of water quality, in the first-generation bacterial suspension, Pseudomonas aeruginosa, Acinetobacter, Bacillus subtilis, Micrococci were inoculated at a mass ratio of 1:0.5:1:1, the culture temperature was 25°C, and the culture time was 24 hours. Microscopic examination, when the number of viable bacteria in the composite bacterial agent reached 10 8 cfu / ml, a liquid microbial composite bacterial agent for degrading shale gas water-based...

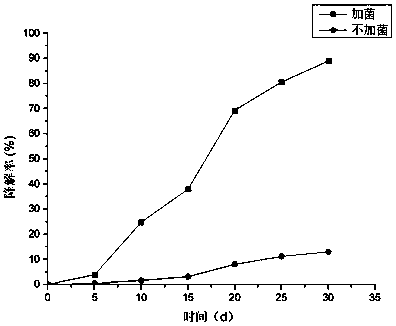

Embodiment 2

[0024] Pseudomonas aeruginosa, Acinetobacter, Bacillus subtilis, and Micrococcaceae were respectively cultured on a test tube slant, activated by inoculating shake flasks, and cultured in seed tanks for the first generation, respectively. The first-generation bacterial suspension cultured in the seed tank is inserted into the fermenter liquid culture according to the inoculum volume of 10% of the fermenter medium volume. Yeast paste with 2% water quality, sodium chloride with 0.15% water quality, and dipotassium hydrogen phosphate with 0.7% water quality are composed. Micrococci were inoculated at a mass ratio of 2:1:2:2, the culture temperature was 35°C, and the culture time was 72 hours. Microscopic examination showed that when the number of viable bacteria in the compound bacterial agent reached 10 12 cfu / ml, a liquid microbial composite bacterial agent for degrading shale gas water-based drilling cuttings pollutants was prepared.

[0025] Take 5 kg of shale gas water-base...

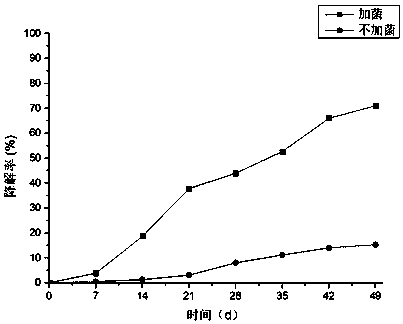

Embodiment 3

[0027] Pseudomonas aeruginosa, Acinetobacter, Bacillus subtilis, and Micrococcaceae were respectively cultured on a test tube slant, activated by inoculating shake flasks, and cultured in seed tanks for the first generation, respectively. The first-generation bacterial suspension cultured in the seed tank is inserted into the fermenter liquid culture according to the inoculum volume of 10% of the fermenter medium volume. Yeast paste with 2% water quality, sodium chloride with 0.15% water quality, and dipotassium hydrogen phosphate with 0.7% water quality are composed. Micrococci were inoculated at a mass ratio of 2:1:2:2, the culture temperature was 35°C, and the culture time was 72 hours. Microscopic examination showed that the number of viable bacteria in the composite bacterial agent reached 10 12cfu / ml. Add 30% of the mass of the fermented liquid microbial composite bacterial agent to the bran after high temperature sterilization (it can also be any one or several of cind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com