Electrostatic spinning based pure-phase erbium titanate nanomaterial preparation method and application

An electrospinning method and nano-material technology, which is applied in the field of preparation of pure phase erbium titanate Er2Ti2O7 nano-materials by electrospinning method, to simplify the double-doping or multi-doping process, the preparation method is simple and easy, and the doping process is avoided Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Mix acetic acid and DMF at a volume ratio of 0.2:1, and form a transparent solution by magnetic stirring; then add erbium nitrate and dissolve it fully by stirring, the quality of acetic acid and DMF is 5 times that of erbium nitrate; add it under rapid stirring For tetrabutyl titanate, the mass of acetic acid and DMF is 6 times that of tetrabutyl titanate; finally add PVP with a mass fraction of 5%, and obtain an electrospinning precursor solution after magnetic stirring. Under the conditions of control voltage of 10KV and flow rate of 15μl / m, a large amount of nanomaterials appeared on the collector. After the electrospinning was completed, the nanomaterials on the collector were transferred to the muffle furnace and heated at 8°C / min. The rate is increased to 800 ° C for 1 hour, and the pure phase Er with high crystallization performance can be obtained. 2 Ti 2 o 7 nanomaterials.

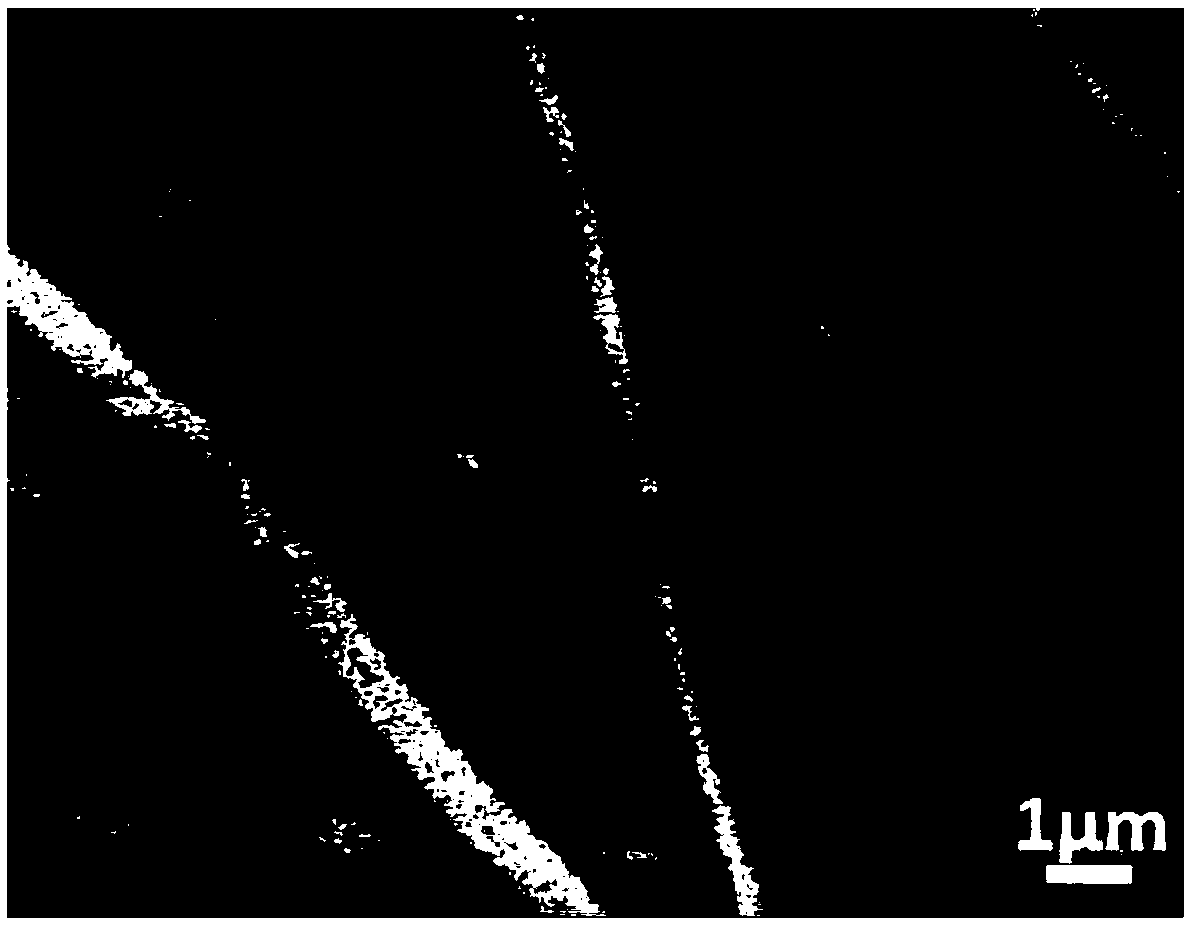

[0050] figure 1 gives the obtained Er 2 Ti 2 o 7 Scanning electron micrograph (...

Embodiment 2

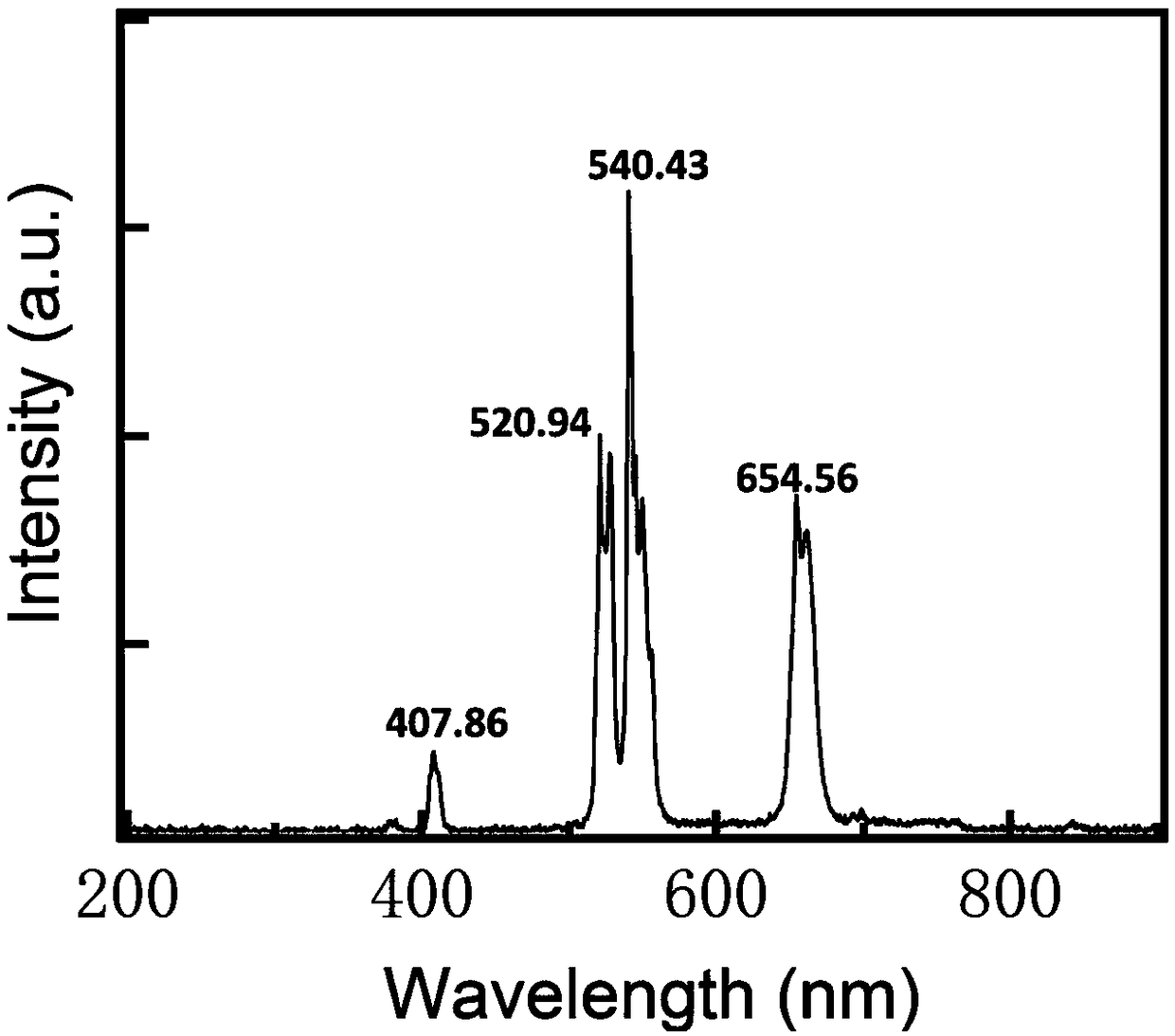

[0052] Mix acetic acid and DMF at a volume ratio of 0.4:1, and form a transparent solution by magnetic stirring; then add erbium nitrate and dissolve it fully by stirring, the quality of acetic acid and DMF is 8 times that of erbium nitrate; add it under rapid stirring For tetrabutyl titanate, the mass of acetic acid and DMF is 8 times that of tetrabutyl titanate; finally, PVP with a mass fraction of 7% is added, and the electrospinning precursor solution is obtained after magnetic stirring. Under the condition that the control voltage is 20KV and the flow rate is 10μl / m, a large amount of nanomaterials appear on the collector. After the electrospinning is completed, the nanomaterials on the collector are transferred to the muffle furnace and heated at 8°C / min. Raise the rate to 700°C for 2 hours to obtain a pure-phase Er2Ti2O7 nanomaterial with high crystallization performance, from figure 2 It can be seen that the positions of the obtained luminescence peaks are mainly two ...

Embodiment 3

[0055] Mix acetic acid and DMF at a volume ratio of 0.4:1, and form a transparent solution by magnetic stirring; then add erbium nitrate and dissolve it fully by stirring, the quality of acetic acid and DMF is 6 times that of erbium nitrate; add it under rapid stirring For tetrabutyl titanate, the mass of acetic acid and DMF is 8 times that of tetrabutyl titanate; finally add PVP with a mass fraction of 8%, and obtain an electrospinning precursor solution after magnetic stirring. Under the conditions of a control voltage of 15KV and a flow rate of 5 μl / m, a large amount of nanomaterials appeared on the collector. After the electrospinning was completed, the nanomaterials on the collector were transferred to the muffle furnace and heated at 9°C / min. If the temperature is increased to 600°C for 3 hours, a pure-phase Er2Ti2O7 nanomaterial with high crystallization performance can be obtained.

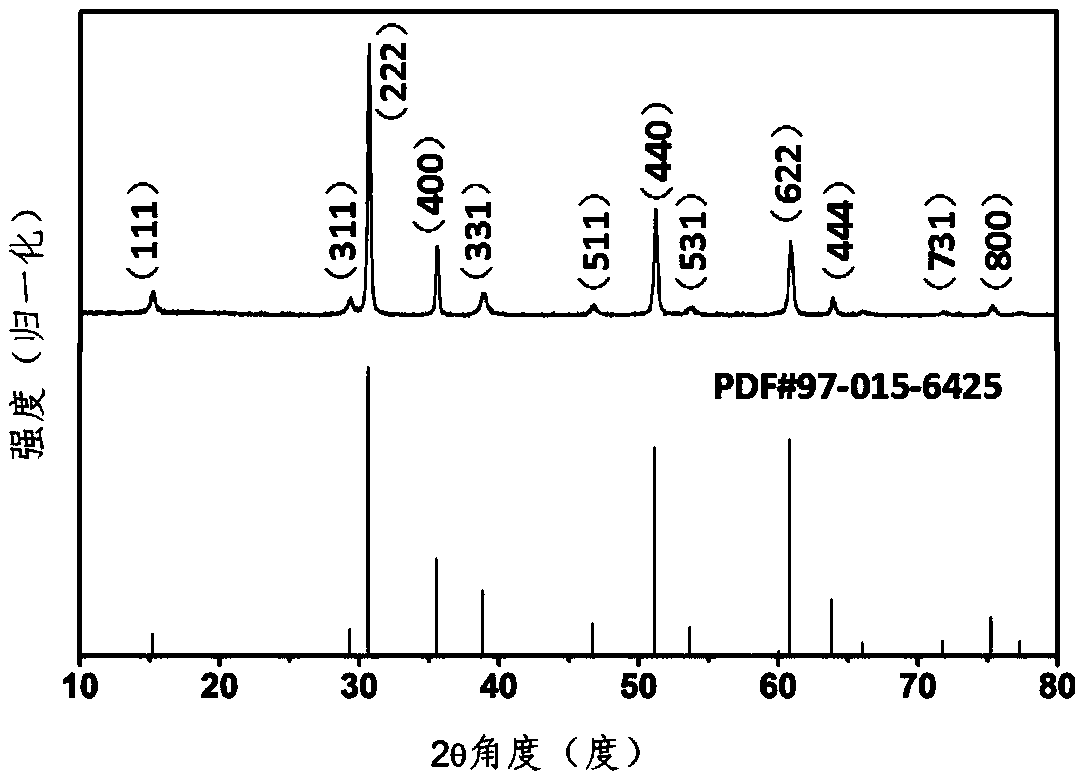

[0056] image 3 Given the X-ray diffraction pattern of the obtained nanomaterials, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com