Preparation method for carbon fuel of high-activity direct carbon fuel cell

A fuel cell and fuel preparation technology, applied in fuel cells, carbon preparation/purification, circuits, etc., can solve problems such as increasing contact area, unacceptable metal ions, and poor infiltration effect of pure carbon solid materials, etc., to achieve Easy to operate, simple steps, beneficial effect on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of bamboo carbon fuel preparation method of highly active direct carbon fuel cell, comprises the following steps:

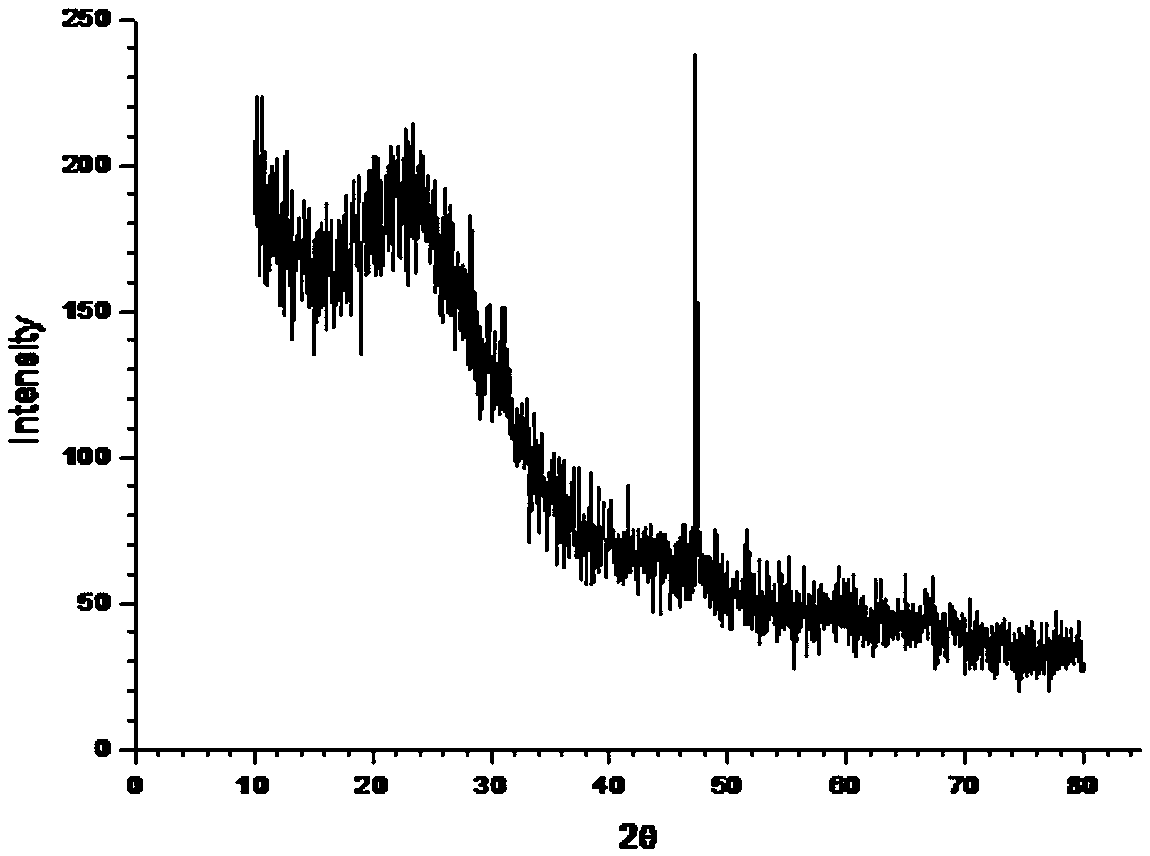

[0019] Bamboo fiber is used as a renewable biomass raw material and crushed. Add appropriate amount of mechanically crushed bamboo fiber into the open container, put the bamboo fiber together with the open container into the tube heating furnace, and pass it into the nitrogen removal furnace. The air in the cavity, and maintain a nitrogen atmosphere, first heat at 50-120°C for a period of time to dry the bamboo fiber, then quickly raise the temperature to about 400-800°C, heat for more than 8 hours, and finally slowly under the protection of nitrogen Cool to room temperature, promptly obtain described highly active bamboo carbon fuel. The resulting bamboo carbon fuel is characterized, and the test results are detailed in figure 1 and Table 1.

[0020] Table 1 Bamboo fiber carbon fuel X-ray photoelectron spectroscopy characterization results

[00...

Embodiment 2

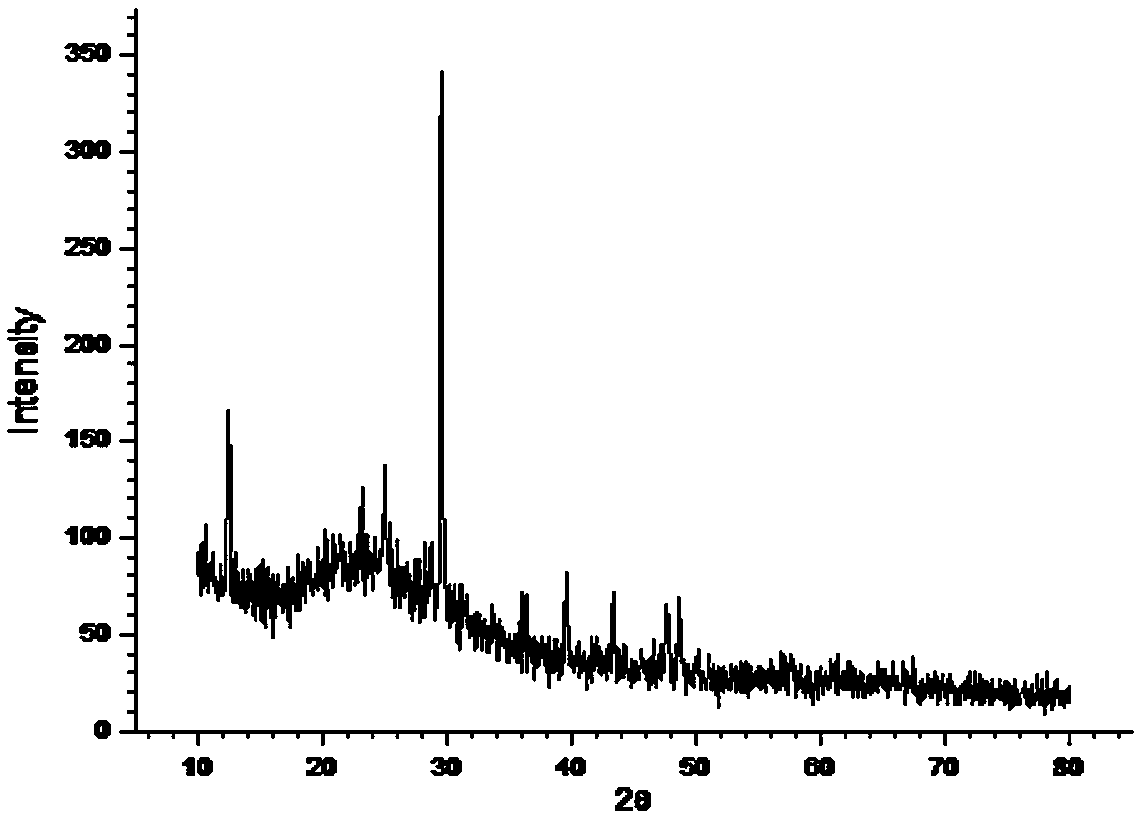

[0024] A method for preparing waste paper carbon fuel for a high-activity direct carbon fuel cell, comprising the following steps: taking waste paper boxes as solid waste and performing crushing treatment, adding an appropriate amount of mechanically crushed waste paper boxes into an open container, and Put the waste cartons together with the open container into the tubular heating furnace, pass nitrogen gas to remove the air in the furnace cavity, and keep the nitrogen atmosphere, first heat at 50-120°C for a period of time, dry the waste paper scraps, and then Rapidly raise the temperature to about 400-800°C, heat for more than 8 hours, and finally cool slowly to room temperature under the protection of nitrogen to obtain the highly active waste paper carbon fuel. Characterize the obtained waste paper carbon fuel, the test results are detailed in figure 2 and Table 2.

[0025] pass figure 2 It can be seen from Table 2 that the waste paper carbon fuel prepared by this met...

example

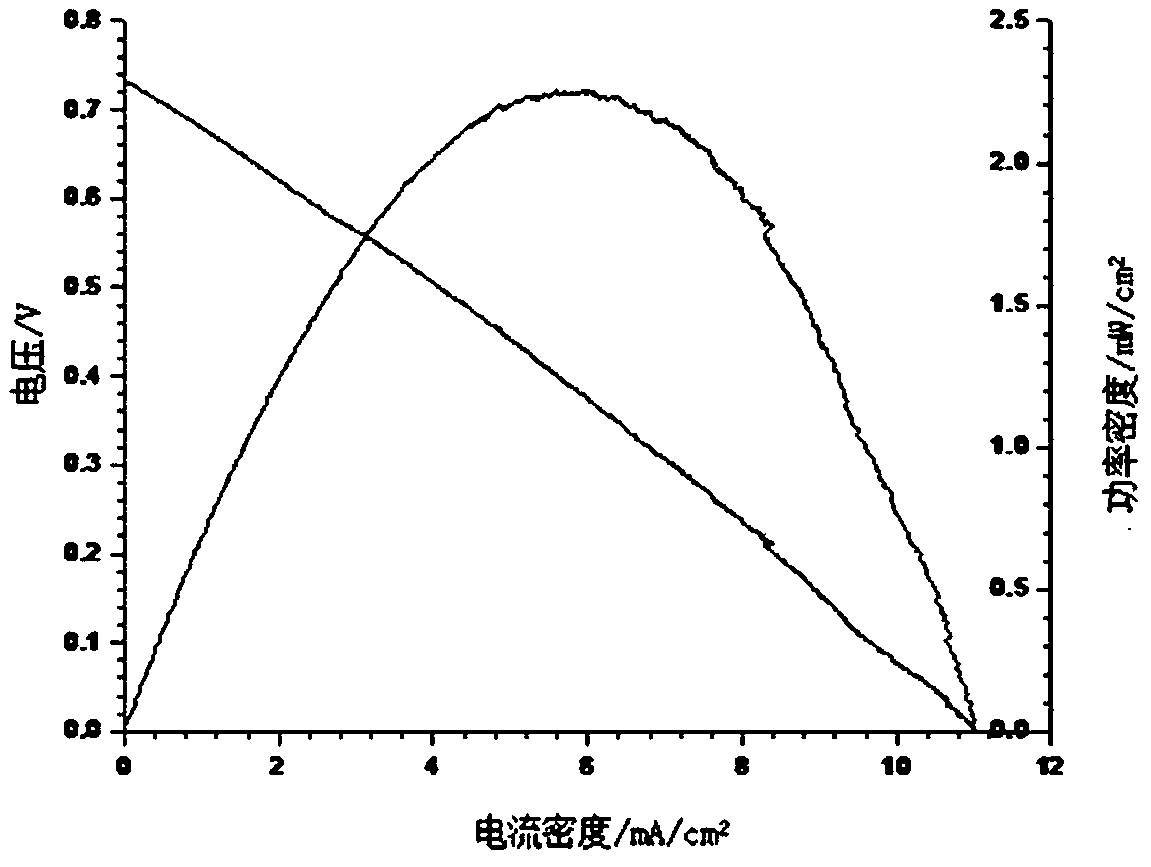

[0029] An example of the performance of a direct carbon fuel cell using bamboo carbon as fuel is listed below

[0030] Mix the above-mentioned bamboo carbon fuel and eutectic carbonate in a mass ratio of 1:1, put it into a straight carbon fuel cell device, and test the performance of the battery at 700 degrees Celsius. The obtained performance curve is shown in image 3 ;Depend on image 3 It can be seen that the straight carbon fuel cell made of bamboo carbon fuel has good battery performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com