Cationic phospholipid-polymer hybrid nanoparticle vaccine adjuvant co-loading antigen, mpla and imq, preparation method and application

A vaccine adjuvant and cation technology, which is applied in the field of cationic phospholipid-polymer hybrid nanoparticle vaccine adjuvant and preparation, can solve the problems of rapid drug leakage, low biocompatibility, and low drug load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of an antigen-loaded cationic phospholipid-polymer hybrid nanoparticle vaccine adjuvant, comprising the steps of:

[0035] S1: Dissolve the amphiphilic triblock copolymer PCL-b-PEG-b-PCL and the cationic phospholipid DOTAP in an organic solvent, then remove the organic solvent by rotary evaporation, and form a uniform film on the bottle wall, blow with nitrogen Dry the residual solvent, then put it in a vacuum drying oven, and dry it in vacuum for 12-24h; wherein, the molecular weight of the amphiphilic triblock copolymer PCL-b-PEG-b-PCL is 10000-24000, preferably 16000, wherein PEG The mass percentage of the hydrophilic segment is greater than 45%, the mass ratio of the amphiphilic triblock copolymer PCL-b-PEG-b-PCL to the cationic phospholipid DOTAP is 20 mg: (0.5-2) mg; the organic solvent is selected from acetonitrile, A mixture of one or more of dichloromethane and chloroform;

[0036] Preferably, it also includes the st...

Embodiment 1

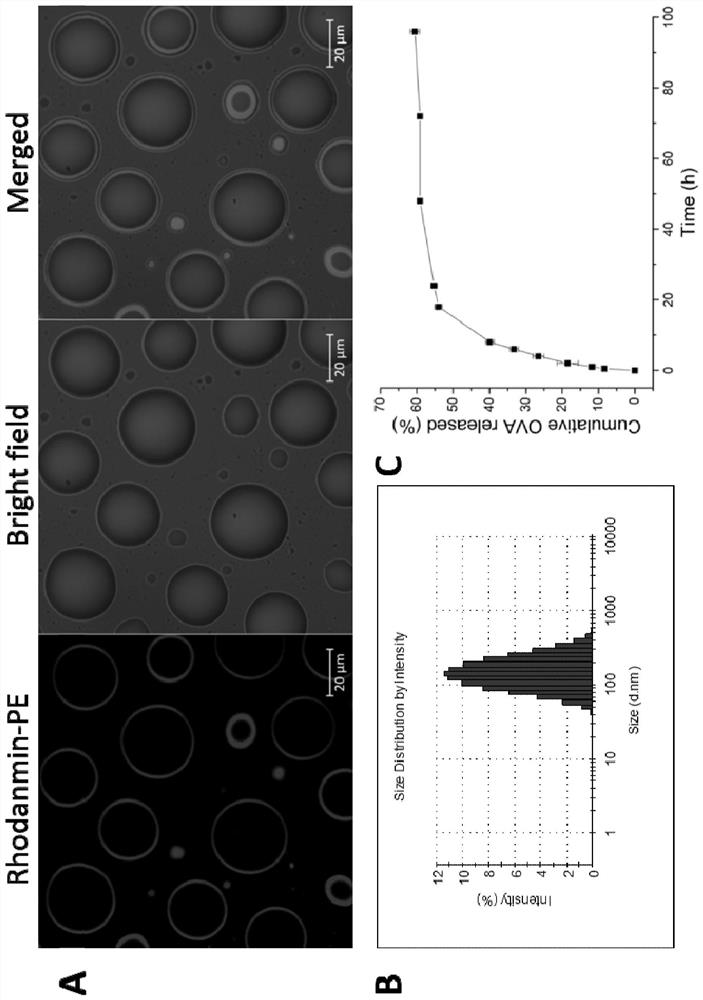

[0041] This embodiment provides a cationic phospholipid-polymer hybrid nanoparticle vaccine adjuvant loaded with antigen OVA. The preparation method comprises steps:

[0042] S1: Dissolve 20mg of amphiphilic triblock copolymer PCL-b-PEG-b-PCL and 1mg of cationic phospholipid DOTAP in dichloromethane, then remove the organic solvent by rotary evaporation, and form a uniform film on the bottle wall, Dry the residual solvent with nitrogen, then put it in a vacuum drying oven, and dry it in vacuum for 12-24 hours; among them, the molecular weight of the amphiphilic triblock copolymer PCL-b-PEG-b-PCL is 16000, and the PEG hydrophilic chain Segment mass percentage greater than 45%.

[0043] S2: Add 10 mL of double-distilled water to the dried product, hydrate at 65°C for 5 hours, oscillate and mix evenly, and then sonicate for 10 minutes in an ice bath to form a stable emulsion, filter the stable emulsion with a 0.45 μm filter membrane, collect the filtrate, and obtain Cationic pho...

Embodiment 2

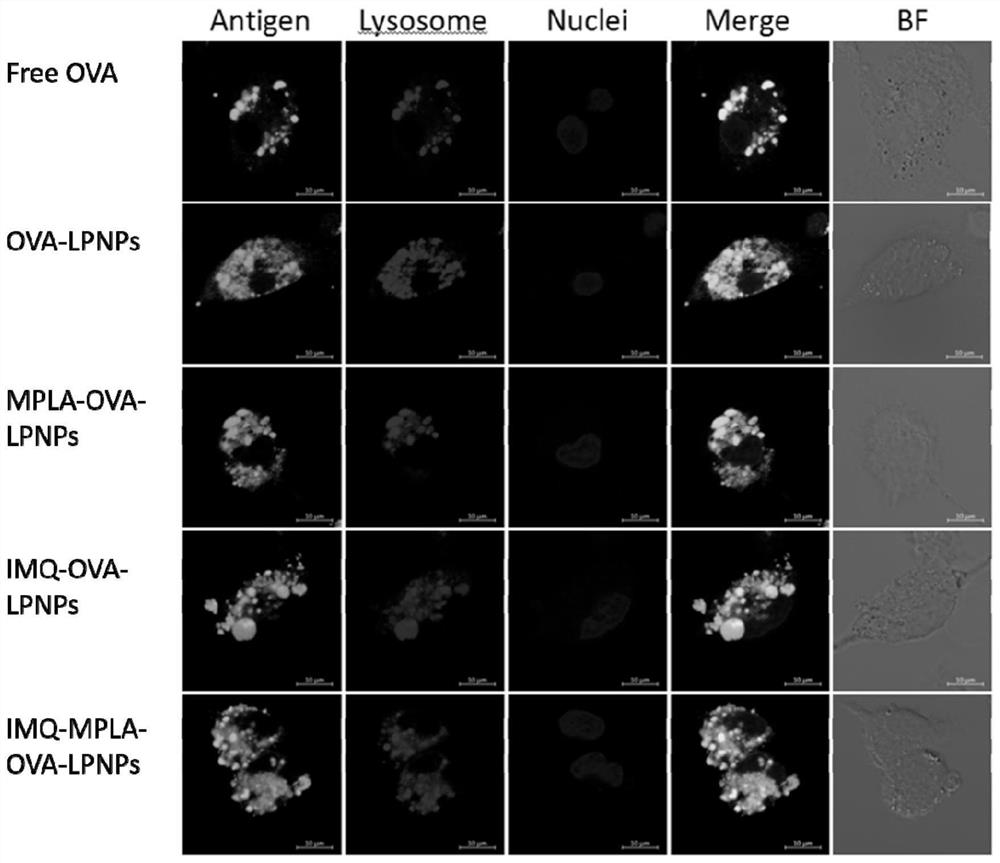

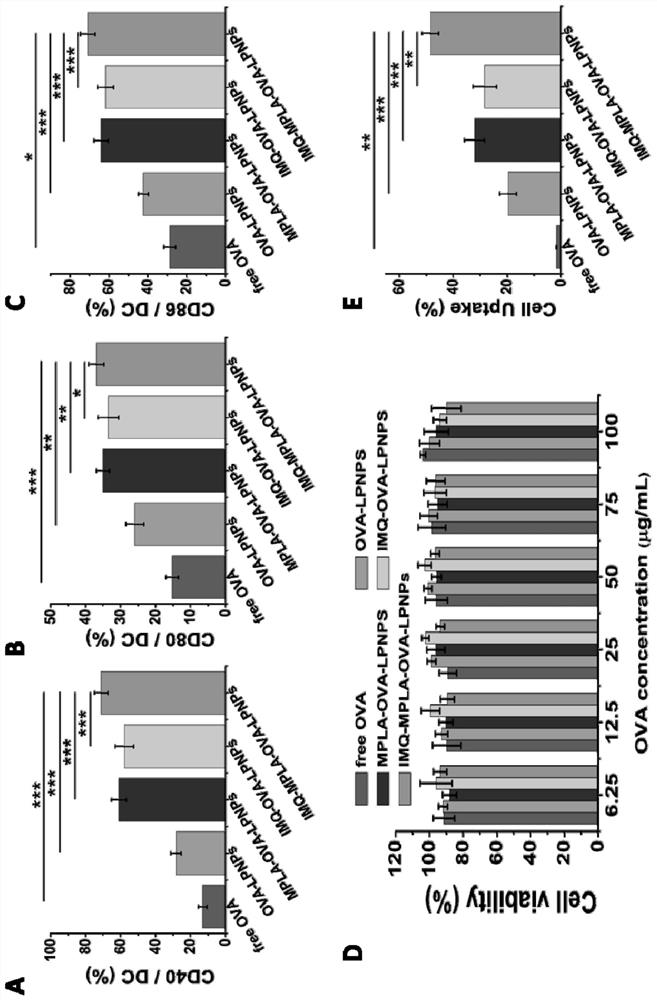

[0047] This embodiment provides a cationic phospholipid-polymer hybrid nanoparticle vaccine adjuvant loaded with TLR7 agonist IMQ and antigen OVA. The preparation method includes the steps:

[0048] S1: 20 mg amphiphilic triblock copolymer PCL-b-PEG-b-PCL, 1 mg cationic phospholipid DOTAP, and 100 μg TLR7 agonist IMQ were dissolved in dichloromethane, and then the organic solvent was removed by rotary evaporation, forming a layer a uniform film, dry the residual solvent with nitrogen, put it in a vacuum drying oven, and dry it in vacuum for 12 hours; wherein, the molecular weight of the amphiphilic triblock copolymer PCL-b-PEG-b-PCL is 16000, of which PEG The mass percentage of the hydrophilic segment is greater than 45%.

[0049] S2: Add 10 mL of double-distilled water to the dried product, hydrate at 65°C for 5 hours, oscillate and mix evenly, and then sonicate for 10 minutes in an ice bath to form a stable emulsion, filter the stable emulsion with a 0.45 μm filter membrane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com