Dyeing and anti-deformation processing method for sorghum straws

A sorghum stalk and treatment method technology, applied in wood treatment, pretreatment equipment, magnetic wood treatment, etc., can solve the problems of poor quality of weaving products, monotonous color of weaving handicrafts, monotonous color of sorghum straw, etc., and eliminate wetting and diffusion barrier, improve wetting and hydrophilic properties, and strong polymerization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

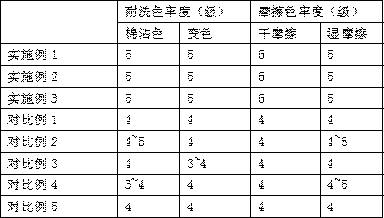

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a dyeing anti-deformation treatment method of sorghum stalks, the specific method is as follows:

[0018] (1) Trim the harvested sorghum stalks, immerse them in 2.3% sodium salicylate aqueous solution for 30 minutes, take out the drain, steam them at 88°C for 22 minutes, take them out, and cool them to get One-time processing of sorghum stalks;

[0019] (2) Submerge the first-time treated sorghum stalks in 3.4% magnesium stearate aqueous solution and boil on medium heat, then continue to simmer for 5 minutes, take out the drain, and steam for 34 minutes at a temperature of 140°C, take it out, and cool , to obtain secondary treatment of sorghum straw;

[0020] (3) Submerge the secondary treated sorghum stalks in the dyeing agent for 60 minutes and magnetize them, remove the leaching agent, and dry them at a temperature of 41-45°C;

[0021] The dyeing agent is made of the following raw materials in parts by weight: 23.4 parts ...

Embodiment 2

[0027] In the embodiment of the present invention, a dyeing anti-deformation treatment method of sorghum stalks, the specific method is as follows:

[0028] (1) Trim the harvested sorghum stalks, immerse them in 2.5% sodium salicylate aqueous solution for 35 minutes, take out the drain, steam them for 25 minutes at a temperature of 91°C, take them out, and cool them to obtain One-time processing of sorghum stalks;

[0029] (2) Submerge the first-time treated sorghum stalks in 3.6% magnesium stearate aqueous solution and boil on medium heat, then continue to simmer for 6 minutes, take out the drain, and steam for 37 minutes at a temperature of 144°C, take it out, and cool , to obtain secondary treatment of sorghum straw;

[0030] (3) Soak the secondary treated sorghum stalks in the dyeing agent for 65 minutes and magnetize them, remove the leaching agent, and dry them at a temperature of 43°C;

[0031] The dyeing agent is made of the following raw materials in parts by weight...

Embodiment 3

[0037] In the embodiment of the present invention, a dyeing anti-deformation treatment method of sorghum stalks, the specific method is as follows:

[0038] (1) Trim the harvested sorghum stalks, immerse them in 2.7% sodium salicylate aqueous solution for 40 minutes, take out the drain, steam them at 94°C for 28 minutes, take them out, and cool them to get One-time processing of sorghum stalks;

[0039] (2) Submerge the first-time treated sorghum stalks in 3.8% magnesium stearate aqueous solution and boil on medium heat, then continue to simmer for 7 minutes, drain and take out, steam for 40 minutes at a temperature of 148°C, take out, and cool , to obtain secondary treatment of sorghum straw;

[0040] (3) Submerge the secondary treated sorghum stalks in the dyeing agent for 70 minutes, then magnetize them, remove the leaching agent, and dry them at a temperature of 41-45°C;

[0041]The dyeing agent is made of the following raw materials in parts by weight: 24.8 parts of cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com