In situ preparation of 3D carbide nanowire arrays by immersion pyrolysis and magnetic pulling of precursors

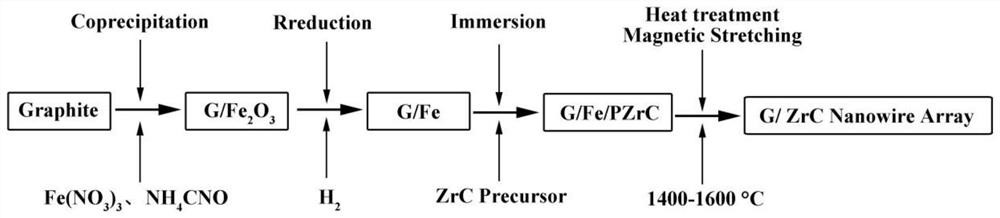

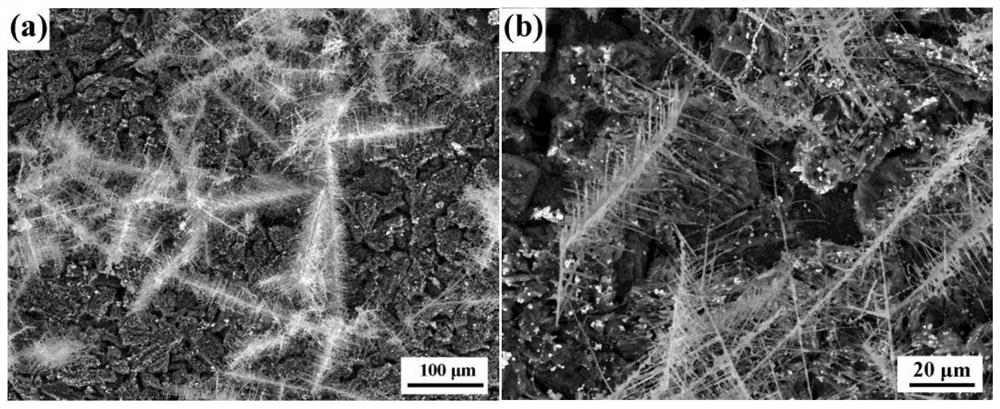

A technology of nanowire array and impregnation cracking, which is applied in the field of precursor impregnation cracking and magnetic pulling method to prepare 3D carbide nanowire array in situ, which can solve the limitation of one-dimensional carbide nanomaterial design and one-dimensional nanomaterial growth Uncontrollable direction and other problems, to achieve the effect of improving anti-oxidation and anti-ablation performance, controllable growth direction, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

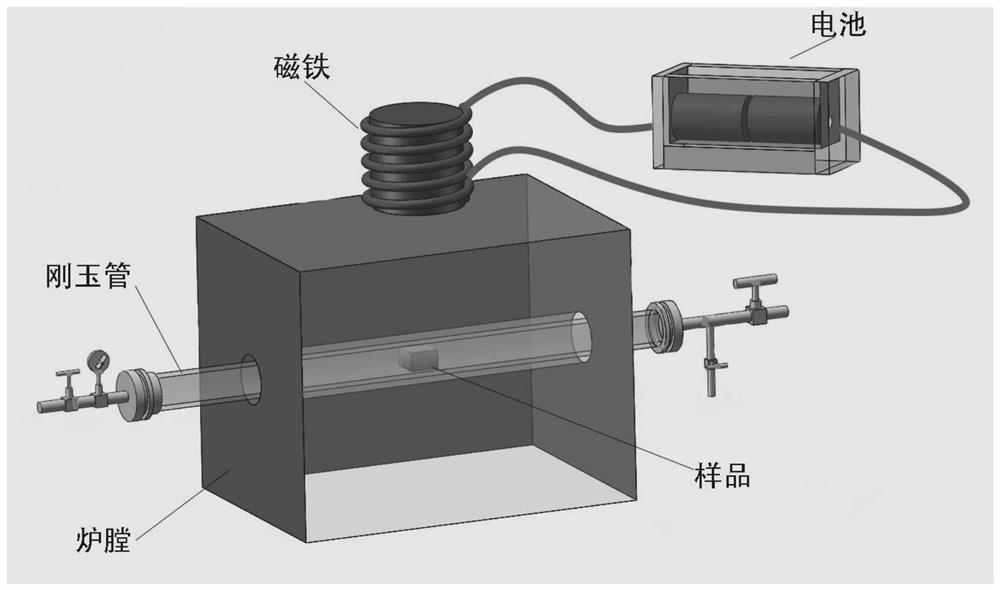

Method used

Image

Examples

Embodiment 1

[0050] The high-purity graphite sheet was cut into a sheet of 20 × 20 × 5 mm by a cutter, and the graphite sheet was placed in a beaker containing alcohol, and then washed in an ultrasonic cleaning device for 30 min. It is weighed in the bicycle of nerves and the nine-water nitrate, which is dissolved in the beaker with deionized water, wherein the molar ratio of urea and nine-water nitrate is 3: 2, magnetic force for 30 min, and then move the solution into the graphite sheet. Polytetrafluorine liner, blocking kettle. The reactor was placed in an oven, the maximum temperature of the oven was 120 ° C, and the constant temperature was 1 h. The graphite sheet in the reactor was taken, and it was dried, and the temperature of the hydrogen reduction was placed in the horizontal heat treatment furnace, and the reduction time was 1 h, the reduction time was transferred simultaneously, the flow ratio of the two gases To 2: 1. When the temperature drops to room temperature, a large amount ...

Embodiment 2

[0054] The high-purity graphite sheet was cut into a sheet of 20 × 20 × 5 mm with a cutting machine, and the graphite sheet was placed in a beaker containing alcohol, and then washed in an ultrasonic cleaning device for 60 min. It is weighed with a number of glycin and nine-water nitrate, which is dissolved in the beaker with deionized water, wherein the molar ratio of urea and nine-water nitrate is 3: 2, magnetic force is stirred for 60 min, and then the solution is moved into the graphite sheet. Polytetrafluorine liner, blocking kettle. The reactor was placed in an oven, and the maximum temperature of the oven was 180 ° C, and the temperature was 3 h. The graphite sheet in the reactor was taken, and it was dried, and the temperature of the hydrogen reduction was 700 ° C in the horizontal heat treatment furnace, and the reduction time was 3 h, the hydrogen gas was simultaneously introduced, and the flow rate ratio of the two gases. To 2: 1. When the temperature drops to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com