Safe and simple method for preparing double-doped nitrogen and phosphor carbon quantum dots

A dual doping and quantum dot technology, which is applied in chemical instruments and methods, measuring devices, fluorescence/phosphorescence, etc., can solve the problems of high toxicity of nitrogen doping agents, poor fluorescence performance, cumbersome preparation of carbon quantum dots, etc., and achieve solubility Good, safe reaction, large-scale preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

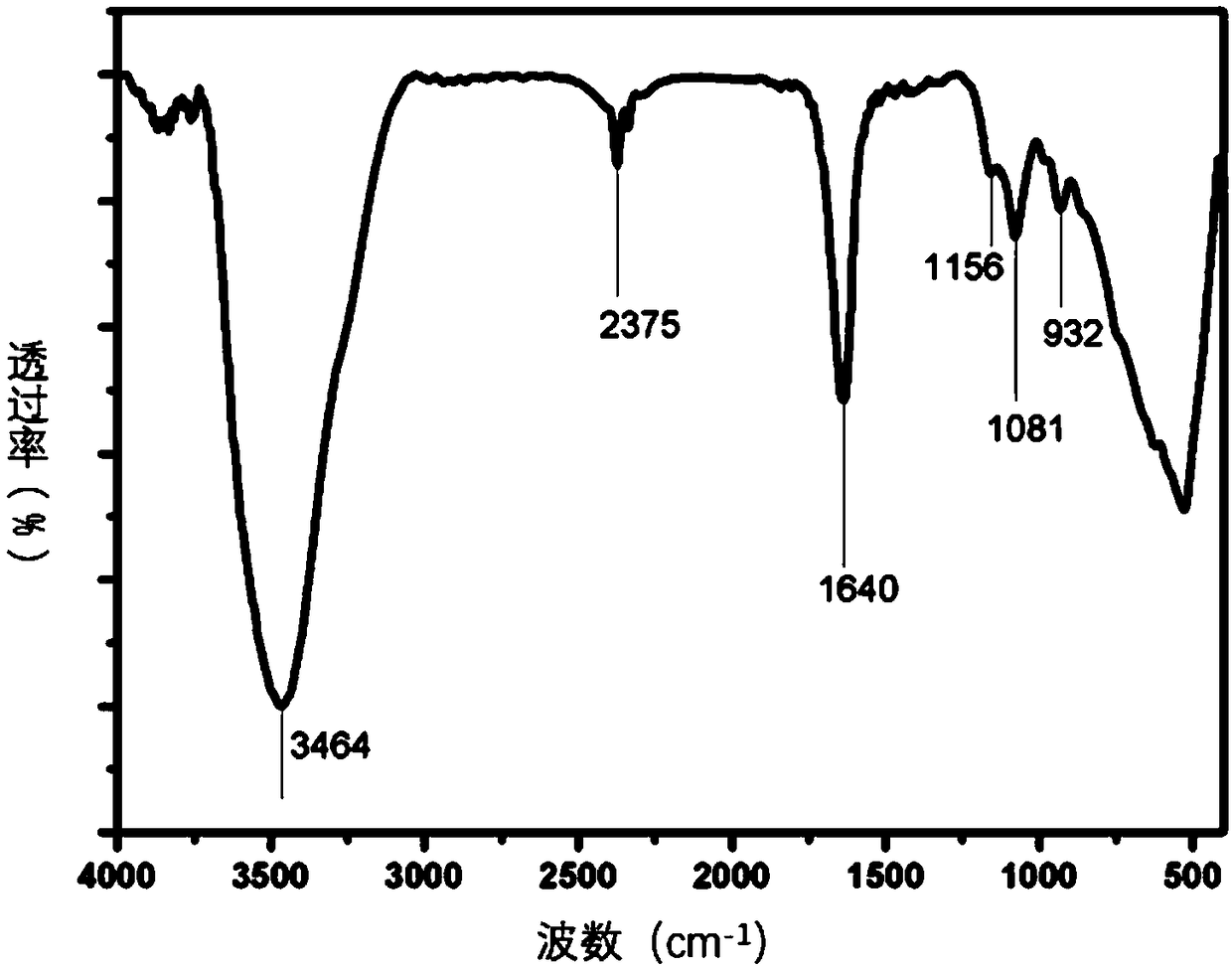

[0035] Preparation of tryptophan-carbon dots:

[0036] Weigh 0.005mol tryptophan and 0.005mol glucose into a beaker, add 5ml deionized water, add 5ml 80% phosphoric acid solution by mass, stir until completely dissolved, and form a clear and transparent solution;

[0037] The beaker was placed in an ultrasonic machine for sonication for 2 h, and the ultrasonic frequency was 40 Hz. There was no change in the appearance of the solution after sonication.

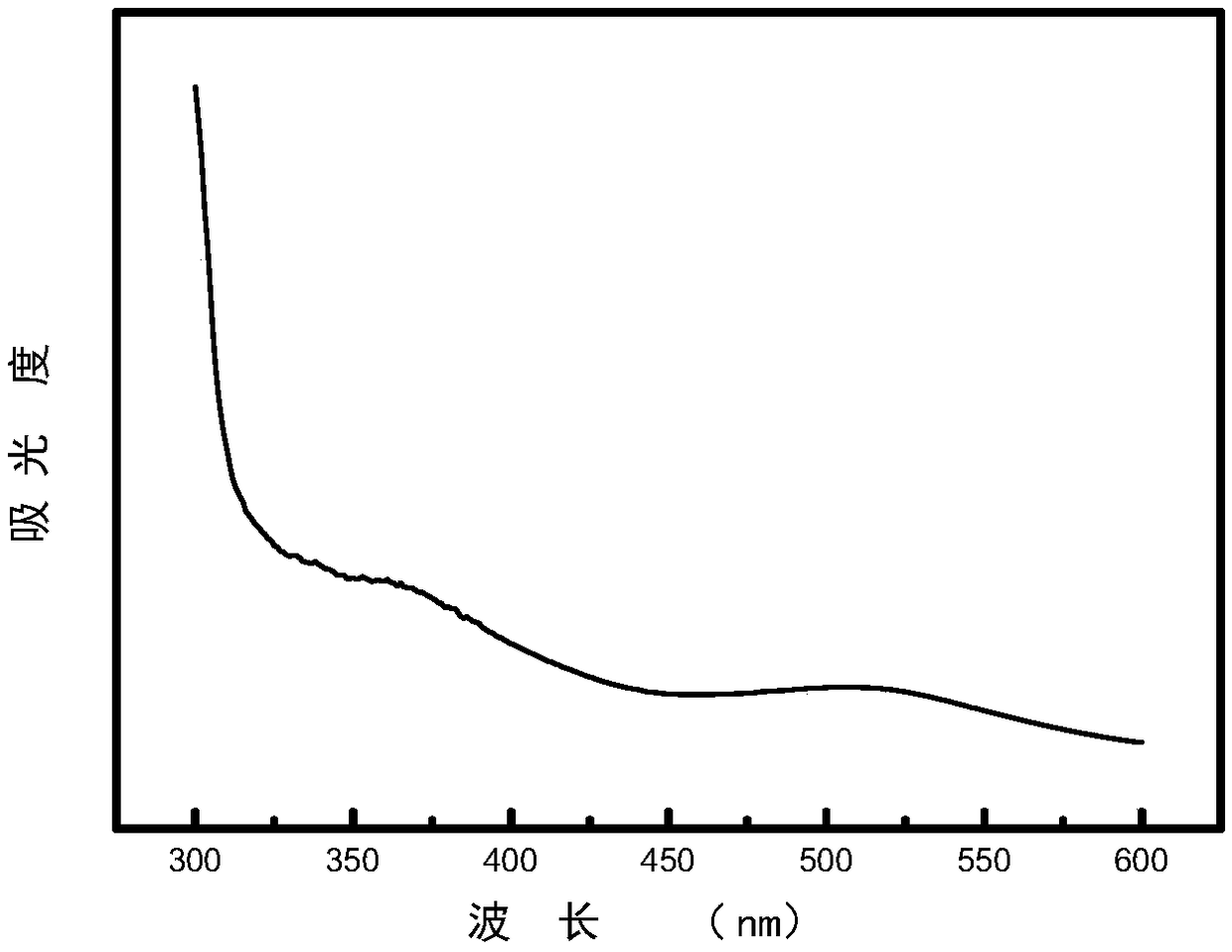

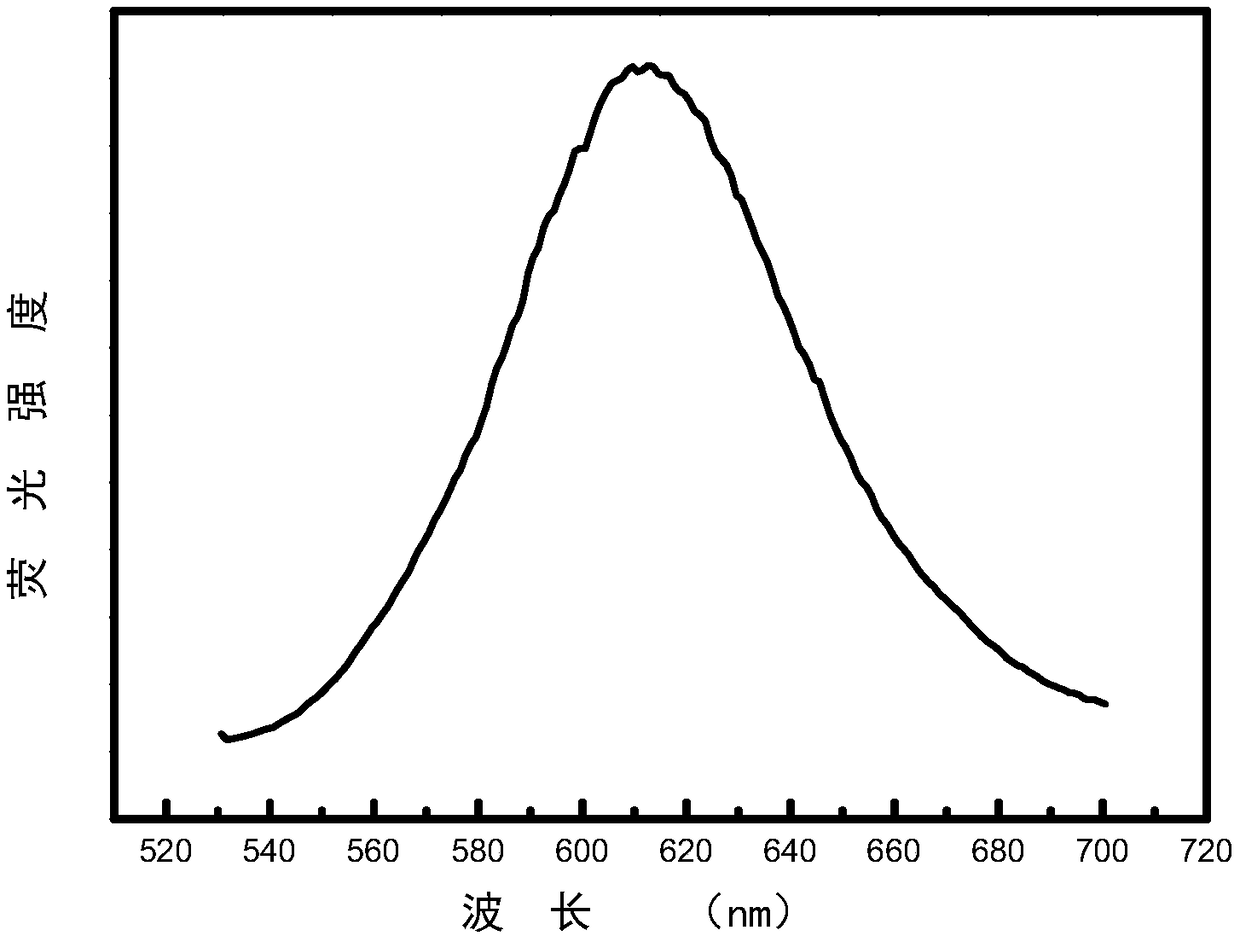

[0038] The solution was transferred to a 25ml round-bottomed flask, heated to reflux in a constant temperature heating magnetic stirrer, the temperature was kept at 90 °C, and heated for 5 hours. During the heating process, the color of the solution gradually changed from clear and transparent to red, and finally to purple. After heating, cool to room temperature. After proper dilution, the carbon dots are red in sunlight, and emit orange-red fluorescence under 365nm ultraviolet light.

[0039] Centrifuge at 10000rmp for 10m...

Embodiment 2

[0046] Preparation of glutamic acid-carbon dots:

[0047] Weigh 0.0005mol glutamic acid and 0.005mol glucose into a beaker, add 5ml deionized water, then pour 5ml phosphoric acid solution with a mass fraction of 85%, stir until completely dissolved to form a clear and transparent solution;

[0048] The beaker was placed in an ultrasonic machine for sonication for 2 h, and the ultrasonic frequency was 50 kHz.

[0049] The solution was transferred to a 25ml round-bottomed flask, heated to reflux in a constant temperature heating magnetic stirrer, the temperature was kept at 150 °C, and heated for 1 hour. During the heating process, the color of the solution gradually changed from clear and transparent to brown. After heating, cool to room temperature. The obtained high-concentration carbon dots are light yellow under sunlight and yellow under 365nm ultraviolet light after dilution.

[0050] Centrifuge at 20,000 rmp for 10 min to remove large particles of impurities, and then dia...

Embodiment 3

[0052] Preparation of aspartic acid-carbon dots:

[0053] Weigh 0.005mol aspartic acid and 0.005mol citric acid monohydrate into a beaker, add 5ml deionized water, add 5ml phosphoric acid solution with a mass fraction of 90%, stir until completely dissolved, and form a clear and transparent solution;

[0054] The beaker was placed in an ultrasonic machine for sonication for 2 h, and the ultrasonic frequency was 60 kHz. There was no change in the appearance of the solution after sonication.

[0055] The solution was transferred to a 25ml round-bottomed flask, heated to reflux in a constant temperature heating magnetic stirrer, the temperature was kept at 120 °C, and heated for 2 hours. During the heating process, the color of the solution gradually changed from clear and transparent to red, and finally to black-brown. After heating, cool to room temperature. When properly diluted, the carbon dots are brown in sunlight and blue in 365nm UV light.

[0056] Centrifuge at 30000r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com