Coal combustion improver and preparation method and application thereof

A combustion aid and coal-fired technology, which is applied in the field of coal-fired combustion aids and its preparation, can solve the problems of short action time of the combustion system, difficulty in controlling the concentration, and limited actual efficacy, and achieve shortened ignition time, simple and easy process, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

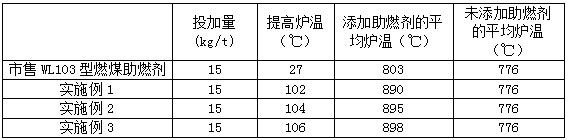

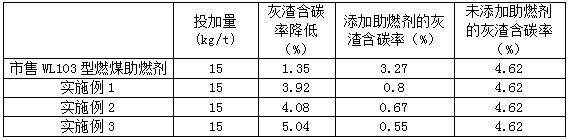

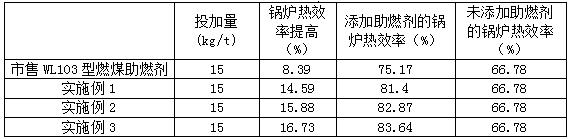

Embodiment 1

[0035] After fully mixing sodium bicarbonate, ammonium bicarbonate and light calcium carbonate according to the mass ratio of 1:1:1, dry at 80°C for 30 minutes to make a leavening agent; mix potassium permanganate and potassium chlorate according to the mass ratio 2:2 After fully mixing, dry at 20°C for 20 minutes to make an oxidizing agent; after fully mixing manganese dioxide, ferric chloride and aluminum oxide according to the mass ratio of 2:1:1, dry at 20°C for 20 minutes Minutes to make a catalyst; Dicyclopentadienyl iron and 2-methylcyclopentadiene manganese tricarbonyl manganese are fully mixed according to the mass ratio of 1:1, and then dried at 20°C for 20 minutes to make a stabilizer; Calcium hydroxide, calcium carbonate, calcium chloride, ferrous nitrate and ferrous sulfate are fully mixed according to the mass ratio of 1:1:0.5:0.5:0.5, and then dried at 60°C for 30 minutes to make a desulfurizer; After the alkyl alcohol ether, phosphoric acid ester and chlorinate...

Embodiment 2

[0037] After fully mixing sodium bicarbonate, ammonium bicarbonate and light calcium carbonate according to the mass ratio of 2:2:1.5, dry at 95°C for 45 minutes to make a leavening agent; mix potassium permanganate and potassium chlorate according to the mass ratio 2.5:2.5 After fully mixing, dry at 25°C for 25 minutes to make an oxidizing agent; after fully mixing manganese dioxide, ferric chloride and aluminum oxide according to the mass ratio of 2.5:1.5:1.5, dry at 25°C for 25 Minutes to make a catalyst; Dicyclopentadienyl iron and 2-methylcyclopentadiene manganese tricarbonyl manganese are fully mixed according to the mass ratio of 1.5:1.5, and then dried at 25°C for 25 minutes to make a stabilizer; Calcium hydroxide, calcium carbonate, calcium chloride, ferrous nitrate and ferrous sulfate are fully mixed according to the mass ratio of 1.5:1.5:0.75:0.75:0.75, and dried at 90°C for 45 minutes to make a desulfurizer; After the alkyl alcohol ether, phosphoric acid ester and ...

Embodiment 3

[0039]Sodium bicarbonate, ammonium bicarbonate and light calcium carbonate are fully mixed according to the mass ratio of 3:3:2, and dried at 110°C for 60 minutes to make a leavening agent; potassium permanganate and potassium chlorate are mixed according to the mass ratio After fully mixing 3:3, dry at 30°C for 30 minutes to make an oxidizing agent; after fully mixing manganese dioxide, ferric chloride and alumina according to the mass ratio of 3:2:2, dry at 30°C for 30 minutes Minutes to make a catalyst; Dicyclopentadienyl iron and 2-methylcyclopentadiene manganese tricarbonyl manganese are fully mixed according to the mass ratio of 2:2, and then dried for 30 minutes at 30°C to make a stabilizer; Calcium hydroxide, calcium carbonate, calcium chloride, ferrous nitrate and ferrous sulfate are fully mixed according to the mass ratio of 2:2:1:1:1, and dried at 120°C for 60 minutes to make a desulfurizer; After the alkyl alcohol ether, phosphoric acid ester and chlorinated hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com