Tubular bacterial nanocellulose material and preparation method and application thereof

A technology of nanocellulose and bacteria, applied in biochemical equipment and methods, methods based on microorganisms, medical science, etc., can solve the problems of radial delamination, easy adhesion of platelets, uneven structure of composite materials, etc., and achieve blood The effect of good compatibility and excellent anticoagulant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Prepare 100mL of liquid medium (50g / L fructose, 5g / L peptone, 3g / L yeast powder) in a 250mL Erlenmeyer flask, sterilize at 115°C for 30min under high temperature and high pressure, cool to room temperature, and inoculate Gluconacetobacter xylinus ( Current name: Komagataeibacter xylinus) ATCC 23770 strain, or G. xylinus ATCC 23766, or G. xylinus ATCC 23769, 30 ° C, 100 rpm shaking culture for 24 hours, to obtain a fermented broth with vigorous strain.

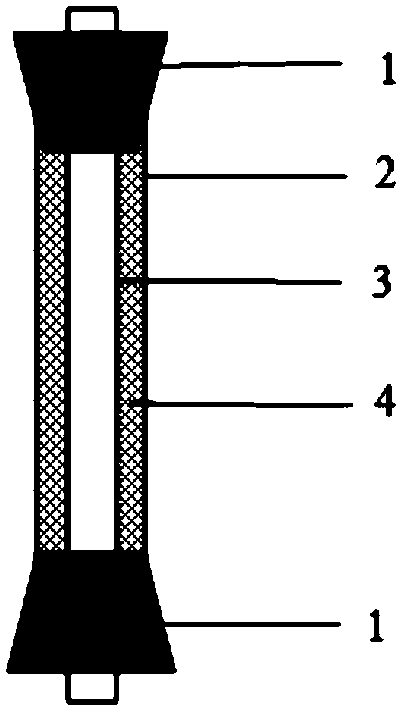

[0039] (2) Prepare a glass rod with a length of 12 mm and a diameter of 3 mm, a silicone tube with a length of 12 mm, an inner diameter of 8 mm, and a wall thickness of 0.5 mm, and two cylindrical hollow silicone plugs with large and small heads. The diameter of the large end is 10 mm, and the diameter of the small end is 5mm, the hollow diameter is 3mm. Wash and dry, put the glass rod and the silicone tube coaxially in the lumen of the silicone tube, a hollow cylindrical cavity is formed between the glass rod and th...

Embodiment 2

[0043] (1) Prepare 100mL of liquid medium (100g / L glucose, 5g / L peptone, 3g / L yeast powder), place it in a 250mL Erlenmeyer flask, sterilize at 115°C for 30min, cool to room temperature, and The strain ATCC700178 was inoculated in a clean workbench, and cultured at 30° C. and 100 rpm on a shaker at a constant temperature for 24 hours to obtain a fermentation broth.

[0044] (2) Prepare a steel rod with a length of 12mm and a diameter of 2mm, a silicone tube with a length of 12mm, an inner diameter of 6mm, and a wall thickness of 0.5mm, and two cylindrical hollow silicone plugs with large and small heads. The diameter of the large end is 8mm, and the diameter of the small end is 5mm, the hollow diameter is 2mm. After washing and drying, the steel rod and the silicone tube are coaxially placed in the lumen of the silicone tube. A hollow cylindrical cavity is formed between the steel rod and the silicone tube. The opening of the silicone tube is sealed by a cylindrical hollow sil...

Embodiment 3

[0048] (1) Prepare 100mL of liquid medium (100g / L glucose, 5g / L peptone, 3g / L yeast powder), put it in a 250mL Erlenmeyer flask, sterilize at 115℃ for 30min, cool to room temperature, and inoculate ZCY The strain of Gluconacetoacetobacter xylinum ATCC23770 was cultured at 30° C. and shaken at 100 rpm for 24 hours to obtain a fermented liquid with vigorous strain.

[0049] (2) Prepare a glass rod with a length of 12 mm and a diameter of 3 mm, a silicone tube with a length of 12 mm, an inner diameter of 8 mm, and a wall thickness of 0.5 mm, and two cylindrical hollow silicone plugs with large and small heads. The diameter of the large end is 10 mm, and the diameter of the small end is 5mm, the hollow diameter is 3mm. After washing and drying, the glass rod and the silicone tube are coaxially placed in the lumen of the silicone tube. A hollow cylindrical cavity is formed between the glass rod and the silicone tube. The opening of the silicone tube passes through a cylindrical hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com