A method for preparing inorganic-organic flexible composite materials with magnetoelectric coupling properties

A composite material, magnetoelectric coupling technology, applied in material selection, metal material coating process, electromagnetic device manufacturing/processing, etc., to achieve the effects of good pressure resistance, easy implementation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

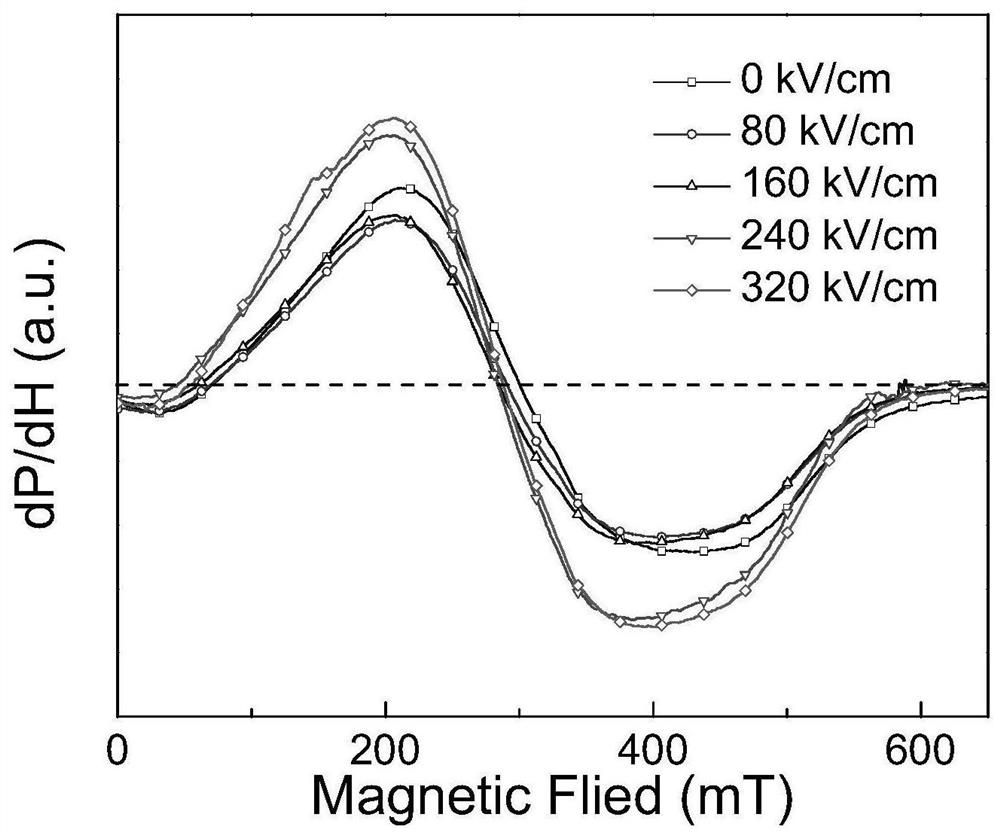

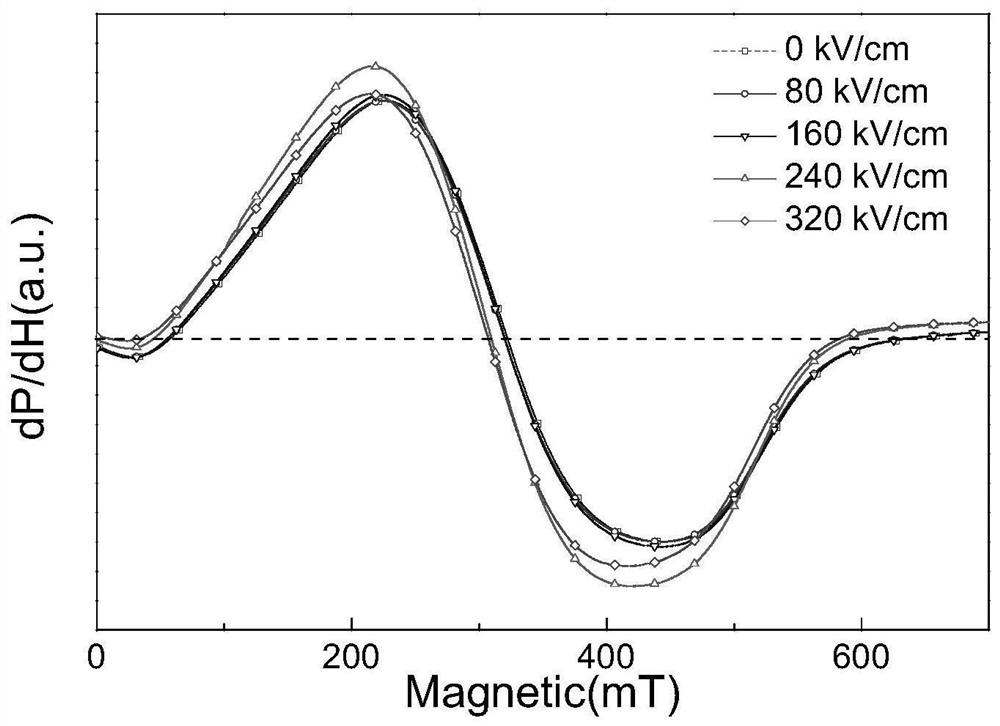

Image

Examples

Embodiment 1

[0032] A method for preparing an inorganic-organic composite flexible multiferroic material, comprising the following steps:

[0033] a. Slide preparation:

[0034] Clean the glass slides required for the experiment in the following order: ultrasonically clean with acetone for 10 minutes, pour out the acetone, wash with absolute ethanol for 10 minutes, pour out the absolute ethanol, and repeat ultrasonic cleaning with deionized water for 3 times, each 5 minutes each time. Finally, dry it with nitrogen gas.

[0035] b. Disperse PVDF-TrFE powder in dimethylformamide at a mass ratio of 1:10, and filter the PVDF solution after magnetic stirring for 8 hours. The mass is PVDF-TrFE powder mass 1% Fe 3 o 4 After the nanoparticles were dispersed in the PVDF solution, ultrasonic oscillation was continued for 4 hours, and the solution was placed in a vacuum pump to evacuate for 5 minutes.

[0036] c. Evenly drop the solution evenly dispersed by ultrasonic vibration on the glass slid...

Embodiment 2

[0041] A method for preparing an inorganic-organic composite flexible multiferroic material, comprising the following steps:

[0042] a. Slide preparation:

[0043]Clean the glass slides required for the experiment in the following order: ultrasonically clean with acetone for 10 minutes, pour out the acetone, wash with absolute ethanol for 10 minutes, pour out the absolute ethanol, and repeat ultrasonic cleaning with deionized water for 3 times, each 5 minutes each time. Finally, dry it with nitrogen gas.

[0044] b. Disperse PVDF-TrFE powder in dimethylformamide at a mass ratio of 1:10, and filter the PVDF solution after magnetic stirring for 8 hours. The mass is PVDF mass 10% Fe 3 o 4 After the nanoparticles were dispersed in the PVDF solution, ultrasonic oscillation was continued for 4 hours, and the solution was placed in a vacuum pump to evacuate for 5 minutes.

[0045] c. Evenly drop the solution evenly dispersed by ultrasonic vibration on the glass slide, remove th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com