A kind of nanocomposite material and its preparation method and application

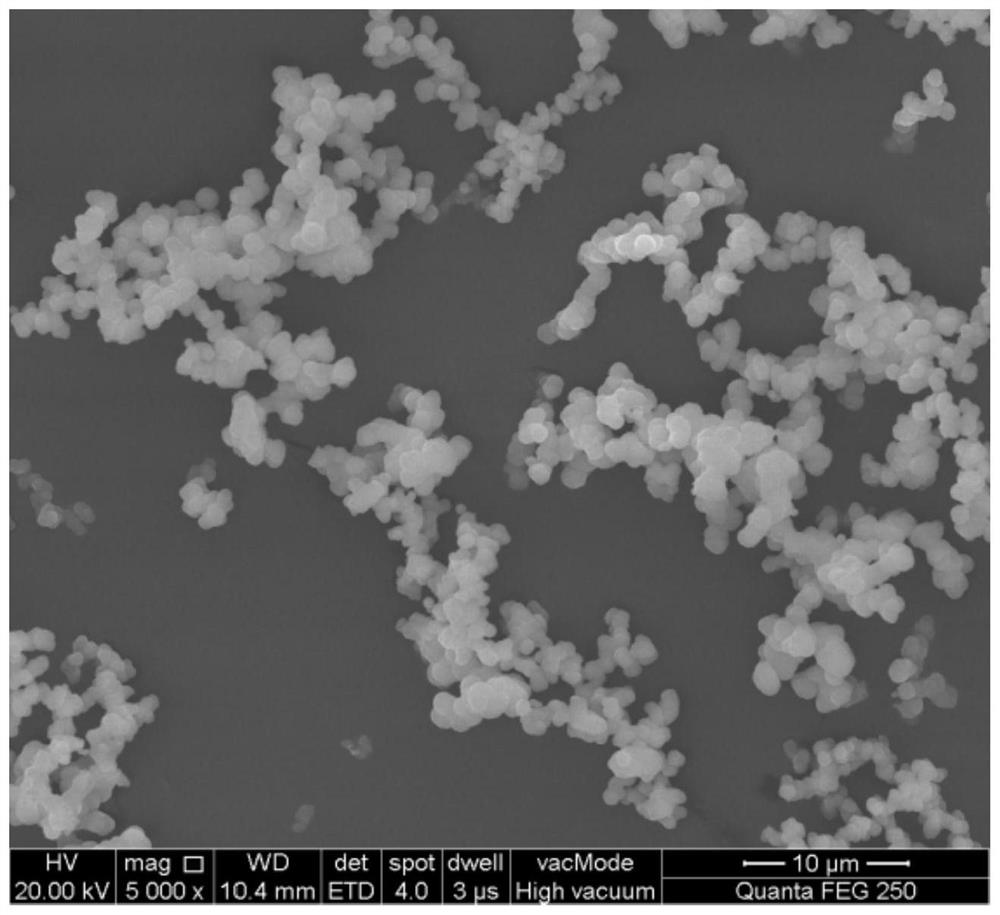

A nano-composite material and nano-zinc oxide technology, which is applied in the field of nano-composite materials and their preparation, can solve the problems of electrode deformation, dendrite growth, deformation of zinc anode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

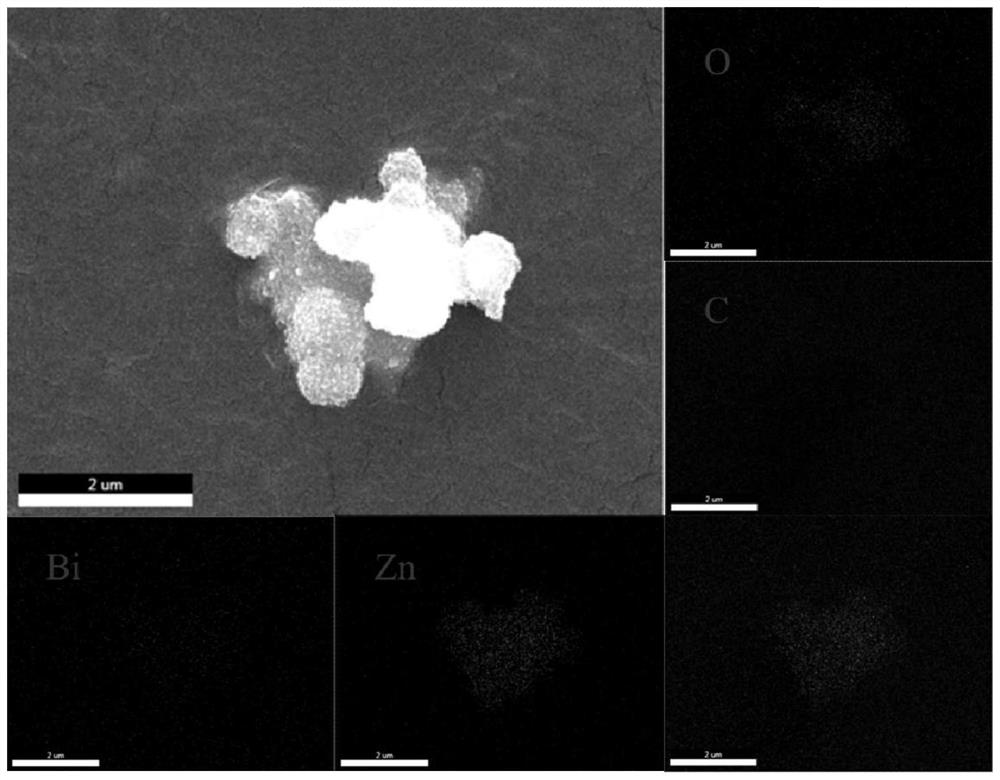

Embodiment 1

[0055] (1) Weigh 2g of zinc acetate powder and 120mgBi(NO 3 ) 3 ·5H 2 O was added to 50ml of ethylene glycol solution, stirred for 1h to fully dissolve the two, and then 1g of glucose was added to the mixed solution as a carbon source to obtain a transparent mixed solution.

[0056] (2) Pour the obtained transparent mixed solution into a hydrothermal kettle, place it in a high-temperature oven and adjust the heating rate to 10°C / min, and after hydroheating at a temperature of 150°C for 3 hours, use water cooling to rapidly reduce it to room temperature.

[0057] (3) Filter and separate the obtained hydrothermal product to obtain a brown precursor powder, then put the precursor into 100ml of ethanol and sonicate for 10 minutes, repeatedly wash and filter three times, and then put the precursor in an oven to dry for 8 hours stand-by.

[0058] (4) Finally, put the obtained precursor powder into an Ar-protected high-temperature resistance furnace, maintain a heating rate of 4°...

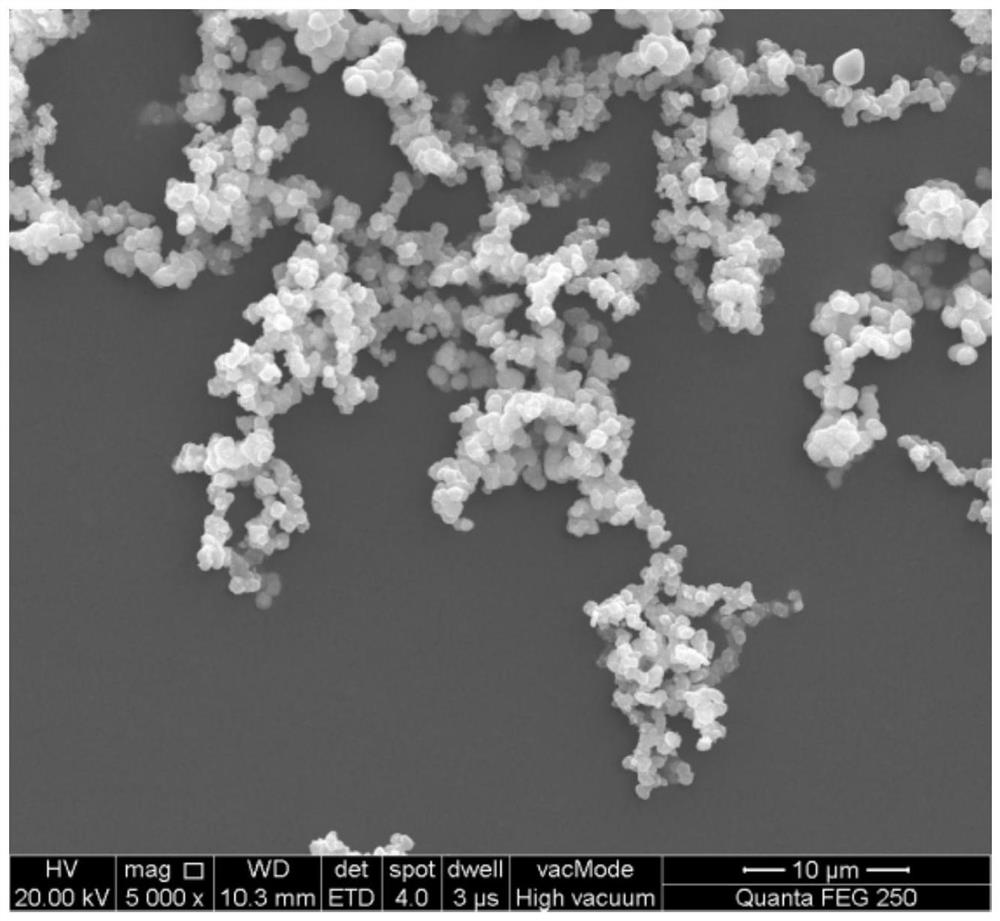

Embodiment 2

[0065] (1) Weigh 4g of zinc acetate powder and 250mgIn(NO 3 ) 3 Add it into 70ml of glycerol solution, stir for 1.5h to fully dissolve the two, and then add 1.3g of fructose as a carbon source to the mixed solution to obtain a transparent mixed solution.

[0066] (2) Pour the obtained transparent mixed solution into a hydrothermal kettle, place it in a high-temperature oven and adjust the heating rate to 14°C / min, and after hydroheating at a temperature of 160°C for 5 hours, use water cooling to rapidly reduce it to room temperature.

[0067] (3) Filter and separate the obtained hydrothermal product to obtain brown precursor powder, then put the precursor into 100ml of deionized water and ultrasonic for 15min, wash and filter three times repeatedly, then put the precursor into an oven to dry for 10h stand-by.

[0068] (4) Finally, put the obtained precursor powder into N 2 In a protected high-temperature resistance furnace, maintain a heating rate of 5° C. / min, and calcina...

Embodiment 3

[0076] (1) Weigh 4.5g of zinc acetate powder and 300mg of SnCl in proportion 2 2H 2 O was added to 50ml of ethylene glycol solution, stirred for 2h to fully dissolve the two, and then 2g of soluble starch was added to the mixture as a carbon source to obtain a transparent mixed solution.

[0077] (2) Pour the obtained transparent mixed solution into a hydrothermal kettle, place it in a high-temperature oven and adjust the heating rate to 18°C / min, and after 7 hours of hydroheating at a temperature of 180°C, use water cooling to rapidly reduce it to room temperature.

[0078] (3) Filter and separate the obtained hydrothermal product to obtain a brown precursor powder, then put the precursor into 100ml of methanol and ultrasonicate for 20min, wash and filter three times repeatedly, and then put the precursor into an oven to dry for 10h stand-by.

[0079] (4) Finally, put the obtained precursor powder into a high-temperature resistance furnace protected by He, maintain a heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com