Novel nano-HDDA-EP system IPNS composite coating as well as preparation method and application thereof

A composite coating and surface modification nanotechnology, applied in the field of steel anti-corrosion coatings, can solve problems such as limited organic coatings, rust and corrosion of steel, threats to people's lives, etc., to achieve good mechanical properties, good corrosion resistance, and avoid wire damage The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method comprises steps:

[0034] S101: Fully grind the nano silicon dioxide, and then dissolve it in xylene;

[0035] S102: under stirring, add silane coupling agent KH-560 to the mixture obtained in S101, and then stir for 25 to 35 minutes;

[0036] S103: After the stirring is completed, react in a constant temperature water bath at 70-90°C for 5-7 hours;

[0037] S104: Filter the transparent colloidal substance after the reaction, add drier DMP-30 to the filtered product; dry at 85-95° C. for 0.5-1.5 hours to obtain surface-modified nano silicon dioxide.

[0038] The present invention also provides a composite coating, the raw material components include: 40-45 parts by weight of E-44 epoxy resin, 6-8 parts by weight of talcum powder (filler), polyamide 650 (low molecular polyamide substance) 16 ~17 parts by weight, 12 parts by weight of butyl acetate (ester organic solvent), 12 parts by weight of xylene (aromatic hydrocarbon solvent), 0.8 to 0.9 par...

Embodiment 1

[0045] This embodiment provides a surface-modified nano-silica. The raw material components are calculated by mass percentage, including: 4.9% nano-silica, 2.5% silane coupling agent KH-560, 1.68% drier DMP-30, The balance is xylene.

[0046] The preparation method comprises steps:

[0047] S101: Fully grind the nano silicon dioxide, and then dissolve it in xylene;

[0048] S102: under stirring, add silane coupling agent KH-560 to the mixture obtained in S101, and then stir for 30 minutes;

[0049] S103: After the stirring is completed, react in a constant temperature water bath at 80°C for 6 hours;

[0050] S104: Filter the transparent colloidal substance after the reaction, and add a drier DMP-30 to the filtered product; dry at 90° C. for 1 hour to obtain surface-modified nano-silica.

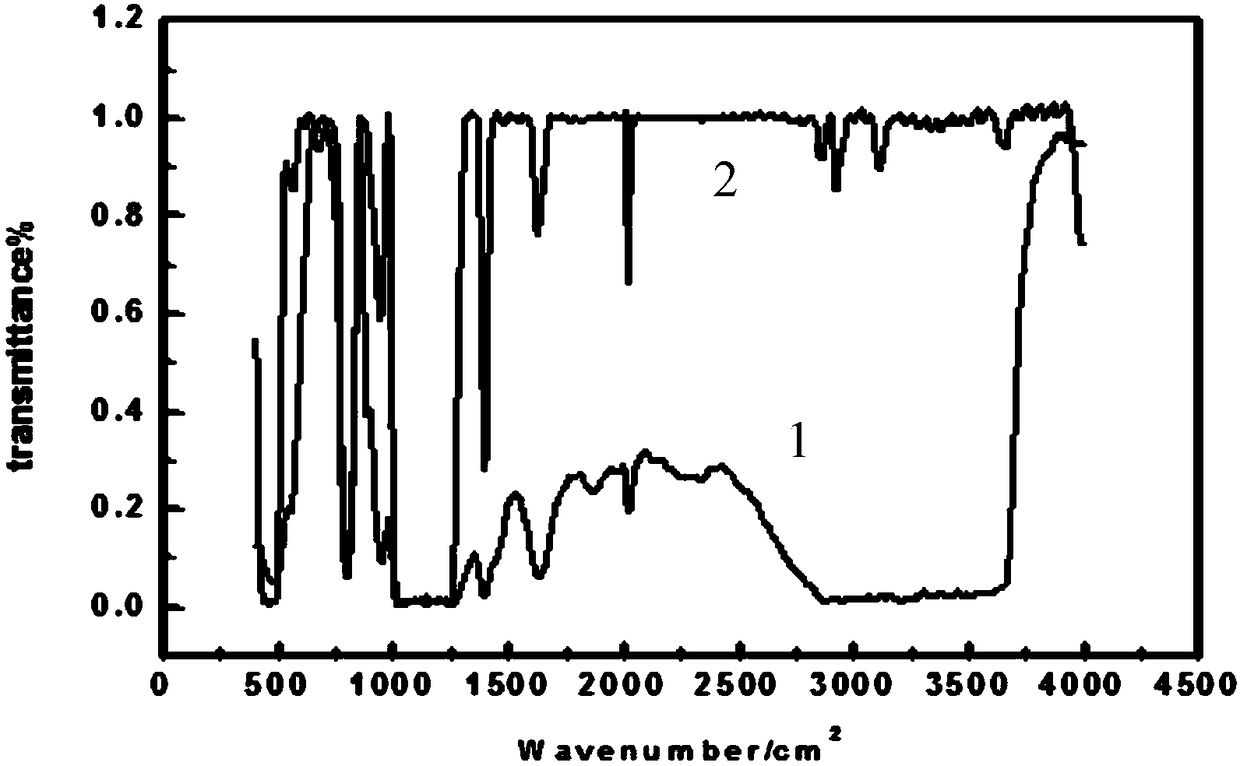

[0051] The grafting rate of nano-silica after surface modification can reach 0.067066, and the Fourier transform infrared spectrum analysis picture is as follows figure 1 shown.

[0052]...

Embodiment 2

[0054] This embodiment provides a kind of composite coating, and raw material component comprises: E-44 epoxy resin 42 weight parts, talcum powder (filler) 7 weight parts, polyamide 650 (low molecular polyamide substance) 16.8 weight parts, acetic acid 12 parts by weight of butyl ester (ester organic solvent), 12 parts by weight of xylene (aromatic hydrocarbon solvent), 0.84 part by weight of surface-modified nano-silica, 0.02 part by weight of dibenzoyl peroxide, 1,6-hexyl 5.88 parts by weight of diol diacrylate (HDDA), 0.4 parts by weight of leveling agent and 0.10 parts by weight of defoamer.

[0055] The preparation method of composite coating comprises steps:

[0056] S1: Mix E-44 epoxy resin and polyamide 650 (low molecular weight polyamide) and stir thoroughly;

[0057] S2: Add 1,6-hexanediol diacrylate (HDDA) to the mixture obtained in S1, then add dibenzoyl peroxide, and stir thoroughly;

[0058] S3: React the mixture obtained in S2 in a water bath at 60°C for 1 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com