Aluminum ion battery and preparation method thereof

A technology for aluminum ion batteries and ionic liquids, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of polyaniline/ordered mesoporous carbon composite aluminum ion battery cathode materials that have not been reported, and achieve good results. The effects of insulation, simple preparation method, and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

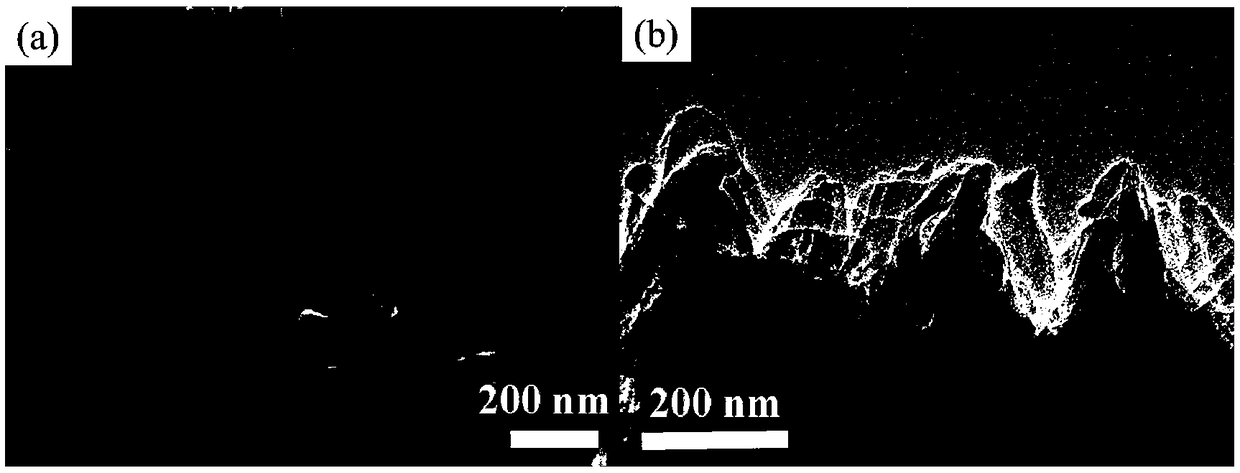

[0032] 1 g of ordered mesoporous carbon CMK-3 was ultrasonically mixed with 200 mL of 20% ethanol solution containing 2.8 g of aniline and 20 g of concentrated sulfuric acid for 20 min, and placed in a vacuum box at room temperature for 1 h. The resulting suspension was transferred to an ice-water bath, and 200 mL of 20% ethanol solution without aniline and sulfuric acid was added rapidly. 1 mL, 6.44 g / mL ammonium persulfate solution was added dropwise under stirring condition, and stirring was continued at 0° C. for 5 h. The resulting blue-green suspension was suction-filtered, washed three times with deionized water and ethanol, and dried in an oven at 60°C. The SEM image of the obtained polyaniline / ordered mesoporous carbon composite image 3 shown.

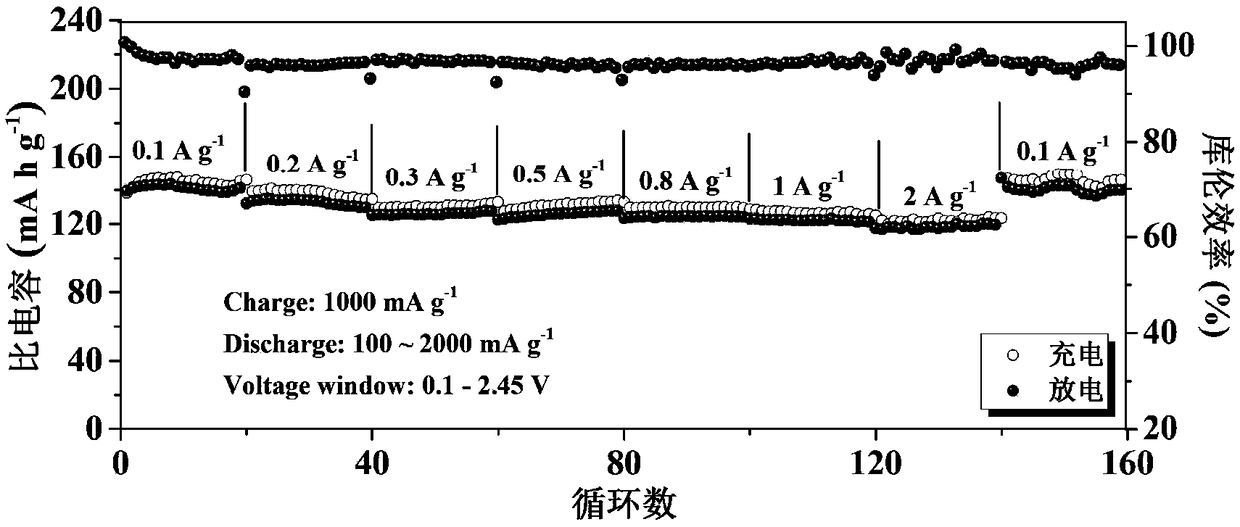

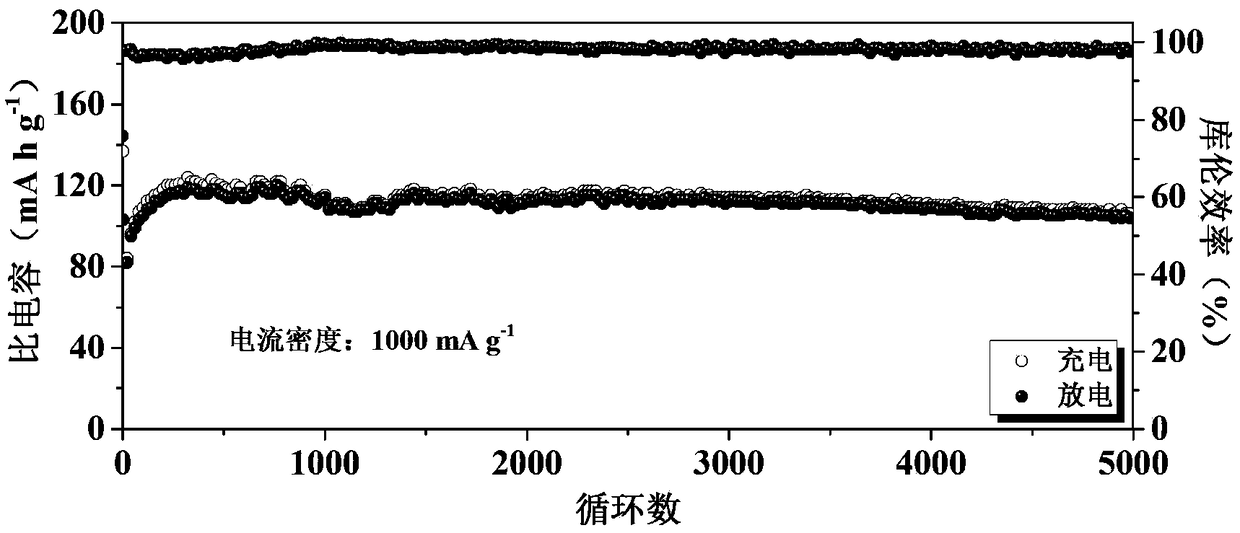

[0033] 30 mg of the above polyaniline / ordered mesoporous carbon composite material, 3.75 mg of PVDF, and 3.75 mg of conductive carbon black were uniformly mixed and ground for 20 min, dispersed in 1 mL of NMP solution, and u...

Embodiment 2

[0038] 1 g of ordered mesoporous carbon CMK-3 was ultrasonically mixed with 200 mL of 20% ethanol solution containing 2.8 g of aniline and 20 g of concentrated sulfuric acid for 20 min, and placed in a vacuum box at room temperature for 1 h. The resulting suspension was transferred to an ice-water bath, and 200 mL of 20% ethanol solution without aniline and sulfuric acid was added rapidly. 1 mL, 6.44 g / mL ammonium persulfate solution was added dropwise under stirring condition, and stirring was continued at 0° C. for 5 h. The resulting blue-green suspension was suction-filtered, washed three times with deionized water and ethanol, and dried in an oven at 60°C.

[0039] 120mg of the above polyaniline / ordered mesoporous carbon composite material, 15mg of PVDF and 15mg of conductive carbon black were uniformly mixed and ground for 30min, dispersed in 5mL of NMP solution, and ultrasonically dispersed for 30min. Take 550 μL of the above-mentioned uniformly mixed liquid and add it ...

Embodiment 3

[0044] 1 g of ordered mesoporous carbon CMK-3 was ultrasonically mixed with 200 mL of 20% ethanol solution containing 2.8 g of aniline and 20 g of concentrated sulfuric acid for 20 min, and placed in a vacuum box at room temperature for 1 h. The resulting suspension was transferred to an ice-water bath, and 200 mL of 20% ethanol solution without aniline and sulfuric acid was added rapidly. 1 mL, 6.44 g / mL ammonium persulfate solution was added dropwise under stirring condition, and stirring was continued at 0° C. for 5 h. The resulting blue-green suspension was suction-filtered, washed three times with deionized water and ethanol, and dried in an oven at 60°C.

[0045] 30 mg of the above polyaniline / ordered mesoporous carbon composite material, 3.75 mg of PVDF, and 3.75 mg of conductive carbon black were uniformly mixed and ground for 20 min, dispersed in 1 mL of NMP solution, and ultrasonically dispersed for 30 min. Take 50 μL of the above-mentioned mixed homogeneous liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com