Treatment method of aluminum-containing waste acid

A technology for waste acid and aluminum waste, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of low economic benefits and generate more industrial solid waste, and achieve high economic benefits, complete recovery, and treatment. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

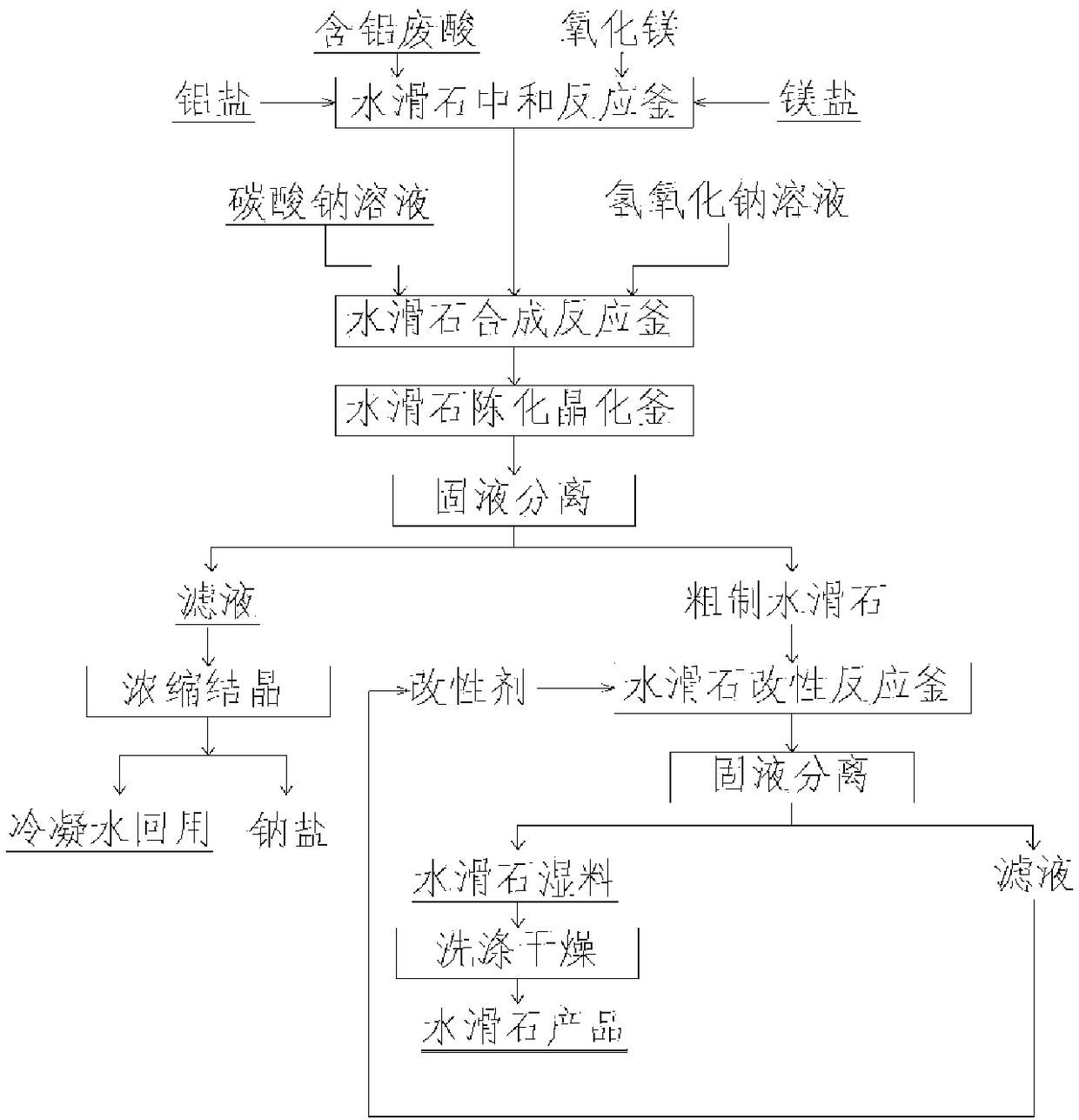

Method used

Image

Examples

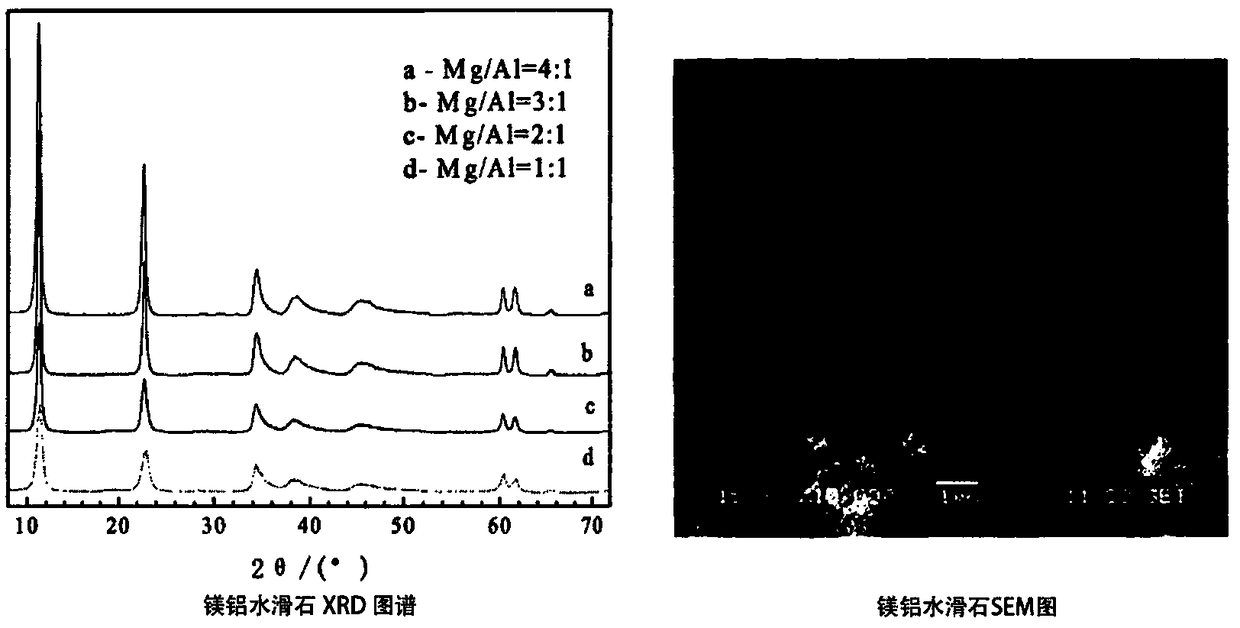

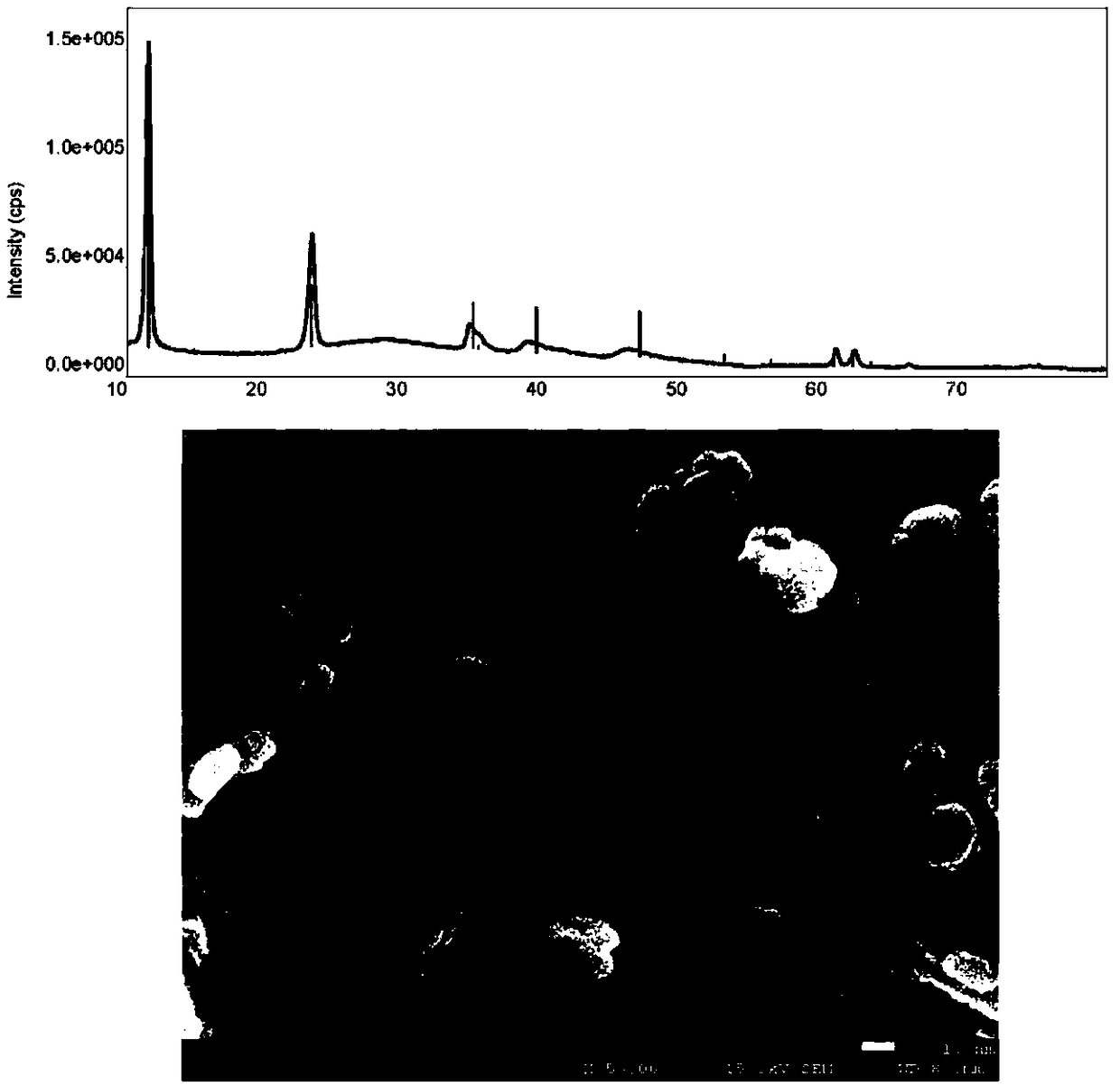

Embodiment 1

[0045]The hydrogen ion concentration is 1.5mol / L, the aluminum ion concentration is 0.7mol / L, the cobalt ion concentration is 0.0038g / L, the nickel ion concentration is 0.0078g / L, the manganese ion content is 0.357g / L, and the copper ion content is 0.186g / L 1. Put aluminum-containing waste sulfuric acid with an iron ion content of 1.02g / L in the neutralization reactor, under the condition of strong stirring at 250-350rpm, add heavy magnesium oxide slurry with a quality of 95% to neutralize until the pH value of the solution is 2.0 . Use magnesium sulfate solution to adjust the molar ratio of magnesium to aluminum in the neutralizing solution to be 2.5:1. Prepare 1mol / L sodium carbonate solution and 2mol / L sodium hydroxide solution. Under the stirring condition of 50-120rpm, the temperature is controlled at 60°C, the magnesium-aluminum mixed solution and the sodium carbonate solution are added to the synthesis reaction kettle in parallel, and the pH value of the system is adju...

Embodiment 2

[0047] Take aluminum-containing waste sulfuric acid with a hydrogen ion concentration of 5mol / L, an aluminum ion concentration of 0.5mol / L, a manganese ion content of 0.147g / L, a copper ion content of 0.096g / L, and an iron ion content of 0.087g / L in the neutralization reaction In the kettle, under the condition of strong stirring at 250-350rpm, add light magnesia slurry with a quality of 99% to neutralize until the pH value of the solution is 1.0. Use sodium metaaluminate solution to adjust the molar ratio of neutralizing liquid magnesium to aluminum to 1:1. Prepare 2mol / L sodium carbonate solution and 3.5mol / L sodium hydroxide solution. Under the stirring condition of 50-120rpm, the temperature is controlled at 80°C, the magnesium-aluminum mixed solution and the sodium carbonate solution are added to the synthesis reaction kettle in parallel, and the pH value of the system is adjusted to 12 with sodium hydroxide to carry out the hydrotalcite synthesis reaction. The synthesiz...

Embodiment 3

[0049] The hydrogen ion concentration is 3.16mol / L, the aluminum ion concentration is 0.71mol / L, the zinc ion concentration is 0.41g / L, the manganese ion content is 0.27g / L, the copper ion content is 0.12g / L, and the iron ion content is 1.40g / L The aluminum-containing waste hydrochloric acid is placed in a neutralization reactor, and under the condition of strong stirring at 250-350rpm, it is neutralized by adding light magnesia slurry with a quality of 90% to a pH value of 0.8. Use aluminum hydroxide slurry to adjust the molar ratio of neutralized liquid magnesium to aluminum to 2:1. Prepare 0.5mol / L sodium carbonate solution and 1.5mol / L sodium hydroxide solution. Under the stirring condition of 50-120rpm, the temperature is controlled at 90°C, the magnesium-aluminum mixed solution and the sodium carbonate solution are added to the synthesis reaction kettle in parallel, and the pH value of the system is adjusted to 11 with the sodium hydroxide solution to carry out the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com